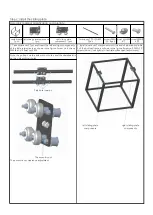

Aluminum2

PM4*20

2-M3Hole on the lateral

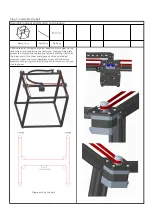

2. Will the Z axis of the carriage motor board ship nut to adjust, and put the

Z axis carriage in graphical position within the aluminum 2, here is a hole

on the outside of the M3 will be polished rod with aluminum 2 hole

alignment, with 20 PM4 * of the aluminum 2 hole above the screw through

the component, connected to the polished rod M4 screw hole, using PM4 *

20 screws through the aluminum 2 hole under its component, connected to

the M4 screw hole position.As shown in the figure;Turn the screw rod, slide

the cross plate assembly and the bearing seat to the top, lock the four

screws PM4*20 inside the aluminum profile 2 up and down of the assembly,

then lock the boat nut on the bearing seat, and then lock the two meter

screws on the bearing seat.Turn the screw and drop the cross plate

assembly to make sure it is flexible.Otherwise, please loosen the screw and

adjust it again.Finally, lock the 4 meter screws on the coupling and the boat

nut screws on the motor board.Turn the screw again to make sure that the

board slides up and down smoothly.

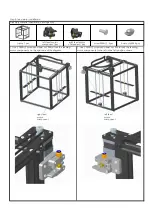

3. Repeat step 2 to assemble another z-axis slide carriage, as

shown in the figure.

Note: when the screw rod is assembled, the tail is about 3mm

inside than the polished rod.

bearing block

components

2pcs

Polished rod

Φ8*528

4pcs

screwsPM4*

20 8pcs

Lead

screwT8*453

2pcs

Step 7: assemble Z axis components

Assembly material specification and quantity:

beam

component

2pcs

frame 1pcs

Z axis motor bracket 2pcs

1. Take 1 piece of motor bracket of Z axis, insert the polished rod

into the acrylic plate hole of the motor bracket, and do not

protrude, as shown in the figure. Then, insert the cross plate

components into the second polished rod, and connect the screw

rod through the screw nut to the coupling hole of the

motor.Assemble a total of 2 sets --Z axis sliding rack.

3mm

Содержание X5S 2E

Страница 16: ...Wiring diagram of main board ...