Greensmaster 3320/3420

Hydraulic System

Page 5 -- 17

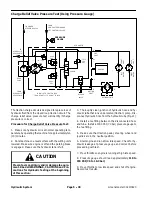

Raise Cutting Units

The gear pump is directly coupled to the piston (traction)

pump. The gear pump supplies hydraulic flow for the

steering circuit (priority flow), for raising and lowering

the cutting units and for the traction charge circuit. The

gear pump takes its suction from the hydraulic reservoir.

Maximum circuit pressure of 1160 PSI (80 bar) is limited

by the relief valve located in the power steering valve.

The lift control manifold includes four (4) electrically op-

erated solenoid valves. Solenoid valve S1 causes circuit

flow to by--pass the lift cylinders when de--energized

and directs flow to the cylinders when energized. Direc-

tional solenoid valve S2 is used to direct oil flow to raise

the cutting units when de--energized and lower them

when energized. When energized, solenoid valve S3 al-

lows hydraulic flow to and from the front cutting unit lift

cylinders (#2 and #3) and prevents oil passage to and

from the lift cylinders when de--energized. When ener-

gized, solenoid valve S4 allows hydraulic flow to and

from the center cutting unit lift cylinder (#1) and prevents

oil passage to and from the lift cylinder when de--ener-

gized.

The console arm joystick is used to raise and lower the

cutting units. The joystick acts as an input to the TEC

controller to send electrical outputs to appropriate lift

control manifold solenoid coils in order to raise or lower

the cutting units.

While operating the machine during conditions of not

raising or lowering the cutting units (joystick in the neu-

tral (center) position), all of the lift manifold solenoid

valves (S1, S2, S3 and S4) are de--energized. Flow from

the gear pump is directed through the power steering

valve, de--energized solenoid valve S1 in the lift control

manifold, oil filter and to the traction charge circuit. Flow

in excess of charge circuit needs then returns to the gear

pump input.

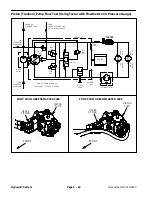

Raise Cutting Units

When the joystick is moved to the raise position, the Toro

Electronic Controller (TEC) energizes lift control man-

ifold solenoid valves S1, S3 and S4 for approximately

three (3) seconds. This time frame ensures that the cut-

ting units will be fully raised. The controller provides a

short delay in energizing solenoid valve S4 which delays

the raising of the center cutting unit (#1).

Energized lift manifold solenoids S1, S3 (front lift cylin-

ders) and S4 (center lift cylinder) direct circuit flow to-

ward the lift cylinders in the correct direction to raise the

cutting units. The front lift cylinders retract to raise the

cutting units while the center lift cylinder extends to raise

the cutting unit. Hydraulic pressure against the lift cylin-

der pistons moves their shafts causing the cutting units

to raise. At the same time, the lift cylinder pistons push

the hydraulic fluid out of the cylinders to de--energized

solenoid valve S2. Return flow continues to the oil filter

and then to the traction charge circuit.

A 0.037 orifice (OR1) controls raising speed for the cen-

ter cutting unit (#1). Flow to the front lift cylinders (cutting

units #2 and #3) bypasses the lift manifold orifices (OR2

and OR3) when the front cutting units are being raised.

When the lift control manifold solenoid valves are de--

energized by the TEC controller, spring action returns

the valves to their original position stopping lift cylinder

movement. The lift cylinder position is locked in place

since there is no complete circuit of flow to and from the

lift cylinders. Hydraulic flow by--passes the lift cylinders

and is routed to the oil filter and charge circuit.

NOTE:

The raise function will not be allowed by the

TEC controller when the machine is in the backlap op-

eration with cutting reels engaged.

Hy

draulic

Sy

st

em

Содержание Greensmaster 3420 TriFlex

Страница 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Страница 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Страница 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Страница 14: ...0 09375 Greensmaster 3320 3420 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Страница 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Страница 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Страница 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Страница 65: ...Greensmaster 3320 3420 Hydraulic System Page 5 11 This page is intentionally blank Hydraulic System ...

Страница 113: ...Greensmaster 3320 3420 Hydraulic System Page 5 59 This page is intentionally blank Hydraulic System ...

Страница 117: ...Greensmaster 3320 3420 Hydraulic System Page 5 63 This page is intentionally blank Hydraulic System ...

Страница 123: ...Greensmaster 3320 3420 Hydraulic System Page 5 69 This page is intentionally blank Hydraulic System ...

Страница 133: ...Greensmaster 3320 3420 Hydraulic System Page 5 79 This page is intentionally blank Hydraulic System ...

Страница 137: ...Greensmaster 3320 3420 Hydraulic System Page 5 83 This page is intentionally blank Hydraulic System ...

Страница 147: ...Greensmaster 3320 3420 Hydraulic System Page 5 93 This page is intentionally blank Hydraulic System ...

Страница 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Страница 155: ...Greensmaster 3320 3420 Page 6 5 Electrical System This page is intentionally blank Electrical System ...

Страница 169: ...Greensmaster 3320 3420 Page 6 19 Electrical System This page is intentionally blank Electrical System ...

Страница 175: ...Greensmaster 3320 3420 Page 6 25 Electrical System This page is intentionally blank Electrical System ...

Страница 181: ...Greensmaster 3320 3420 Page 6 31 Electrical System This page is intentionally blank Electrical System ...

Страница 223: ...Greensmaster 3320 3420 Page 6 73 Electrical System This page is intentionally blank Electrical System ...

Страница 233: ...Greensmaster 3320 3420 Page 6 83 Electrical System This page is intentionally blank Electrical System ...

Страница 245: ...Greensmaster 3320 3420 Page 6 95 Electrical System This page is intentionally blank Electrical System ...

Страница 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Страница 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Страница 287: ...Greensmaster 3320 3420 DPA Cutting Units Page 8 9 This page is intentionally blank DPA Cutting Units ...

Страница 301: ...Greensmaster 3320 3420 DPA Cutting Units Page 8 23 This page is intentionally blank DPA Cutting Units ...

Страница 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Страница 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Страница 343: ...Page 10 5 CAN TRAK Electrical Schematic Greensmaster 3320 Serial Number Above 312000000 TO E REELS HARNESS DISPLAY ...

Страница 345: ...Page 10 7 Electrical Schematic Greensmaster 3420 Serial Number Above 312000000 DISPLAY CAN TRAK TO E REELS HARNESS ...

Страница 347: ...Page 10 9 This page is intentionally blank ...

Страница 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Страница 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Страница 360: ...Page 10 22 This page is intentionally blank ...