REF0717-2

11

Description

2

2.7 Chassis

Both legs can be spread out to make room for obstacles e.g. a chair. The legs are electrically

adjustable by the buttons on the hand control. It’s advisable to transfer as much as possible with the

legs in the narrow position to prevent damage to the hoist or surrounding area.

2.7.1 Adjusting the legs of the Hoist

Make sure there is enough space to spread the legs. If the legs get stuck, this can damage the

hoist or its environment.

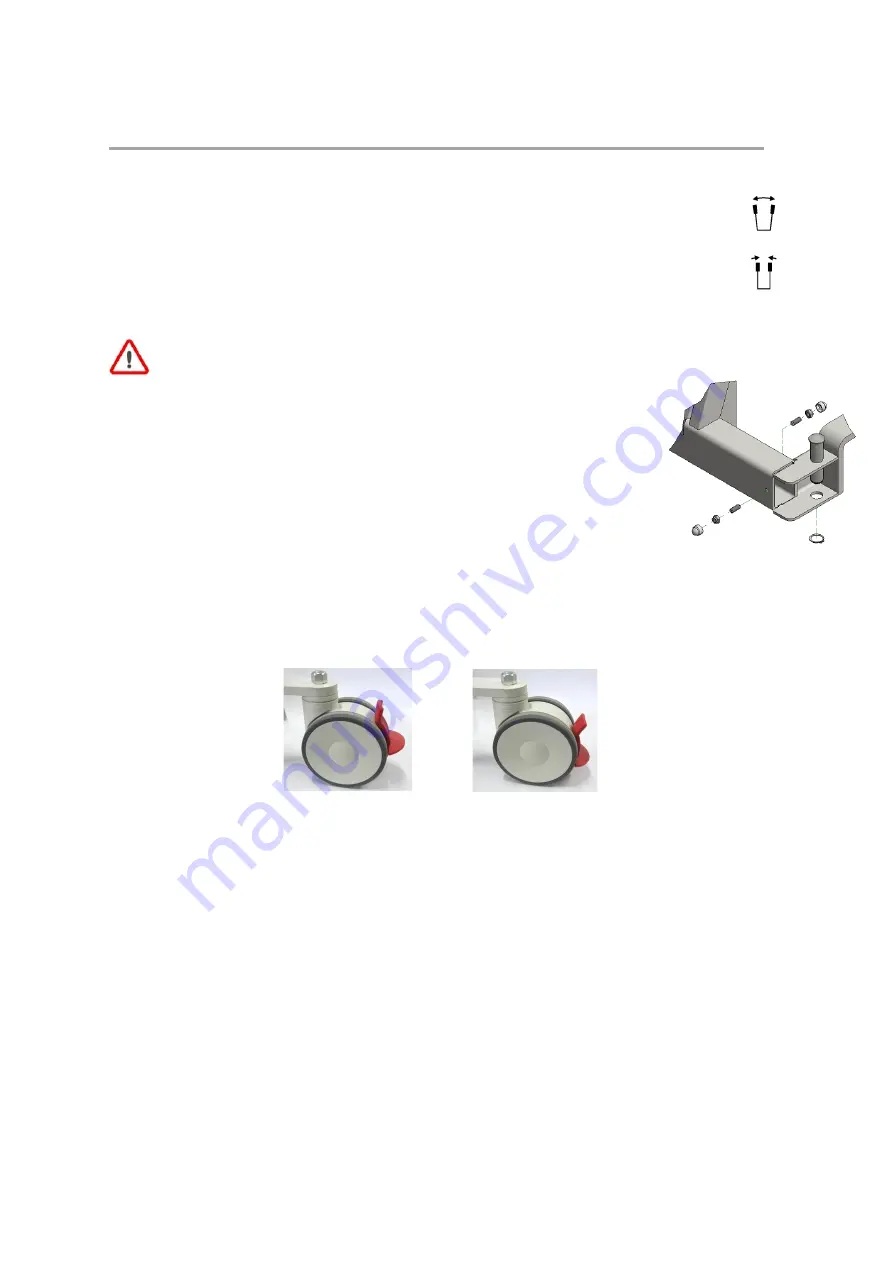

If parts of the leg adjustment need to be replaced, make sure that the legs are properly

adjusted. On the front and back of the frame next to the legs are set screws that remove

movement from the legs in the extreme positions. Loosen these set screws. Let the

motor run completely. Then adjust the legs perpendicular to the frame by turning the

M10 ball joints in or out of the frame. With the set screws you can remove the remaining

movement in both extreme positions. Do not over tighten!

This prevents problems with the motor or ball heads.

2.7.2 Wheels

The hoist has four swivel wheels, braked 100mm at the front and 125mm at the rear. The rear wheel brake

stops the wheel from rolling and the direction of rotation. Apply the brake using the tip of the foot. Always do

this with care.

The wheels have a very low rolling resistance due to the fully ball-bearing pivot points.

Moving the hoist from a standstill requires minimal force if the wheels of the chassis are already in line with

the direction of travel.