Greensmaster 3320/3420

Hydraulic System

Page 5 -- 73

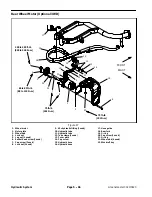

Disassembly (Fig. 50)

1. Remove the oil from the lift cylinder by slowly pump-

ing the cylinder shaft while holding the cylinder over a

drain pan. Plug both ports and clean the outside of the

cylinder.

IMPORTANT: Prevent damage when clamping the

lift cylinder in a vise; clamp on the rear mounting

flange only. Do not close vise on the barrel.

2. Mount lift cylinder in a vise. Use of a vise with soft

jaws is recommended.

3. Using a spanner wrench, rotate head clockwise until

the edge of the retaining ring (item 2) appears in the bar-

rel opening. Insert a screwdriver under the beveled

edge of the retaining ring to start the retaining ring

through the opening. Rotate the head counter--clock-

wise to remove retaining ring from barrel and head.

4. Extract shaft, head and piston assembly by carefully

twisting and pulling on the shaft.

IMPORTANT: Do not clamp vise jaws against the

shaft surface. Protect shaft surface before mount-

ing in a vise.

5. Mount shaft securely in a vise by clamping on the cle-

vis of the shaft. Remove lock nut and piston from the

shaft. Slide head off the shaft.

6. Remove wear ring, piston seal and O--ring from the

piston. Remove O--ring, back--up ring, head seal and

dust seal from the head.

CAUTION

Use eye protection such as goggles when using

compressed air to dry cylinder parts.

7. Wash lift cylinder parts in clean solvent. Dry parts

with compressed air. Do not wipe parts dry with paper

towels or cloth. Lint in a hydraulic system will cause

damage.

8. Carefully inspect internal surface of barrel for dam-

age (deep scratches, out--of--round, etc.). Inspect shaft,

head and piston for evidence of excessive scoring, pit-

ting or wear. Replace entire cylinder if internal compo-

nents are found to be worn or damaged.

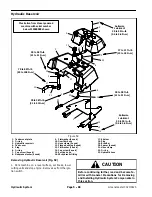

Assembly (Fig. 50)

1. Make sure all lift cylinder parts are clean before as-

sembly.

2. Coat new seal kit components with clean hydraulic

oil.

A. Install wear ring, piston seal and O--ring on the

piston.

B. Install O--ring, back--up ring, head seal and dust

seal on the head.

IMPORTANT: Do not clamp vise jaws against the

shaft surface. Protect shaft surface before mount-

ing in a vise.

3. Mount shaft securely in a vise by clamping on the cle-

vis of the shaft. Use of a vise with soft jaws is recom-

mended.

A. Coat shaft with clean hydraulic oil.

B. Carefully slide head onto the shaft.

C. Install piston and lock nut onto the shaft. Torque

lock nut from

40 ft--lb (54 N--m)

.

D. Remove shaft from the vise.

IMPORTANT: Prevent damage when clamping the

hydraulic cylinder into a vise; clamp on the rear

mounting flange only. Do not close vise on the bar-

rel.

4. Mount barrel in a vise. Use of a vise with soft jaws is

recommended.

5. Coat all internal parts with a light coat of clean hy-

draulic oil. Slide piston, shaft and head assembly into

the barrel being careful to not damage the seals.

6. Secure head in barrel by installing retaining ring.

Align retaining ring hole in the head with the access slot

in the barrel. Insert the retaining ring hook into the hole

and rotate head clockwise until the retaining ring is com-

pletely pulled into the barrel and the ring ends are cover-

ed.

Hy

draulic

Sy

st

em

Содержание Greensmaster 3420 TriFlex

Страница 2: ...Greensmaster 3320 3420 This page is intentionally blank ...

Страница 4: ...Greensmaster 3320 3420 This page is intentionally blank ...

Страница 6: ...Greensmaster 3320 3420 This page is intentionally blank ...

