22

Checking for Bent Blades

1. Stop the engine, set the parking brake, remove the key,

and disconnect the spark plug wire(s) from the spark

plug(s).

2. Rotate the blades until the ends face forward and

backward (Fig. 19). Measure from a level surface to the

cutting edge of the blades (Fig. 20). Note this

dimension.

F ront

m–1078

Figure 19

MEASURE

FROM

CUTTING EDGE TO A

LEVEL SURFACE

m–2539

Figure 20

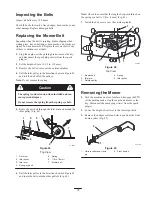

3. Rotate the opposite ends of the blades forward. Measure

from a level surface to the cutting edge of the blades at

the same position as in step 2 above. The difference

between the dimensions obtained in steps 2 and 3 must

not exceed 1/8 in. (3 mm). If this dimension exceeds

1/8 in. (3 mm), the blade is bent and must be replaced;

refer to Removing the Blades and Installing the Blades,

page 23.

A blade that is bent or damaged could break apart

and could seriously injure or kill you or

bystanders.

•

Always replace bent or damaged blade with a

new blade.

•

Never file or create sharp notches in the edges

or surfaces of blade.

Warning

Removing the Blades

The blades must be replaced if a solid object is hit, if the

blade is out of balance, or the blade is bent. To ensure

optimum performance and continued safety conformance of

the machine, use genuine Toro replacement blades.

Replacement blades made by other manufacturers may

result in non-conformance with safety standards.

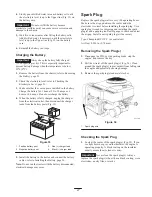

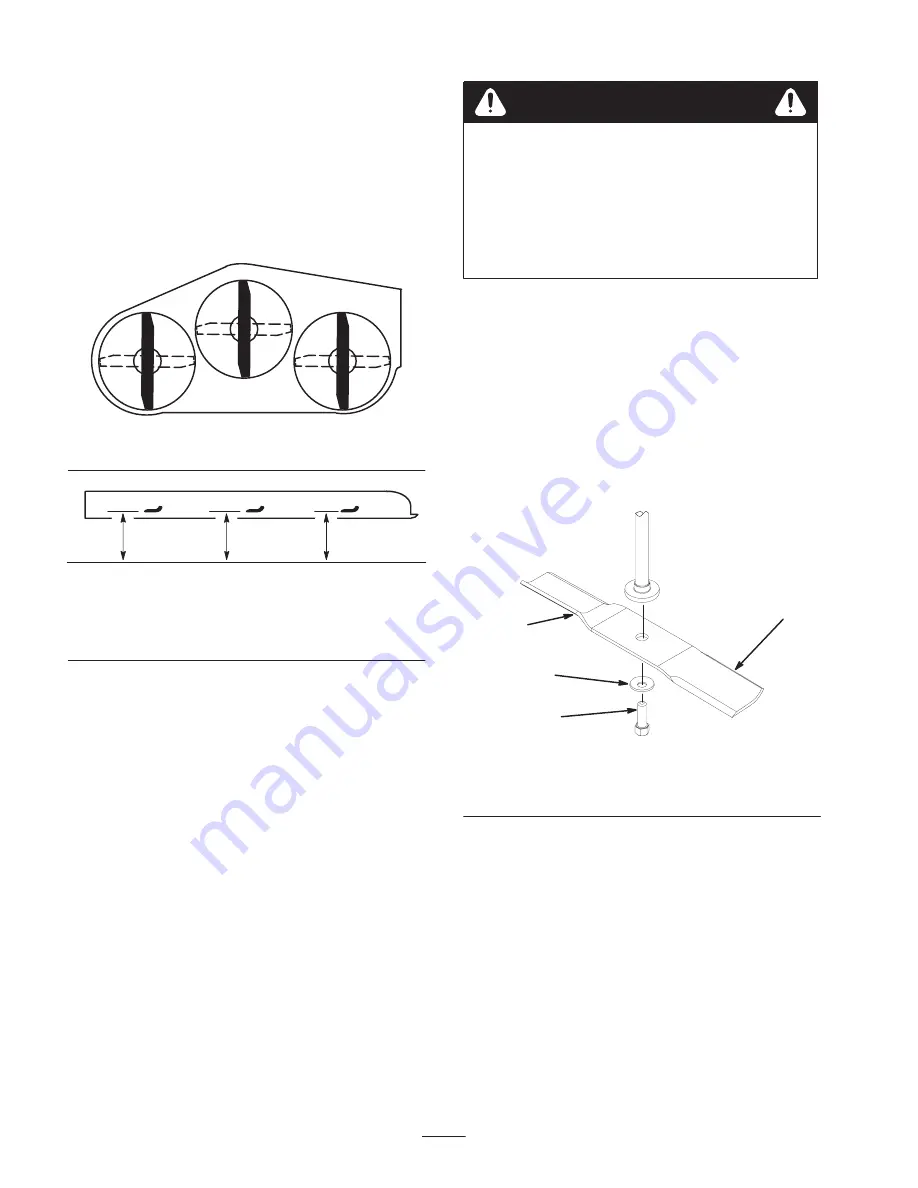

Hold the blade end using a rag or thickly-padded glove.

Remove the blade bolt, curved washer, and blade from the

spindle shaft (Fig. 21).

1

3

2

4

m–5160

Figure 21

1.

Sail area of blade

2.

Blade

3.

Curved washer

4.

Blade bolt

Содержание Z16-44 TimeCutter

Страница 6: ...6 ...

Страница 7: ...7 Slope Chart ...

Страница 8: ...8 ...

Страница 11: ...11 104 8014 1 Parking brake 104 5091 104 8088 ...

Страница 38: ...38 ...

Страница 39: ...39 ...