24

TRI TOOL INC.

92-1783 Orig. 161006

10.3 LUBRICANT ReCOMMeNDATIONs

•

The drive gears require a high string lubrication grease such as ‘Chevron

Ultra-Duty Grease EP NLGI2 (P/N 68-0024).

•

The air motor requires a Class 2 lubricant, viscosity of 100 to 200 SSU at

100° F (38° C) minimum aniline point of 200° F (93° C).

TRI TOOL INC. Air Tool Lubricant (P/N 68-0022)

AMOCO – American Industrial Oil No. 32

Atlantic Richfield – Duro Oil S-150

Chevron – A.W. Machine Oil 32

Exxon – Nuto H32

Shell – Tellus Oil 32

• The bearings in the air or electric motor which are sealed, do not require

lubrication.

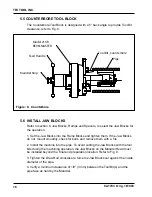

10.4 TIgHTeNINg THe fRONT BUsHINg

(Refer to illustration on next page.)

Tighten the Tapered Split Bushing when the Mandrel Shaft is loose by doing

the following:

1. Rotate the Feed Handle to extend the Mandrel outward to the limit.

2. Remove the tool modules from the headstock to provide room to use the

spanner wrench.

3.

Loosen the two flat head screws in the RETAINING PLATE on the front of the

headstock.

4. Tighten the retaining plate on the front of the center feed housing.

5.

5. Tighten the two flat head screws in the lock nut.

Содержание BEVELMASTER 216B

Страница 1: ...92 1783 Orig 161006 Model 216B BEVELMASTER ...

Страница 31: ...29 Model 216B BEVELMASTER 92 1783 Orig 161006 Page intentionally left blank ...

Страница 53: ......