1

revised 09/09

Smog-Hog

SG Series Model

1. HOW THE SMOG-HOG SG SERIES

WORKS

the SG is a self-contained air cleaning system which

removes dry or oily airborne con taminants from

industrial work areas. operating on the principle of

electrostatic precipitation, it pulls air past a mechanical

prefilter, charges and collects airborne particulate, then

exhausts clean air to the environment.

Prefilters serve the dual purpose of trapping large

particulate and diffusing the airstream evenly into

precipitator components at low, controlled velocity.

air passes through an ionizing section, where nearly

all particulate is charged, then on to a collecting

section where charged particles are repelled from

similarly charged plates and drawn to ground plates.

agglomerated particles separated from collection plates

during unit start-up are trapped on an after filter, allowing

clean air to pass through the system blower at all times.

SG units may be ducted directly to the contaminant

source or unducted to remove particulate from the

general environment. units are gen erally suspended

from the ceiling but may be cradle or skid mounted to

suit the application. units without blowers are supplied

where air is moved through the units by others.

The Smog-Hog SG uniquely combines high airflow

and high efficiency. its compact “unicell” design

helps minimize contaminant by-pass. it is suitable for

operation with or without in-place cleaning. all SG units

supplied with blowers have ad justable louvers to direct

exhaust air as required.

ionizing and collecting sections operate on high Dc

(direct current) voltage and low amperage, yielding a

very low power consumption of 75 watts maximum per

power supply. the high voltage creates a powerful field

for trapping small to submicronic particles. at start-up,

the unit’s power supply charges each unicell while the

system blower begins to move air through the unit.

2. INSPECTION OF EQUIPMENT

upon receipt of your SMoG-HoG SG, check carefully

for possible shipping damage. (any damage to carton,

skid, etc., may be a warning to you that rough handling

has caused internal damage.) units supplied with

accessories, such as an in-Place cleaning System,

will arrive in multiple cartons. check cartons versus

bill of lading. the detergent container is shipped

independent of units.

notify your delivery carrier and enter a claim if any

damage is found.

3. INSTALLATION PLANNING

3.1 UNDUCTED OR AREA CAPTURE

consideration should be given to the placement of the

precipitator to maximize its effectiveness. The number

of units required to clean the air will depend on the

layout of the room and the con centration of pollutants.

Because it is necessary to develop proper airflow patterns,

the placement and number of precip itators should be as

suggested by uaS or your local representative.

3.2 DUCTED OR SOURCE CAPTURE

When your SG is used as a ducted source collector,

the enclosure or pick-up hood design is important for

adequate capture of con taminants. Drive pulleys and

belts have been selected to provide proper airflow at

the design static pressure specified. Pulleys and belts

should not be replaced without first contacting uaS

customer Service at 1-800-252-4647.

3.3 SPECIFICATIONS

Smog-Hog SG Series are self-contained, two-stage,

Penney-type, electrostatic precipitators complete

with fully interlocked, energy limiting uL “recognized

component” power packs, mechanical prefilters, unicell

construction (combination ionizer and collection cell),

afterfilters, indicator lights and interlock switches. all

models except those designated “X” are supplied

with motor/blower sets mounted in an integral blower

housing. All high voltage wiring is external to the

component enclosure.

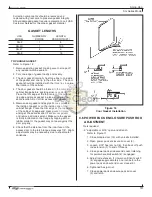

Figure 1

SG SERIES NOMENCLATURE

H HiGH PreSSure

M tanDeM

a in PLace cLeaninG

S StacKeD (2 on 2) ceLL

confiGuration

t tee SHaPeD confiGuration

X WitHout BLoWer

2 tWo uniceLLS

4 four uniceLLS

6 SiX uniceLLS

SMoG-HoG SerieS