12 UNIBLOC-PD Operation & Service Manual: PD501-576

3.0 Shaft Seal Service

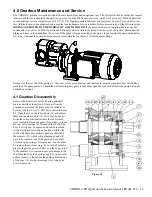

To aid in the removal and installation of the shaft seals, plastic

mounting sleeves that are the same diameter as the shafts at the seal

area are available. The mounting sleeves also protect the seals from

the shaft splines. Contact an authorized service center, or Uni-

bloc-Pump, to obtain these tools.

Before proceeding with the following steps,

DISENGAGE POW-

ER TO THE HYDRAULIC OR PTO DRIVE

. If the pump is con-

nected to piping, depressurize the system and close valves on both

the suction and discharge sides to isolate the pump from the rest of

the system. Disconnect the piping from the pump.

Remove the front cover nuts (16) and the front cover (2). Place a

nonmetal object between the rotors (3a,3b) to keep them from turn-

ing. Unscrew the rotor bolts (14a,14b) and then slide the rotors off

the shafts. If the rotors will not slide off they can be removed simul

-

taneously with the rotor housing (1). Unless they are being replaced,

DO NOT USE PLIERS OR CHANNEL LOCKS TO REMOVE

THE ROTORS

. They will be damaged. See the following sections

for further instructions to remove the rotor housing.

Figure 3.0

3.1 Double O-Lip

TM

Seal

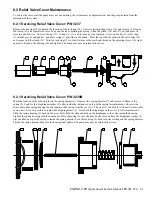

This type of seal is most frequently used with liquids that are very difficult to seal because of high viscosity. The seal comes as a

single cartridge that is easily serviced. The maximum shaft rotational speed for this seal is 1.5 m/s (4.8 ft/s), or 500 rpm, and the

maximum service pressure should not exceed 10 bar (150 psig). The seal does not require external lubrication and can be run dry

for short periods. This seal comes as standard on UNIBLOC 501, 551, 576.

3.1.1 Double O-Lip

TM

Seal Removal

If the rotors were removed, the rotor housing does not need to be taken off.

The seal cartridges (61) can be removed by placing screwdrivers between

the rotor housing and gearbox and pushing them out. Be aware that the

wear sleeve (80) can slide off with O-lip seal when removing the seal car

-

tridge (61).

3.1.2 Double O-Lip

TM

Seal Installation

Check the shaft sleeves for wear. If grooves are noticeable, they may have

to be replaced. Place new o-rings (49) into the groove of the seal cartridges.

Clean the rotor housing seal bores. Apply product compatible lubricant to

the bores and the shafts. Slide the assembly sleeves on the splined shaft

ends. These must be used to prevent damage to the O-lip seal. Push the seal

cartridges (61) in, lip side last, so that they are flush with the back of the

rotor housing. See section 3.3 for completing the installation.

Figure 3.1

Содержание UNIBLOC-PD 501

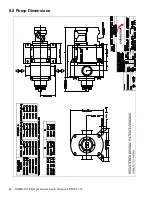

Страница 26: ...26 UNIBLOC PD Operation Service Manual PD501 576 8 0 Pump Dimensions UNIBLOC PUMP ...

Страница 27: ...UNIBLOC PD Operation Service Manual PD501 576 27 UNIBLOC PUMP ...

Страница 28: ...28 UNIBLOC PD Operation Service Manual PD501 576 UNIBLOC PUMP ...

Страница 30: ...30 UNIBLOC PD Operation Service Manual PD501 576 UNIBLOC PUMP 9 0 Parts Lists ...

Страница 31: ...UNIBLOC PD Operation Service Manual PD501 576 31 UNIBLOC PUMP ...

Страница 33: ...UNIBLOC PD Operation Service Manual PD501 576 33 3 ...

Страница 34: ......

Страница 35: ......