DL200X operating manual for external sensors

4

EN

5.2. Note at initial startup

b

After starting the device for the first time, the message “SET TIME”

appears on the display. However, no settings need to be made directly

on the device. The time synchronises itself with the PC time automatically when

connected to the SmartGraph software for the first time.

6. Operation

The PC software SmartGraph is the central configuration interface for your data

logger. All additional configuration and visualisation specifications can only be

set by software.

Basic settings can be directly configured with one-button operation by using

the mode selection button on your data logger.

You can restrict the one-button operation with the mode selection button from

your software if necessary (key lock). It is not possible to operate your data

logger with the mode selection button in this case.

6.1. Switching on and off

When current is being supplied, the data logger cannot completely switch off,

but can only be set to an operating mode with minimal energy consumption

(M1). In this mode, measured value detection, measured value display and data

recording are inactive. An overview of the four various operating modes is pro-

vided in the next chapter.

6.2. Basic settings and operating modes

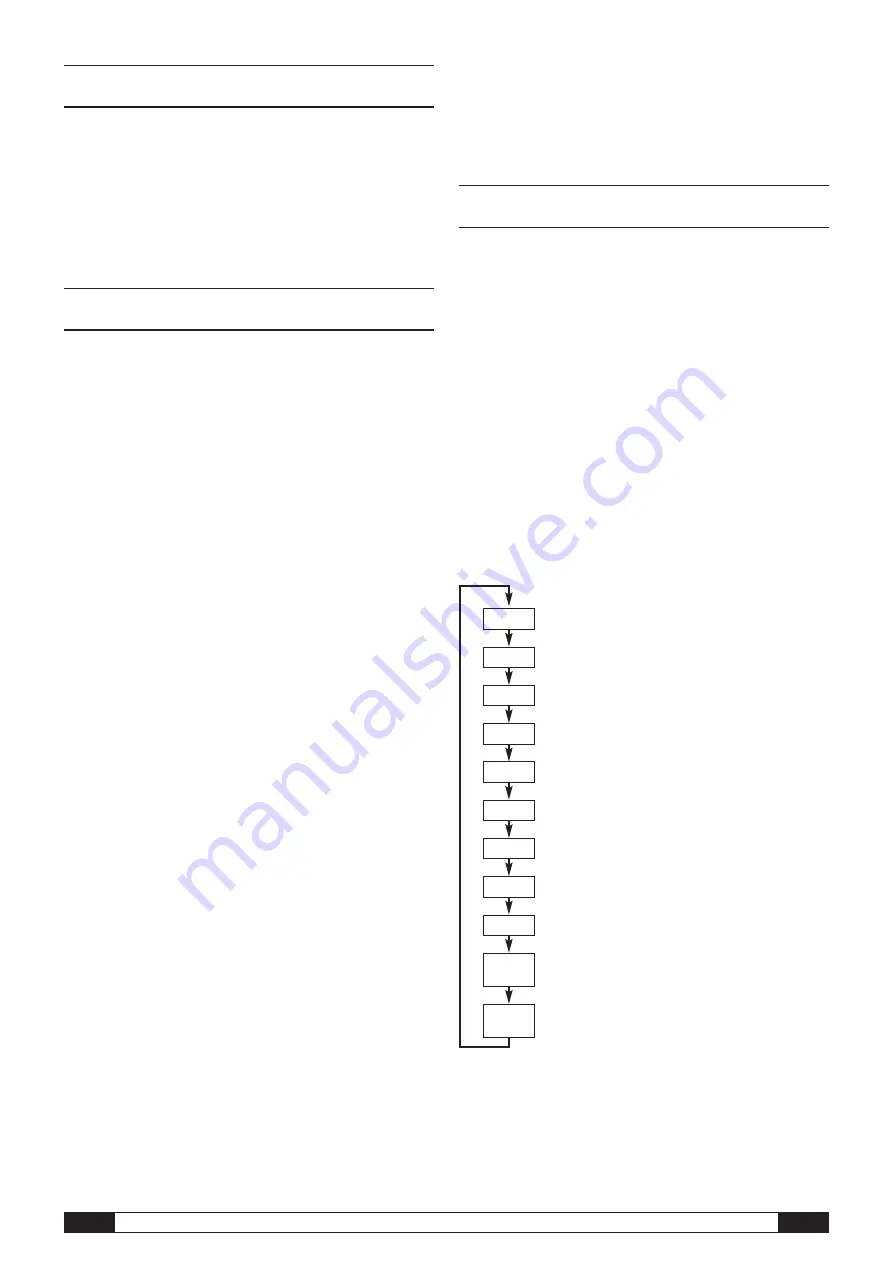

Eleven basic settings can be configured by using the mode

selection button. These include the four various operating

modes, the network function, a global reset of settings, the

acoustic function and various settings for configuring external

sensors.

Briefly pressing the mode selection button changes to the

current setting level.

Briefly pressing the mode selection button allows navigation

through the individual setting modes.

Each chosen mode is shown for four seconds and

can be selected.

Within this time, the mode marker flashes in the bottom left

corner of the display (M1, M2, M3, M4, M51, M52, M53, M6x,

M7x, M81 (An0), M81 (An1)).

Pressing the mode selection button for 1 second confirms

your selection.

The data logger then changes to the selected mode.

If no selection is confirmed within the four second period, the

setting level is left and the display returns back to the original

mode without making changes.

* This function is only available if a BUS sensor has already

been registered (M61).

M81

An 0

M1

M2

M3

M4

M51

M52

M53

M6x

M81

An 1

M7x*

4. Scope of supply

The following components are included in the standard scope of supply:

•

Data logger

•

USB connection cable

•

CD-ROM with operating manual, SmartGraph software

and software manual

•

4 x AA batteries

•

Factory certificate

5. Preparation before starting

5.1. Software

5.1.1. Installation conditions

To configure your data logger and read the recorded measured values, the

SmartGraph software must be installed on a PC with the following minimum

requirements.

Supported operating systems:

•

Windows XP from Service Pack 3 (32 bit or 64 bit version)

•

Windows Vista (32 bit or 64 bit version)

•

Windows 7 (32 bit or 64 bit version)

Hardware requirements:

•

Processor speed: 1 GHz, minimum

•

CD-ROM drive

•

USB or network connection RJ45

•

512 MB RAM, minimum

•

4 GB of free hard disk space, minimum

•

Adobe Acrobat Reader software

5.1.2. Installation of the SmartGraph software

Insert the CD-ROM into your PC drive and install the software by following the

instructions in the installation wizard.

5.1.3 Preparing data logger configuration

If necessary, connect the external sensors which are needed for detecting

measured values to the external connections of your data logger.

Information about connecting and configuring suitable sensors is provided

in chapters 7 and 11. Follow the instructions in chapter 7 for connecting ex-

ternal sensors and then continue with startup.

Afterwards, connect the data logger to your PC via the USB cable provided in

the scope of supply. The measuring device is automatically detected by the

SmartGraph software.

Alternatively, you can configure your data logger via a LAN connection over

your local network if the network function is enabled. Further information about

the network function is provided in chapter 6.2.2.

Start the SmartGraph software. The program automatically detects the connected

data logger and adds it to the list of available data loggers. The data logger can

now be configured via the software.

Further detailed information about using the software is provided in the

software manual which you can open from the help function of the Smart-

Graph software.