035-19624-001 Rev. A (0104)

Unitary Products Group

17

ROLLOUT SWITCH CONTROLS

These controls are mounted on the burner box assembly. If the temper-

ature in the burner box exceeds its set point, the ignition control and the

gas valve are de-energized. The operation of this control indicates a

malfunction in the combustion air blower, heat exchanger or a blocked

vent pipe connection. Corrective action is required. These are manual

reset controls that must be reset before operation can continue.

PRESSURE SWITCHES

This furnace is supplied with a pressure switch, which monitors the flow

through the combustion air/vent piping system. This switch de-ener-

gizes the ignition control module and the gas valve if any of the follow-

ing conditions are present. Refer to Figure 25 for tubing connections.

1.

Blockage of combustion air piping or terminal:

•

Low fire (1LP)

•

High fire (2LP)

2.

Blockage of vent piping or terminal.

•

Low fire (1LP)

•

High fire (2LP)

3.

Failure of combustion air blower motor.

•

Low fire (1LP)

•

High fire (2LP)

4.

Blockage of condensate drain piping.

•

Low fire (1LP)

•

High fire (2LP)

LIMIT CONTROLS

There is high temperature limit control located on the furnace vestibule

panel near the gas valve. This is an automatic reset control that pro-

vides over temperature protection due to reduced airflow, that may be

caused by a dirty filter, or if the indoor fan motor should fail. The control

module will lockout if the limit trips 3 consecutive times.

SECTION IX: START-UP AND

ADJUSTMENTS

The initial start-up of the furnace requires the following additional

procedures:

IMPORTANT:

All electrical connections made in the field and in the fac-

tory should be checked for proper tightness.

When the gas supply is initially connected to the furnace, the gas piping

may be full of air. In order to purge this air, it is recommended that the

ground union be loosened until the odor of gas is detected. When gas is

detected, immediately retighten the union and check for leaks. Allow

five minutes for any gas to dissipate before continuing with the start-up

procedure.

TOOLS AND INFORMATION THAT WILL BE

REQUIRED IN ORDER TO PROPERLY PERFORM THE

FURNACE STARTUP PROCEDURE.

1.

Call the local gas supplier to obtain heating value of the natural

gas. If you cannot obtain the heating valve of the gas from the gas

supplier, you may use a default value of 1030 BTU/SCF (38.8 MJ /

m³).

2.

You will need a thermometer or portable digital thermometer to

read the supply and return air temperatures.

3.

You will need a U-tube manometer or digital equipment that has

the ability to read pressures between 0 – 15” in.w.c (0 - 3.73 kPa)

in order to measure the gas line and the manifold pressures.

4.

You will need 2 pieces of 1/4” (6.35 mm) ID flexible tubing that are

12” (30cm) in length and 1/4” (6.35 mm) tee to connect the U-tube

manometer or the difital pressure measuring equipment to the gas

valve pressure ports.

There is an accessory kit (1PK0601) available from Source 1, which

has the following items:

•

1 - 12” (30 cm) length x 1/8” (3.175 mm) diameter tubing

•

2 – pieces of 4” (10 cm) length x 1/8” (3.175 mm) diameter tubing

•

1 - 5/16” (7.94 mm) tee

•

1 – 5/16” (7.94 mm) x 1/8” (3.175 mm) reducing coupling

•

1 – 1/8” (3.175 mm) adapter

There is a accessory kit (1PK0602) available from Source 1, which has

the following items:

•

1 - 12” (30 cm) length x 1/8” (3.175 mm) diameter tubing

•

2 – pieces of 4” (10 cm) length x 1/8” (3.175 mm) diameter tub-

ing

•

1 - 5/16” (7.94 mm) tee

•

1 – 5/16” (7.94 mm) x 1/8” (3.175 mm) reducing coupling

•

1 – 1/8” (3.175 mm) adapter

•

1 - Dwyer – Manometer

These items are required in order to properly perform the required star-

tup procedure.

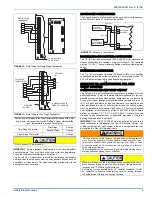

FIGURE 25:

Pressure Switch Tubing Routing

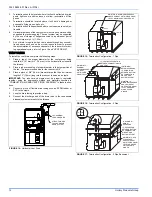

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

Perform the following procedures only after the condensate trap

has been properly piped to a drain connection using the procedure

in this instruction.