USER GUIDE

Water Hookup

USER GUIDE

Door Swing 1

u-line.com

SAFETY •

INSTALLATION & INTEGRATION

• OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Water Hookup

PREPARE PLUMBING

The water valve uses a standard 1/4" (6.35 mm)

compression fitting. U-Line recommends using accessory

water hook up kit – part # ULAWATERHOOKUP. The kit

includes a 10' (3 m) braided flexible water supply line and

a brass hose fitting.

WARNING

!

Prior to installation, determine if this product

contains a gravity style drain or factory installed

drain pump. Products without a drain pump may

only use a gravity style drain. Failure to connect

water supply or drain line connections properly

may result in water leakage, personal injury,

and/or property damage. Disconnect power and

turn off water to the unit before attempting to

alter these connections. These connections are

the responsibility of the owner and must be

connected per local plumbing code. If you are

uncertain of how to safely and properly install

this product, contact a licensed plumber.

Water Supply Connection

WARNING

!

Connect to potable water supply only.

CAUTION

!

Review, obey, and understand the local

plumbing codes before you install your unit.

Connect to the cold water supply. The water

pressure should be between 20 and 120 psi (138

and 827 kPa). The water line MUST have a shut-

off valve on the supply line.

CAUTION

!

Do not use tape or joint compound when

attaching a braided flexible water supply line

that includes a rubber gasket. The gasket

provides an adequate seal – other materials

could cause blockage of the valve.

Failure to follow recommendations and

instructions may result in damage and/or

harm, flooding or void the product warranty.

CAUTION

!

Turn off water supply and disconnect electrical

supply to unit prior to installation.

Use caution when handling back panel. The

edges could be sharp.

1. Turn off water supply and disconnect electrical supply

to product prior to attempting installation.

2. Remove the grille/access panel in the front and the

back panel.

Do not use any plastic water supply line. The line

is under pressure at all times. Plastic may crack

or rupture with age and cause damage to your

home.

!

CAUTION

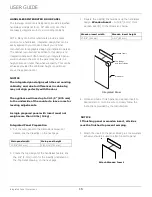

3. Locate water

valve in the front

of the unit and

thread water

supply line

through.

NOTICE

Route the water

supply line

through the unit so it does not come into contact

with any internal components other than the

solenoid valve. Normal operation creates some

vibration. A water supply line contacting an

internal component or cabinet wall can cause

excessive noise during operation or damage to

the line.

10