57

GTS 200

Cylinder and Bearings

Check Plain or DU

Bearings

Bearings should be replaced if scored or if plug gauge will

enter. Try gauge at several locations in bearing, Fig. 140.

1

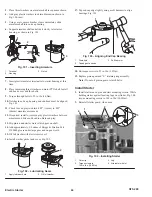

Fig. 140 – Checking Bearing

1.

Plug gauge

See gauge listing in Table No. 1, page 57, Magneto Bearings,

or Table No. 2, page 57, PTO Bearings.

If gauge is not available, refer to Table No. 5, page 58 for

reject dimensions.

Scored or damaged DU

magneto bearings can be replaced,

Table No. 1, page 57.

Check Camshaft Bearings

Replace cylinder, crankcase cover, or sump if cam gear

bearings are worn more than than shown in Table No. 6,

page 58. If specified plug gauge can be inserted in bearing

1/4” (6.35mm) or more, replace cylinder, crankcase cover or

sump, Fig. 141. If gauge is not available, and bearings are

worn larger than dimensions shown in Table No. 6, replace

cylinder, crankcase cover or sump.

Fig. 141 – Checking Camshaft Bearing

Plain or DU

Bearings

Repair Worn Aluminum Bearings

Select tools needed to repair magneto bearing from

Table No. 1. Remove and discard oil seal for bearing to be

repaired. Place pilot guide bushing in bearing opposite of

bearing to be repaired. Have flange of bushing on inside of

crankcase. Replace sump if sump crankshaft bearing is worn

or damaged.

Table No. 1

Magneto Bearing Repair Tool Chart

Briggs & Stratton Tools

Cylinder

Support

Bushing

Driver

Plug

Gauge

19123

19124

19166

Table No. 2

PTO Bearing Repair Tool Chart

Cylinder

Support

Bushing

Driver

Plug

Gauge

N/A

N/A

19375

Remove DU

Magneto Bearing

1. Refer to Table No. 1, page 57, for tools required to remove

DU

bearings.

2. Place cylinder support under magneto bearing and place

bushing driver down through worn bearing.

3. Press bearing out of cylinder, Fig. 142.

1

ÎÎÎ

ÎÎÎ

ÏÏÏ

ÏÏÏ

ÏÏÏ

ÏÏÏÏ

ÏÏÏÏ

ÏÏÏÏ

3

2

Fig. 142 – Removing Bearing

1.

Bushing driver bearing

2.

Bearing

3.

Cylinder support

Install Magneto DU

Bushing

1. Place DU bearing on cylinder or cover bearing with oil

hole in line with oil hole in cylinder or cover bearing. If

cover bearing does not have oil hole, place split (when

present) of bearing as shown in Fig. 143.

1

Fig. 143 – Locating and Staking Bearing

1.

Split in bearing