11

5.

4B

OPERATING PROCEDURE

5.1.

22B

Cautions in Operation

(1)

When power is applied to this instrument, measurement starts about three seconds later. However,

start measurement more than 30 minutes after turning power ON until the indicated value is

stabilized because there can be temperature drift or other problem for some time after power is

turned ON.

If the sensor head is used to measure low pressure (for example, CMMT-10A) or if an effective

digit below 1/1000 of the full scale of the sensor head is required, start measurement after applying

power continuously for more than 2 hours until temperature equilibrium of the sensor head is

attained.

Do not turn the power OFF when a series of measurements is being made.

(2)

This controller uses an absolute pressure type vacuum gauge of which measurement value is not

affected by the type of gas, but its characteristics may change if the sensor head is exposed to a

chemically active gas or a gas with high adsorptivity.

(3)

Refer to the following table, the proof pressure of the sensor head, including when power is not

applied.

Usage environment precautions

Do not connect the sensor outside the VCO, VCR, UFC joint specification in a

location where the sensor's internal pressure exceeds atmospheric pressure. If the

sensor's internal pressure exceeds atmospheric pressure, it may pose a hazard to

its surroundings, including to people, if the gauge head flies off its connector.

There is also a risk of malfunction or damage to the sensor if the sensor interior

exceeds the maximum usable pressure. Where there is a risk of exceeding the

maximum usable pressure, ensure that the sensor interior will not exceed the

maximum usable pressure with a gate valve.

Model

CCMT-1000A

CCMT-100A

CCMT-10A

Maximum usable

pressure

160 kPa (abs)

Atmospheric

pressure

Atmospheric

pressure

Model

CCMT-1000D

CCMT-100D

CCMT-10D

CCMT-1D

Maximum usable

pressure

400 kPa (abs)

260 kPa (abs)

260 kPa (abs)

260 kPa (abs)

(4)

Before starting measurement, it is necessary to correct the zero point at a pressure sufficiently lower

than the measurement pressure. If the ultimate pressure of a system to which the sensor head is

attached is not sufficiently low for zero point correction, the specifications of this instrument may

not be met.

(5)

The zero point correction is made by using the 0 ADJ function of the sensor head in conjunction

with the zero point correcting function of this controller. The zero adjusting function of the sensor

head is for coarse adjustment and that of this controller is for fine adjustment.

The zero point correcting function of this controller is reset by turning the power OFF. So keep this

in mind during operation.

Содержание GM-2001

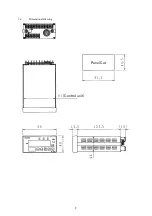

Страница 9: ...3 1 4 Dimensional drawing Panel Cut Control unit...

Страница 12: ...6 Fig 2 2 Rear panel...

Страница 28: ...22 10 9BCertificate of Contamination...