6

OVERVIEW

The direct measurement of CO

2

is achieved using UEi’s own EOS technology sensor. CO

2

is set to zero in fresh air automatically after

the initial 60 second countdown.

If “ZERO CO

2

” is indicated, ensure the unit is in

outside fresh air

before selecting the “Purge” option.

It is very important that re-zeroing is done in

outside fresh air

as indoor CO

2

levels are affected by human breath.

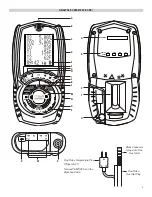

The analyzer has a protective rubber boot with magnets for hands-free operation and is supplied with a probe with an integral

temperature sensor.

A low flow detection system warns of a low flow and switches the pump off, this also helps prevent water condensate ingress from

overfilled water traps.

A large 6 line display provides the user with relevant information based on current activity including instrument status via the new

intelligent Status Bar. All data can be printed via an optional infrared printer.

The C161 uses a new data storage system allowing up to 30 logs of any combination of Combustion, AUX or Temperature tests, rather

than be restricted to an allowance of particular logs.

10 characters can be added to Line 1 of the header, 6 characters to Line 2 of Header of the printouts.

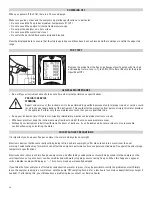

PRE TEST CHECKLIST

SETTING INLET TEMPERATURE

ANALYZER CONNECTIONS

• Turn on and zero the analyzer without the flue probe connected to use ambient temperature.

• Connect flue probe thermocouple to T1 during zero countdown use for inlet ducted system.

• Connect a thermocouple to T2 to measure second temp source.

• Clean particle filter

• Water trap and probe line are empty of water

• Power on and zero

• All hose and thermocouple connections are properly secured

• Flue gas probe is sampling ambient FRESH air

• Water trap is fitted correctly to the instrument

• Flue temperature plug is connected

• Ensure water trap plug is inserted correctly

WARNING!

Turning the pump off while the probe is in the flue will leave toxic gases

inside the analyzer. Once data has been printed or copied, it is advisable

to purge the unit with fresh air as soon as possible. To do this remove the

probe from the flue and turn ON pump. Always allow the readings to return

to zero (20.9% for O

2

) prior to shutting the unit off. The meter will not switch

off until the CO reading is below 20 ppm.

WARNING!

The probe will be hot from flue gases. Remove the probe from the flue and

allow it to cool naturally. Do not immerse the probe in water, as this will be

drawn into the analyzer and damage the pump and sensors.

NOTE:

Take care when

inserting the temperature

probes as the pins are

polarized. Insert with the

smaller pin (+) to the right.

T2

T1