16

9. MAINTENANCE AND SPARE PARTS

9.1 Spare parts

Table of water circuit, electrical and electronic spare part numbers

part number

pos.

fig.

Water circuit

Fill solenoid valve kit

UP_P_0558

F

9.a

Drain solenoid valve kit

UP_P_0559

E

9.a

Water circuit (UP01)

Tank complete

UP_P_0560_1

B

9.a

Cover with fan and level sensor

UP_P_0561_1

L

9.a

Water circuit (UP02)

Tank complete

UP_P_0562_2

B

9.a

Cover with fan and level sensor

UP_P_0563_2

L

9.a

Electrical and electronic parts

Main electronic board

UP_P_0560

D

9.a

Main board + auxiliary card

UP_P_0561

D + H 9.a

Driver

UP_P_0562

Transducer TDK

UP_P_0563

Electrical parts -

(UP01 - UP02)

Power transformer:

115-24V

UP_P_0564

A

9.a

Power transformer:

115-50V

UP_P_0565

A

9.a

Cable Kit UU01F

UP_P_0566

G

9.a

Cable Kit UU01G

UP_P_0567

G

9.a

Tab. 9.a

B

L

A

E

H

D

F

G

Fig. 9.a

9.2 Tank cleaning and maintenance

Replacement

Important:

replacement must only be carried out by qualified

personnel, with the humidifier disconnected from the power supply.

In normal conditions, the

tank requires maintenance after one year

(or 1500/5000 operating hours respectively with mains/demineralised

water), or

if not used for an extended period

. Replacement is required

immediately – even before the scheduled period – should problems

occur (for example, when scale inside the tank prevents correct operation

of the piezoelectric transducers

).

Replacement procedure:

1.

switch the humidifier off (switch “0”), and open the mains disconnect

switch (safety procedure);

2.

disconnect the transducer power cable;

3.

release the tank (the two tabs at the rear) and lift it vertically to

remove it;

4.

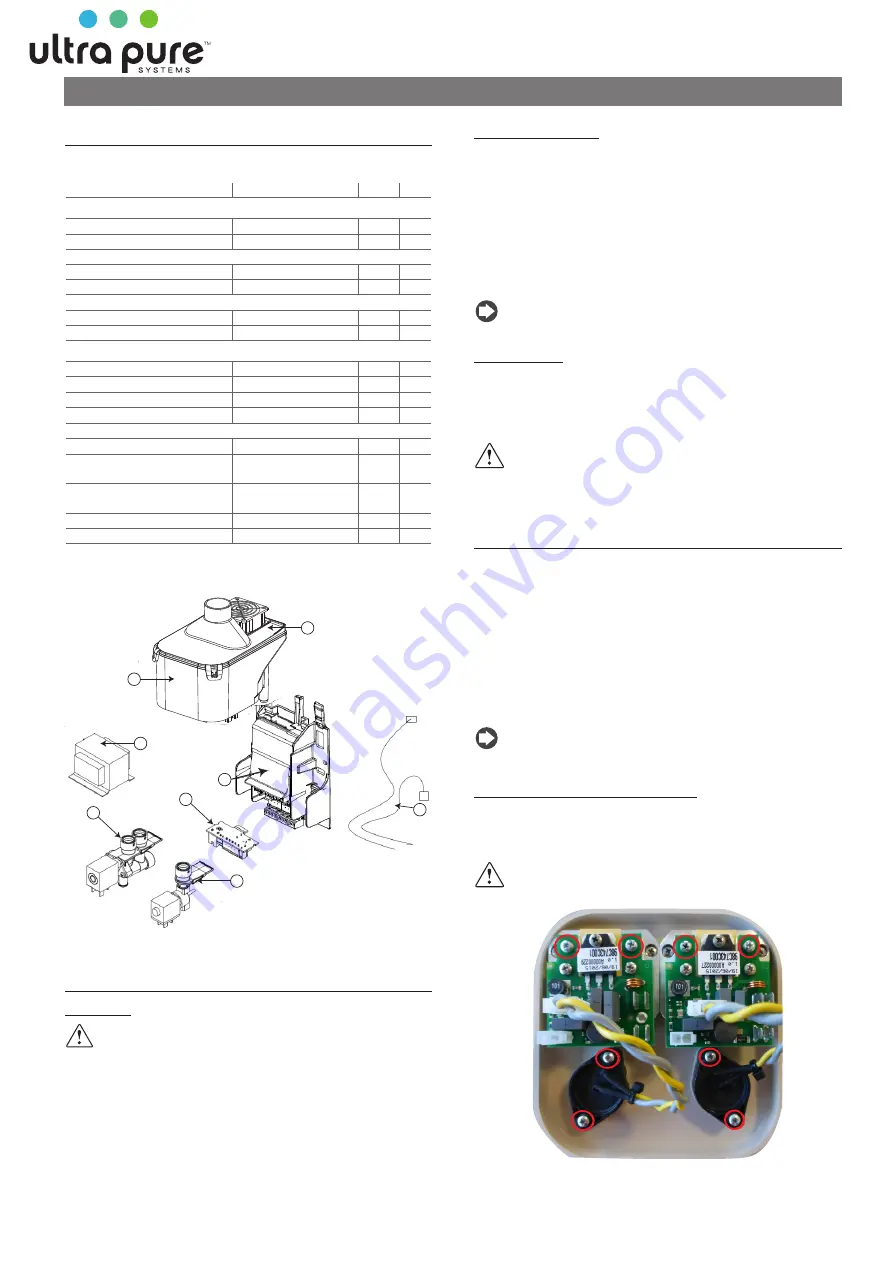

clean or replace the transducers by removing the screws, see Fig. 9.b

(after replacement test water-tightness by filling the tank manually)

5.

reconnect the transducer power cables;

6.

reposition the tank;

7.

switch the humidifier on.

Note:

the tightening torque of the screws that fasten the transducer

must be 0.2ft-lb-0.03ft-lb.

Periodical checks

•

Every year

or no more than 1500/5000 operating hours respectively

with mains/DI water:

- clean the piezoelectric transducers

-

make sure the level sensor slides freely

Important

: in the event of water leaks, disconnect the humidifier

from the power supply and repair the leak

9.3 Cleaning and maintenance of other

components

•

Ultra Pure humidifers work best with DI water. Each trasnducer will

operate approx. 10,000hrs proportionally. If RO or City water is used,

transducers useful life is reduced proportionally

•

When cleaning plastic parts do not use detergents/solvents;

•

To replace the drivers and transducers, loosen the screws shown in the

figure with a screwdriver. Before applying the new driver , spread on

the back of the heat sink in contact with the tank, a layer of conductive

paste. The lack of the conductive paste may cause malfunctions. To

insert new transducers, observing the direction of insertion (

please,

pay attention to the print before removing the old one).

Note:

the tightening torque of the screws that fasten the transducer

must be 0.02ft-lb-0.03ft-lb.

Maintenance checks on other components:

□

fill solenoid valve. After having disconnected the cables and hoses,

remove the solenoid valve, check the inlet filter and clean if necessary,

using water and a soft brush.

Important

: after having replaced or checked the water circuit

components, make sure the connections are restored correctly.

Fig. 9.b