9

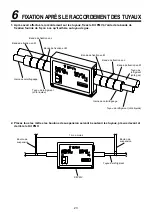

Airtight test/Air purge, etc.

For airtight test, air purge, addition of refrigerant, and gas leak check, follow the Installation Manual attached to the

outdoor unit.

REQUIREMENT

Be sure to use the tool such as charge hose exclusive to R410A.

Do not turn on the power until the airtight test and the vacuuming have finished.

(If turning on the power, the incorporated PMV is closed fully and the period until the vacuuming finishes

elongates.)

Open fully valves of the outdoor unit

Gas leak check

Check with a leak detector or soap water whether gas leaks or not, from the pipe connecting section or cap of the

valve.

REQUIREMENT

Use a leak detector manufactured exclusively for HFC refrigerant (R410A, R134a, etc.).

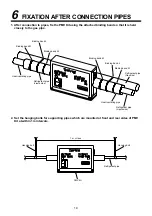

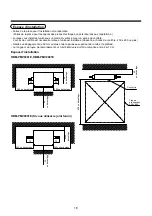

Heat insulating process

Perform heat insulating for pipes at liquid side and gas

side separately.

In cooling time, temperature at both liquid and gas

sides becomes lower.

Therefore, perform heat insulating process sufficiently

to avoid dewing.

• For heat insulator of pipe at gas side, be sure to use

one with heat-resisting temp. 120°C or more.

• Using the attached heat insulating pipe, perform heat

insulating process securely for pipe connecting part

of the PMV Kit without clearance.

REQUIREMENT

Apply the heat insulation to the pipe connecting section of the PMV Kit securely up to the root without exposure

of the pipe. (The pipe exposed to the outside causes water leak.)

5

REFRIGERANT PIPING

PMV Kit

Union

Flare nut

Heat insulating pipe

(Attached)

Binding band

(Attached)

Heat insulator