(

215-293-0700

7

215-293-0701

3

Technical Manual

Class B Foam System

Installation Instructions

Eductor

(

Please refer to the

Plumbing Diagram

,

Figure 4

on

Page 6

)

Mount the eductor in a 2"

[50 mm]

diameter line from the discharge side of the fire pump with a 2"

[50 mm]

ball shut-off valve upstream

of the eductor. The discharge side of the eductor is plumbed with 2"

[50 mm]

piping back to the suction side of the fire pump. Observe

the flow direction arrow on the eductor for proper placement.

Foam Concentrate Metering Valve

A 2" metering valve can be mounted to an enclosed pump panel or directly into the piping with access to the pump operator. If mounted

to an enclosed pump panel, piping connections to the valve must be properly supported – see valve mounting hole pattern

Figure 3

on

Page 5

. Supply the inlet side of the metering valve with 2"

[50 mm]

plumbing from the foam concentrate tank. This line

must include a 2"

[50 mm]

foam tank ball shut-off valve. 2"

[50 mm]

plumbing connects the discharge side of the metering valve to the

eductor. Details of the metering valve internals are shown

Figure 5

on

Page 9

.

This Line Must Include a 2"

[50 mm]

Check Valve (supplied

with the kit) to prevent back flow of water to the foam concentrate tank.

NOTE

: The swing check valve must be mounted in a horizontal position and in the correct direction for proper operation.

External Foam Concentrate Connection

A 2"

[50 mm]

valved hose connection can be provided at the pump panel to allow an external foam concentrate supply from drums, pails,

etc. See

Page 7

for optional auxiliary foam concentrate pickup hose and pickup tubes.

Flushing Piping

Piping of 2"

[50 mm]

diameter is to be installed between the water inlet connection of

the eductor and foam concentrate inlet of the metering valve as a means to flush both

the metering valve and eductor after each use. This plumbing must include a 2"

[50

mm]

ball shut-off valve.

Schematic/Instruction Chart

A backing plate is supplied for the schematic/instruction plate and must be mounted in

close proximity to the foam metering valve.

Refer to

Figure 2

on

Page 5

for the mounting hole dimensions.

Plumbing Requirements

NOTE

: The design of the Metering Valve and Eductor are not intended to support

the weight of the 2"

[50 mm]

plumbing. Piping to and from the Eductor and Foam

Metering Valve must be properly supported.

Foam metering valve and all of the 2"

[50 mm]

ball shut-off valves in the system

must be accessible to the pump operator.

Refer to

Figure 3

on

Page 5

for the mounting hole dimensions for the

Metering

Valve

Backing Plate

.

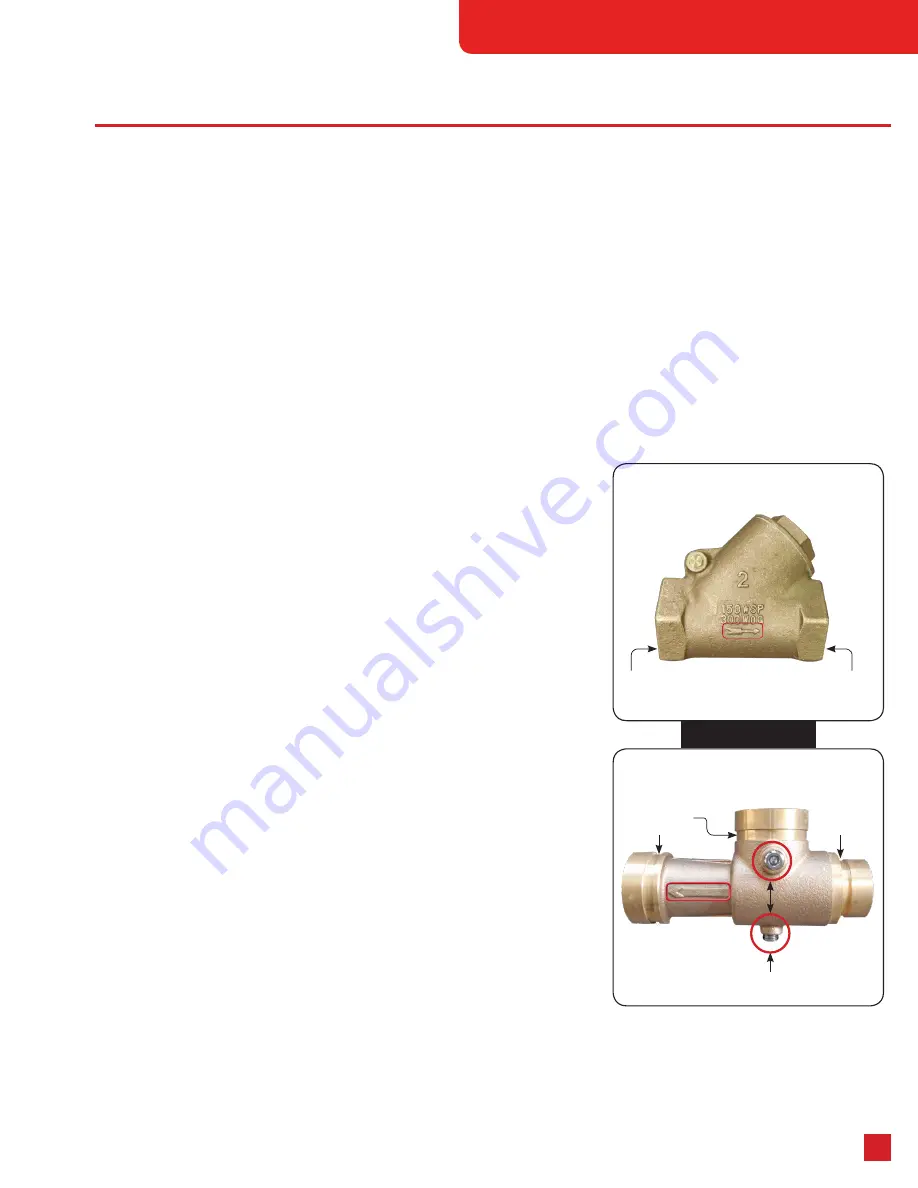

Observe that the cast in arrows in the red rectangles in

Figure 1

on the Check

Valve and Eductor are installed in the manner as shown in the plumbing diagram

Figure 4

on

Page 6

.

The eductor features two (2)

1

⁄

4

" NPT pipe plugs shown in the red circles in

Figure

1

for use as drain points based on the orientation of the eductor. All other plumbing

connections on the eductor are VIC pipe grooved ends.

Plumbing Recommendations

(Also Refer to top of

Page 7

)

Install a valved direct water tank fill line to keep the on-board water tank filled

from hydrant or nurse tanker. With this feature the foam system can be used

continuously from the on-board water tank greatly simplifying the 5 PSI inlet pump

pressure restriction.

Install a valved external auxiliary foam inlet connection at the pump panel to

supplement the on-board foam tank. With this feature, using a pick-up tube, a different type of foam concentrate can be used from

that of the on-board tank. It also eliminates the need to fill the on board foam cell during an extended operation by supplying foam

concentrate directly from containers on the ground. Also, with this auxiliary foam inlet and pick-up tube, foam system training

can be done simply utilizing a container on the ground filled with water; operators can see how the system draws water based on

different metering valve settings.

▲

Figure 1

▼

2" FNPT

[50 mm]

2" VIC

[50 mm]

1

1

⁄

2

" VIC

[38 mm]

1

⁄

4

" NPT

[7.1mm]

2" FNPT

[50 mm]