34

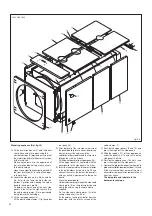

Detail 1:

Fit the brush handle extension

onto the turbulator remover

Withdraw the pin from turbulator.

Detail 2:

Fit the pin in the radial hole with a hammer.

Detail 3:

Screw the turbulator remover onto the

turbulator.

Detail 4:

Turn up to unblock the turbulator.

Detail 5:

Withdraw the turbulator

Detail 6:

Turn the remover counterclockwise to release

the turbulator

The procedure from detail 3 to 6 has to be repeated for all the turbulators.

Turbulators removal

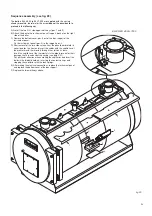

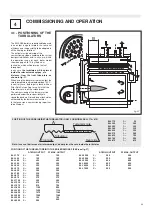

4.2 - PRELIMINARY CHECK

Once all the hydraulic, electrical and fuel

connections have been made, before starting the

boiler we suggest to ascertain that:

- The expansion vessel and the pressure

relief valve are correctly connected and are

in no way interceptable.

- The bulb of thermometer, working, high limit

and minimum thermostats are well secured

into their proper bulb holder.

- The turbulators are correctly fitted in all the

smoke pipes.

- The C.H. circuit has been washed and rinsed

and is free from solid impurities.

- The C.H. circuit is filled with water and has

been completely purged.

- The pumps operate properly.

- The flow switch, the pressure relief valve,

and the overheating discharge valve, if any,

are adjusted at the right value.

- The fuel, hydraulic, electrical and safety

connections are executed in conformity with

national and local requirements in force.

- There are no water leaks.

- The burner has been fitted according to the

instructions of the burner

manufacturer.

- The mains voltage and frequency are

compatible with the burner and the

electrical equipment of the boiler.

- The burner is adjusted for the fuel type,

among those listed in the burner data plate,

available on the installation site, and the

burner output range is compatible with the

boiler output.

- In the boiler house there are also the burner

instructions.

- The C.H. pipes are properly insulated.

- The C.H. system is capable to absorb the

heat quantity produced at the first start of

the burner, during the test period.

-

The shunt pump is installed as

prescribed in the paragraph 2.5.6.

4.3 - FIRST COMMISSIONING

At the commissioning stage of the boiler a

qualified technician has to perform the

following checks:

- Internal and external sound test of burner

and fuel feeding pipe;

- Adjustment of the fuel throughput according

to the nominal input of the boiler (it is

convenient to remember that the nominal

input can be adjusted between the minimum

and the maximum shown in the table of

pages 6 to 10), by sharing the output between

the 1st and the 2nd stage, knowing that the

1st stage flame can go down to the 60% of

the nominal output (which at its turn can vary

between the minimum and the maximum

depending on the output

requested by the C.H. system).

Proceed, then, in the following way:

- Open the fuel feeding cock and check that

there are no leaks in the feeding line.

- Ascertain that all the switches of the

panel board are in OFF position and adjust

the working thermostat to the minimum

position.

- Switch ON the panel board through the

main switch.

- Switch ON the C.H. pump: it will start to

rotate as soon as the minimum water

temperature thermostat detects 50°C.

- Switch the burner ON.

- Position the working thermostats of 1st and

2nd stages to the maximum setting to create

a heat request.

During this phase check that:

- There are no smoke leaks from the front

door, the burner plate and the chimney

connection.

- There is a draught at the chimney base

between 2 and 4 mm w.g.

- There are no water leaks.

- The different thermostats and the other

installation safety devices work properly.

- The shunt pump operates correctly.

- The burner ignition is good.

- The burner characteristics (main

adjustments and nozzle type) correspond

to the boiler data plate.

With a burner properly adjusted it must be

possible to reach easily, from a smoke sample

taken at the chimney base, the values given

below:

1) With light oil having a maximum viscosity

of 1.5 °E at 20 °C:

- CO

2

= 12 to 13 %

- Smoke index < 1

- Smoke temperature = 190 to 210 °C

2) With Natural Gas:

- CO

2

= 9 to 10 %

- Smoke temperature = 180 to 200 °C

(values related to a clean boiler, with water

at 70 °C).

It is suggested to adjust the fuel throughput to

the actual needs of the C.H. installation (avoid

to overcharge the boiler), without

exceeding the a.m. smoke temperatures

(never go below 160 °C).

fig. 38

Содержание ELLPREX Series

Страница 1: ...26739 01 13 rev 4 ELLPREX INSTALLATION USE AND SERVICING INSTRUCTION to be kept by the user...

Страница 37: ...37 Notes...

Страница 38: ...38 Notes...

Страница 39: ...39 Notes...