6

Section 3. Unit Preparation

3.1 Prepare The Unit For Installation

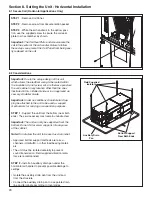

STEP 1 - Check for damage and report promptly to

the carrier any damage found to the unit.

Note:

The unit is shipped “upside-down” in the

downflow orientation and may be easiest to trans-

port to the job site in that orientation. If the unit

must be transported in a horizontal position, it must

be laid on its back (marked “REAR” on carton).

Note:

After the unit is removed from the carton,

depress the Schrader valve to verify coil is pressur-

ized.

3.2 Unit Accessories

Accessory Number

Description

Fits Cabinet Size

BAYEAAC05BK1A

Electric Heater, 5kW, Breaker, 24V Control, 1 Ph

A to C

BAYEAAC05LG1A

Electric Heater, 5kW, Lugs, 24V Control, 1 Ph

A to C

BAYEAAC08BK1A

Electric Heater, 8kW, Breaker, 24V Control, 1 Ph

A to C

BAYEAAC08LG1A

Electric Heater, 8kW, Lugs, 24V Control, 1 Ph

A to C

BAYEAAC10BK1A

Electric Heater, 10kW, Breaker, 24V Control, 1 Ph

A to C

BAYEAAC10LG1A

Electric Heater, 10kW, Lugs, 24V Control, 1 Ph

A to C

BAYEABC15BK1A

Electric Heater, 15kW, Breaker, 24V Control, 1 Ph

B to C

BAYEABC20BK1A

Electric Heater, 20kW, Breaker, 24V Control, 1 Ph

B to C

BAYEACC25BK1A

Electric Heater, 25kW, Breaker, 24V Control, 1 Ph

C

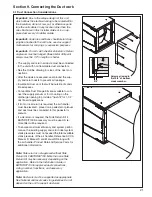

BAYSUPFLGA

Supply Duct Flange A

A

BAYSUPFLGBA

Supply Duct Flange B

B

BAYSUPFLGCA

Supply Duct Flange C

C

BAYRETFLGAA

Return Duct Flange A

A

BAYRETFLGB

Return Duct Flange B

B

BAYRETFLGCA

Return Duct Flange C

C

TASB175

Plenum Stand A

A

TASB215

Plenum Stand B

B

TASB235

Plenum Stand C

C

BAYSRKIT100A

Side Return Kit

A to C

BAYICSKIT01A

Internal Condensate Switch Kit

A to C

BAYHHKIT001A

Horizontal Hanger Kit

A to C

BAYUVCLK001A

UVC Lights

A to C

BAYLVKIT100A

Low Voltage Conduit Entry Kit

A to C

Table 3.2