Страница 14: ...0 09375 Greensmaster 3320 3420 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 24: ...Greensmaster 3320 Page 3 6 Gasoline Engine This page is intentionally blank ...

Страница 38: ...Greensmaster 3420 Page 4 4 Diesel Engine This page is intentionally blank ...

Страница 54: ...Greensmaster 3420 Page 4 20 Diesel Engine This page is intentionally blank ...

Страница 56: ...Greensmaster 3320 3420 Hydraulic System Page 5 2 This page is intentionally blank ...

Страница 65: ...Greensmaster 3320 3420 Hydraulic System Page 5 11 This page is intentionally blank Hydraulic System ...

Страница 113: ...Greensmaster 3320 3420 Hydraulic System Page 5 59 This page is intentionally blank Hydraulic System ...

Страница 117: ...Greensmaster 3320 3420 Hydraulic System Page 5 63 This page is intentionally blank Hydraulic System ...

Страница 123: ...Greensmaster 3320 3420 Hydraulic System Page 5 69 This page is intentionally blank Hydraulic System ...

Страница 133: ...Greensmaster 3320 3420 Hydraulic System Page 5 79 This page is intentionally blank Hydraulic System ...

Страница 137: ...Greensmaster 3320 3420 Hydraulic System Page 5 83 This page is intentionally blank Hydraulic System ...

Страница 147: ...Greensmaster 3320 3420 Hydraulic System Page 5 93 This page is intentionally blank Hydraulic System ...

Страница 150: ...Greensmaster 3320 3420 Hydraulic System Page 5 96 This page is intentionally blank ...

Страница 155: ...Greensmaster 3320 3420 Page 6 5 Electrical System This page is intentionally blank Electrical System ...

Страница 169: ...Greensmaster 3320 3420 Page 6 19 Electrical System This page is intentionally blank Electrical System ...

Страница 175: ...Greensmaster 3320 3420 Page 6 25 Electrical System This page is intentionally blank Electrical System ...

Страница 181: ...Greensmaster 3320 3420 Page 6 31 Electrical System This page is intentionally blank Electrical System ...

Страница 223: ...Greensmaster 3320 3420 Page 6 73 Electrical System This page is intentionally blank Electrical System ...

Страница 233: ...Greensmaster 3320 3420 Page 6 83 Electrical System This page is intentionally blank Electrical System ...

Страница 245: ...Greensmaster 3320 3420 Page 6 95 Electrical System This page is intentionally blank Electrical System ...

Страница 250: ...Greensmaster 3320 3420 Page 6 100 Electrical System This page is intentionally blank ...

Страница 277: ...Greensmaster 3320 3420 Page 7 27 Chassis This page is intentionally blank Chassis ...

Страница 287: ...Greensmaster 3320 3420 DPA Cutting Units Page 8 9 This page is intentionally blank DPA Cutting Units ...

Страница 301: ...Greensmaster 3320 3420 DPA Cutting Units Page 8 23 This page is intentionally blank DPA Cutting Units ...

Страница 325: ...Greensmaster 3320 3420 Groomer Page 9 13 This page is intentionally blank Groomer ...

Страница 340: ...Greensmaster 3320 3420 Page 10 2 Foldout Drawings This page is intentionally blank ...

Страница 343: ...Page 10 5 CAN TRAK Electrical Schematic Greensmaster 3320 Serial Number Above 312000000 TO E REELS HARNESS DISPLAY ...

Страница 345: ...Page 10 7 Electrical Schematic Greensmaster 3420 Serial Number Above 312000000 DISPLAY CAN TRAK TO E REELS HARNESS ...

Страница 347: ...Page 10 9 This page is intentionally blank ...

Страница 356: ...Page 10 18 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Below 312000000 ...

Страница 358: ...Page 10 20 E Reels Wire Harness Drawing Greensmaster 3320 3420 Serial Number Above 312000000 ...

Страница 360: ...Page 10 22 This page is intentionally blank ...