QSH4218 Manual (V1.03 /13-November-2007)

10

Copyright © 2007, TRINAMIC Motion Control GmbH & Co. KG

5.3 Motor Driver Supply Voltage

The driver supply voltage in many applications can not be chosen freely, because other components

have a fixed supply voltage of e.g. 24V DC. If you have to possibility to choose the driver supply

voltage, please refer to the driver data sheet, and consider that a higher voltage means a higher

torque at higher velocity. The motor torque diagrams are measured for a given supply voltage. You

typically can scale the velocity axis (steps / sec) proportionally to the supply voltage to adapt the

curve, e.g. if the curve is measured for 48V and you consider operation at 24V, half all values on the

x-Axis to get an idea of the motor performance.

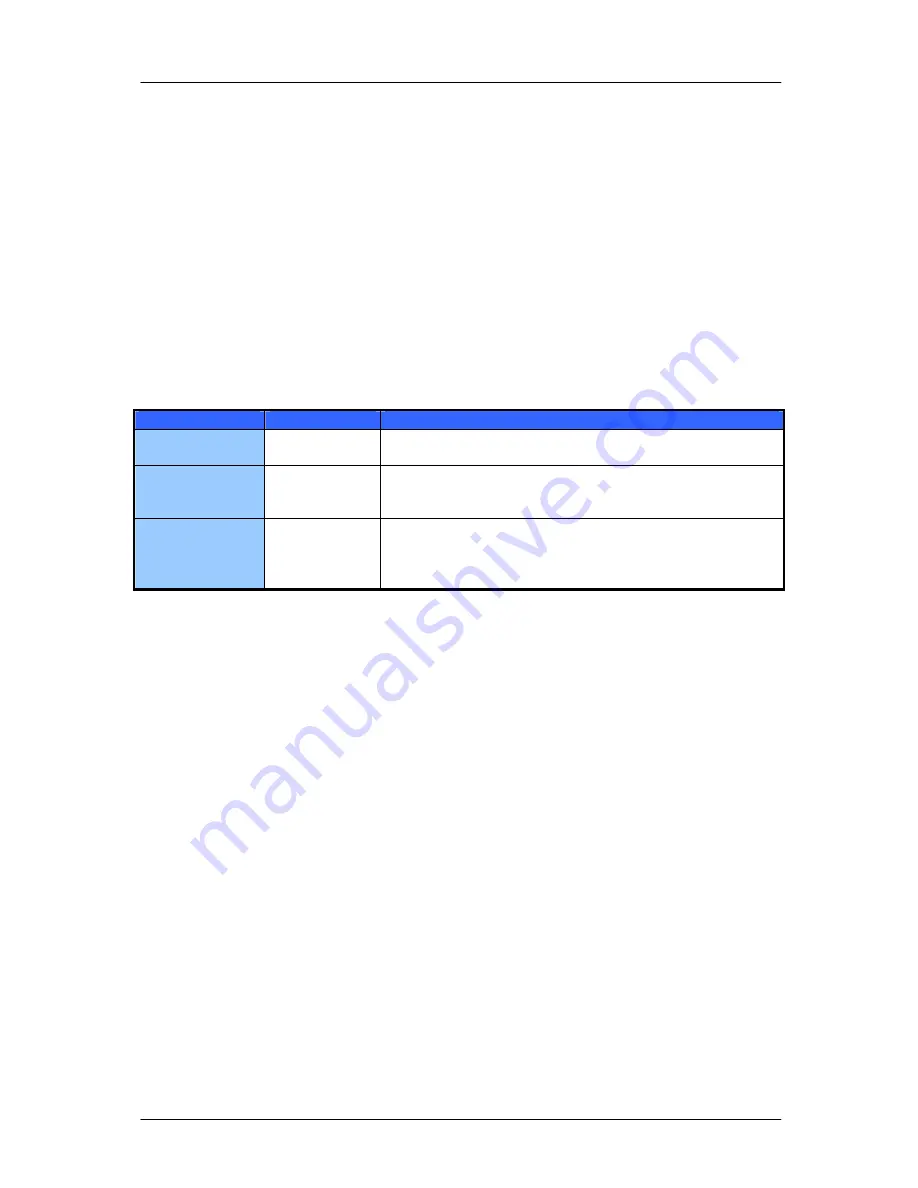

For a chopper driver, consider the following corner values for the driver supply voltage (motor

voltage). The table is based on the nominal motor voltage, which normally just has a theoretical

background in order to determine the resistive loss in the motor.

Comment on the nominal motor voltage:

U

COIL_NOM

= I

RMS_RATED

* R

COIL

(Please refer to motor technical data table.)

Parameter

Value

Comment

Minimum driver

supply voltage

2 * U

COIL_NOM

Very limited motor velocity. Only slow movement without

torque reduction. Chopper noise might become audible.

Optimum driver

supply voltage

≥

4 * U

COIL_NOM

and

≤

22 * U

COIL_NOM

Choose the best fitting voltage in this range using the motor

torque curve and the driver data. You can scale the torque

curve proportionally to the actual driver supply voltage.

Maximum rated

driver supply

voltage

25 * U

COIL_NOM

When

exceeding this value, the magnetic switching losses in

the motor reach a relevant magnitude and the motor might

get too hot at nominal current. Thus there is no benefit in

further raising the voltage.

Table 5.2: Driver supply voltage considerations

Hints:

Q: How to determine if the given driver voltage is sufficient?

A1:

Just listen to the motor at different velocities. Does the “sound” of the motor get raucous or

harsh when exceeding some velocity? Then the motor gets into a resonance area. The reason is,

that the motor back-EMF voltage reaches the supply voltage. Thus, the driver can not bring the full

current into the motor any more. This is typically a sign, that the motor velocity should not be

further increased, because resonances and reduced current affect motor torque.

A2:

Measure the motor coil current at maximum desired velocity.

For microstepping: If the waveform is still basically sinusoidal, the motor driver supply voltage is

sufficient.

For Fullstepping: If the motor current still reaches a constant plateau, the driver voltage is sufficient.

If you determine, that the voltage is not sufficient, you could either increase the voltage or reduce

the current (and thus torque).

5.4 Back EMF (BEMF)

Within SI units, the numeric value of the BEMF constant has the same numeric value as the numeric

value of the torque constant. For example, a motor with a torque constant of 1 Nm/A would have a

BEMF constant of 1V/rad/s. Turning such a motor with 1 rps (1 rps = 1 revolution per second =

6.28 rad/s) generates a BEMF voltage of 6.28V.