34

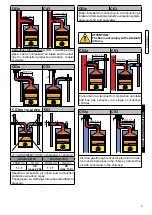

ROUTINE YEARLY VERIFICATION OPERATIONS

COMPONENT:

VERIFY:

CONTROL/INTERVENTION

METHOD:

FL

(domestic hot water

priority flow switch

( 2 )

Is the minimum domestic hot water

flow rate 3 l/min.?

The burner must ignite with an

intake above or equal to: 3 l/min.

VG

(Gas valve)

( 3 )

Does the valve modulate properly?

Open a hot water tap at maxi-

mum flow rate and then at min

-

imum. Make sure that the flame

modulates.

SR (heating sensor)

( 11 )

SS (domestic hot water sensor)

( 1 )

SSR (return sensor)

( 22 )

Do the sensors maintain the

original characteristics?

12571 ohm at 20° C / 1762 ohm

at 70° C.

Measurement to be taken with

the wires disconnected (see

table Res/Temp).

E ACC/RIV. (ignition/detection

electrode)

( 4 )

Does the discharge of sparks before

putting the boiler in safe conditions last

less than 10 sec.?

Detach the electrode ionisation

wire and check the securing

time.

TL (anti-overheating

limit thermostat)

( 10 )

Does the TL put the boiler in safety

conditions when overheating?

Heat the TL until it intervenes

at 95°C and check that it inter-

venes at 95°.

DK (safety pressure switch

against water deficiency)

( 13 )

Does the pressure switch block the

boiler

if the water pressure is below 0.4 bar?

Without request: close the shut-

off valves of the heating circuit,

open the drain valve to make the

water pressure decrease. Before

pressurising again, check the

pressure of the expansion vessel.

Expansion vessel

( 8 )

Does the vessel contain the right

amount

of air?

Check the pressure in expansion

vessel (1 bar when the boiler

is empty). Pressurise the boiler

(open the pump automatic vent

valve). Open the heating circuit

closing valves.

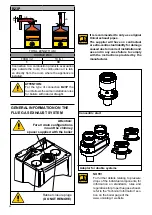

Condensation drain trap

(26)

Has the trap got deposits on the

bottom?

Clean the trap with water.

Domestic hot water flow rate

Filter in cold water inlet

( 2 )

Clean the filter with limescale

remover.

Heat exchanger body

(24 )

1) Measure the Thermal Capacity

using a meter and compare the val

-

ue with that contained in table 3.12.

The data measured indicates if the

exchanger needs cleaning.

2) Check that the space between

the rungs of the exchanger are not

clogged

It is recommended to use the

products purposely created by

Unical (see system protection

ACCESSORIES sect. in the

domestic price list), being care-

ful to wash the area with most

rungs first (lowest part visible

from above) and then the upper

part if necessary.

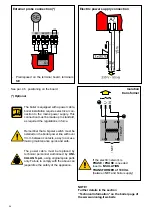

Burner

( 5 )

Check the state of cleanliness of the

burner mesh

Remove any deposits using

compressed air, blowing from

the mesh side.

( Num ) =

see key Par. 2.2