1-6

Section 1 - General Information

SERIAL NUMBER FORMAT

The serial number is divided into four segments. A typical

serial number is 089469-01-0002.

The first two digits of the first segment, 08, represents the

year the unit was made.

The next four digits of the first segment, 9469, represent the

shop order number. Order number 9469 is assigned for the

Model CLR2160 B-00 units.

The next two digit segment, 01, represents the month the unit

was made.

The last four digit segment, XXXX, is a factory internal

control number used at U-Line Corporation.

WARRANTY CLAIMS PROCEDURE

When submitting claims for warranty payment, please

follow these guidelines.

You can use any form you would normally use to bill your

customer (your own computer generated form, Narda, USA,

etc.). Claims can also be filed on-line at

www.u-lineservice.com.

The model and serial number

MUST

be on the claims. Claims

will not be paid without a model and serial number.

If you used a part in your repair, you

MUST

put the part

number, the invoice number and where the part came from.

Claims will be returned without this information.

If you work on more than one unit per service call please

submit a separate claim for each unit.

We track all defects through warranty claims, so please be

specific on what the repair was. If it is a system leak, please

specify where the leak was.

Please be sure the claim is legible. If the claim form cannot be

read, it will be returned, unpaid.

Remember:

Door and water level adjustments are 90 day

warranties only.

If you are changing out a unit please supply the model and

serial number of both units (the unit being replaced and the

new unit) and the R.A. number.

Occasionally the customer does not return their warranty cards. In

this case we use the date the unit was shipped to our distributor for

a beginning warranty date. This may cause the claim to be rejected

for a proof of purchase. If you want to check on a purchase date, you

may contact the U-Line Corporation Customer Assurance

Department at 1-800-779-2547. This will allow you to get a proof of

purchase, if needed, before you submit the claim.

At U-Line, parts and labor claims are paid separately. Included

in labor are freon and recovery charges, all other parts are

handled by the parts department. We require that some parts

be returned to us, so we may return them to our vendor. It

will be noted on your packing list if we require you to return

the part. If a part is to be returned please include a copy of the

packing list and a copy of your claim. If the part was purchased

at one of our part distributors, you must handle the part

warranty with that company. For labor payment please send a

readable copy of your claim to U-Line Corporation, P.O. Box

245040, Milwaukee WI, 53224-9540, or fax it to 414-354-

5696. Claims can also be filed on-line at www.u-

lineservice.com.

PROOF OF PURCHASE

Proof of Purchase and/or Proof of Install is an important part

of the warranty claim process. Sometimes it is difficult to

obtain a proper Proof of Purchase/Proof of Install for a

number of different reasons:

• The customer does not have a copy (only the original).

• The customer has only their copy of the final Walk Through or

sign-off of new construction.

• Other valid reasons that prevent your technician from leaving the

job site with a suitable Proof of Purchase/ Proof of Install.

We understand the problem and have modified our Proof of

Purchase policy to help you in these situations.

Effective immediately, if a copy of the Proof of Purchase/Proof

of Install is not available at the site, the technician should

record the following information on the Labor Invoice:

• The name of the selling Dealer

• The date of purchase/installation

• The Order or Invoice number (if available)

• The type of document they saw, i.e. Store Receipt, Closing Papers,

Sign-Off of Building Permit, Final Walk Through, etc.

If we have this information on the Labor Invoice, and we have

the other information that is needed

(correct Serial

Number, type of repair, time spent on repairs, etc.)

,

we will be able to process the invoice for you in a timely

manner.

09 67167-12-0002

Year

Month

Shop

Order

Number

Factory

Internal

Control

Number

Содержание BI95FCB

Страница 9: ...1 8 Section 1 General Information This page intentionally left blank...

Страница 27: ...3 12 Section 3 Service and Repair THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 29: ...4 2 Section 4 Parts U LINE ICE MAKER ASSEMBLY...

Страница 61: ...4 34 Section 4 Parts This page intentionally left blank...

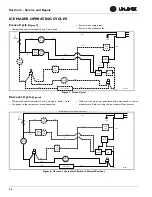

Страница 63: ...5 2 Section 5 Wiring Diagrams U CO29A CO1175A BI2115 ADA15IM 115 VOLT ULN 29R 115 VOLT...

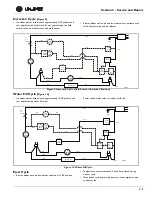

Страница 64: ...5 3 Section 5 Wiring Diagrams 1075BEV 1075WC 115 VOLT...

Страница 65: ...5 4 Section 5 Wiring Diagrams ULN 95 ULN 98 SP18 22 1095 220 VOLT CO 29A CO1175 BI2115 ADA15IM 220 VOLT...