32

AFDG-SVU01L-EN

Service Interface

AFD Operator Interface

Chiller information is tailored to operators, service

technicians, and owners. When operating a chiller, there is

specific information you need on a day-to-day basis—

setpoints, limits, alarm information, and reports.

When servicing a chiller, you need different information

and usually more of it—historic and active alarms,

configuration settings, and customizable control

algorithms, as well as operation settings.

By providing two different tools—one for daily operation

and one for periodic service—everyone has easy access to

pertinent and appropriate information.

Tracer AdaptiView Operator Interface

For the operator’s day-to-day operational information,

Tracer® AdaptiView™ displays data (English or SI units)

simultaneously on the 12-inch, color touch-sensitive

screen. Logically organized groups of information—chiller

modes of operation, active alarms, settings and reports

put information conveniently at your fingertips. The AFD

status can be viewed from the Tracer® AdaptiView™

MOTOR target area on the home page. Refer to the

Tracer

AdaptiView Display for CenTraVac Chillers, Daily

Operations

manual (CTV-SVU01*-EN) for more

information on the Tracer® AdaptiView™ display.

Tracer TU Service Tool (Laptop Computer)

Tracer® TU is software installed on a portable laptop

computer and used, by the service technician or advanced

operator, to interface with the UC800 controller on the

CenTraVac™ chiller. When you need more detailed

information about a Trane® chiller, connect your laptop

computer (with the Tracer® TU software installed) to the

UC800’s “Service Tool” USB plug-in port (this port is

extended to exterior of the control panel cabinet for easy

access).

The Tracer® TU software provides access to that particular

machine’s configuration settings, customizable limits,

status, and up to 60 active or historic alarms. A technician

can interact with an individual device or a group of devices

for advanced troubleshooting. For more information on

Tracer® TU, visit your local Trane Service company, or

Trane‘s website at

.

Use Tracer® TU when a factory or startup setting requires

field alterations.

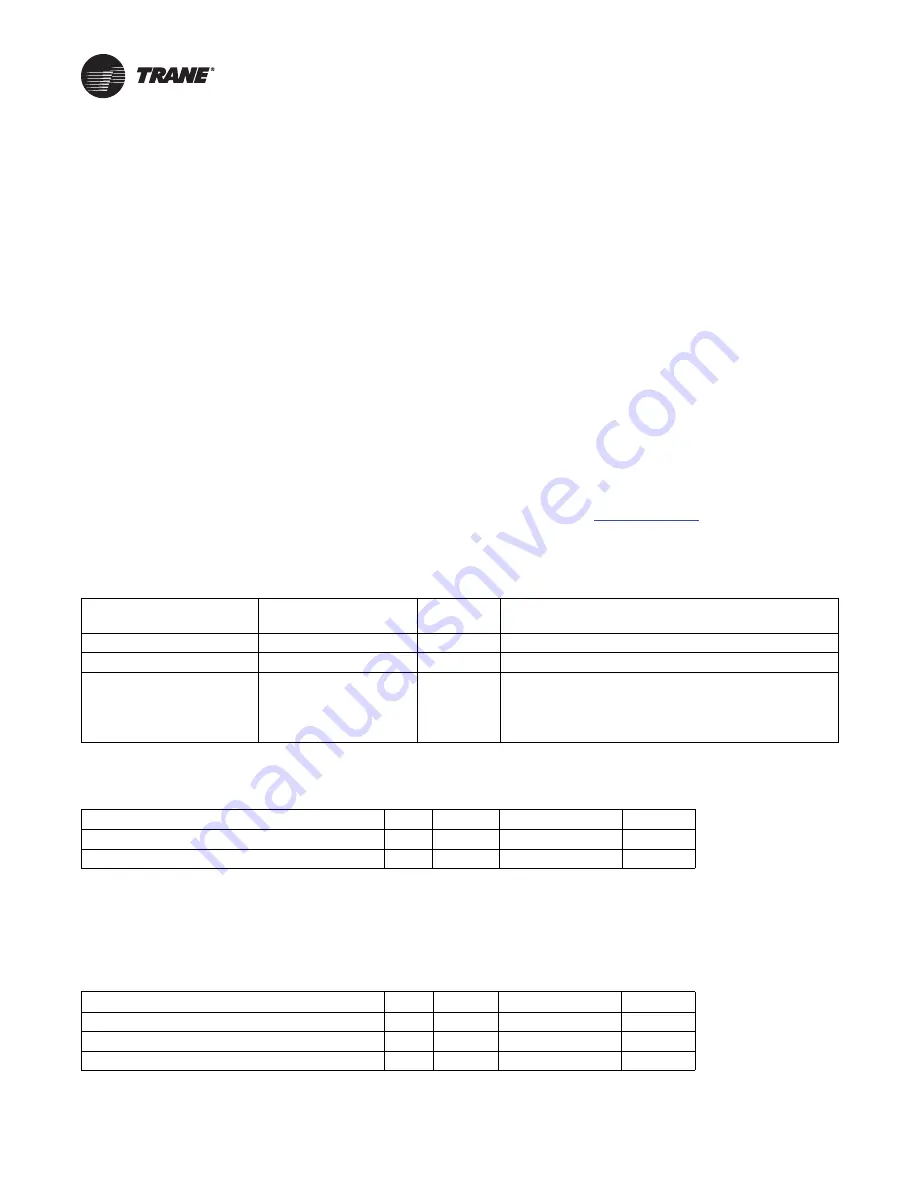

Table 5.

The following Adaptive Frequency Drive (AFD) information is available from the Tracer AdaptiView display:

Tracer® AdaptiView™

Display

MENU items

Units

Comments

Reports - Motor (AFD items)

AFD Frequency

Hz

Settings - Mode Overrides

Oil Pump Manual Control

Auto/On

Oil pump manual control

Chiller Control Signal

Auto/Manual

Manual control allows the user to override the automatic signal

and manually drive the Compressor Control Signal from 0–100%.

The limits and safeties remain active. The compressor control

signal controls a calculated combination vanes position and drive

speed for leaving water control signal.

Note:

Both motor report and mode overrides contain chiller content along with the AFD related items identified above.

Table 6.

Tracer TU: Service Setpoints view: Adjustable Frequency Drive Setpoints section

Description

Min

Max

Factory Default

Units

AF Control

N/A

N/A

(Auto, Fixed)

Auto

N/A

Re-Optimization Sensitivity

0

100

20%

Percent

Notes:

1.

Use only Factory Defaults. Defaults other than above may effect chiller reliability

2. AF Re-optimization Sensitivity

- Every 30 minutes the optimizing algorithm compares the current value of the inlet

guide vane position to the value that was stored after the last re-optimization. If the difference is greater than the AF Re

optimization Sensitivity setting, re-optimization occurs. This value is adjustable from 0 to 100%, where 0 would

guarantee re-optimization every 30 minutes and 100% would guarantee no re-optimization.

Table 7.

Tracer TU: Field Startup view: Adjustable Frequency Drive section

Description

Min

Max

Factory Default

Units

Maximum Frequency

38

60

60

Hertz (Hz)

Minimum Frequency

38

60

38

Hertz (Hz)

AFD Surge Capacity Increase

0

5

1

Hertz (Hz)