- 29 -

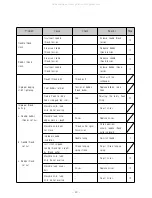

Problem

Cause

Check

Solution

Page

Needle thread

slack.

Insufficient needle

thread tension

―

Increase needle thread

tension.

12

Excessive needle

thread tension

―

Decrease bobbin

thread tension.

12

Bobbin thread

slack.

Excessive needle

thread tension

―

Decrease needle

thread tension.

12

Insufficient needle

thread tension

―

Increase bobbin thread

tension.

12

Improper looping

stitch tightening

Rough thread path

Thread path

Polish with fine

sandpaper.

Poor bobbin rotation

Tension of bobbin

thread leader

Replace bobbin, rotary

hook.

Rotary hook to rotary

hook stop gap too small

Gap

Adjusting the rotary hook

timing.

20

Improper thread

cutting

a. Needle, bobbin

threads not cut

b. Needle thread

not cut

c. Bobbin thread

not cut

Movable knife, fixed

knife do not overlap.

―

Adjust knives

Movable, fixed knife

edges worn or rough.

Knives

Replace knives.

Movable knife does

not move

Thread cutter signal

transmission

Check electrical

circuits; replace thread

cutter solenoid.

Improper needle

installation

Needle facing

Reinstall needle.

7

Last stitch skipped,

needle thread not caught

by thread cutter.

Thread take-up

spring stroke

Adjust thread take-up

spring.

Movable knife, fixed

knife do not overlap

―

Adjust knives.

15

Movable, fixed knives

dull.

Knives

Replace knives.

15

Movable knife, fixed

knife do not overlap

―

Adjust knives.

15

All manuals and user guides at all-guides.com

Содержание DB2-H515

Страница 2: ...All manuals and user guides at all guides com...

Страница 4: ...5 off A S 31 2 40 25 OFF A S A S All manuals and user guides at all guides com...

Страница 34: ...24 7 7 20 20 20 10 9 7 7 12 12 16 23 All manuals and user guides at all guides com...

Страница 36: ...26 7 7 1 7 9 20 20 20 13 16 All manuals and user guides at all guides com a l l g u i d e s c o m...

Страница 38: ...28 12 12 12 12 puff 20 7 15 15 15 All manuals and user guides at all guides com...

Страница 40: ...30 13 1 13 All manuals and user guides at all guides com...

Страница 42: ...32 All manuals and user guides at all guides com...