3. Loosen the set screw in the adjusting knob on the

flow control.

4. If the center cutting unit is dropping too late, turn the

knob 1/4 turn counterclockwise. If the center cutting

unit is dropping too early, turn the knob 1/4 turn

clockwise.

5. After you have achieved your desired setting, tighten

the set screw.

ADJUST VALVE CLEARANCE

Initially, adjust valves after the first 50 hours of

operation, thereafter every 400 hours.

1.

Remove the breather hose and cylinder head cover

from the engine.

Note: Adjust valves when the engine is cold. Set

the No. 1 cylinder to top dead center and adjust the

clearances of intake/exhaust valves of No. 1

cylinder and exhaust valve of No. 2 cylinder. Then,

turn the crankshaft counterclockwise 240° (viewed

from front) to adjust clearance of intake valve of

No. 2 cylinder and intake/exhaust valves of No. 3

cylinder.

2.

Loosen the nut and adjust clearance of both intake

and exhaust valves to .0078" (.2mm).

3.

Install the cylinder head cover and gasket. Torque

the screws to 9–12 Nm. Install the breather hose.

TORQUE CYLINDER HEAD BOLTS

Initially, check head bolt torque after the first 50 hours of

operation, thereafter every 400 hours.

1.

Remove the breather hose and cylinder head cover

from the engine.

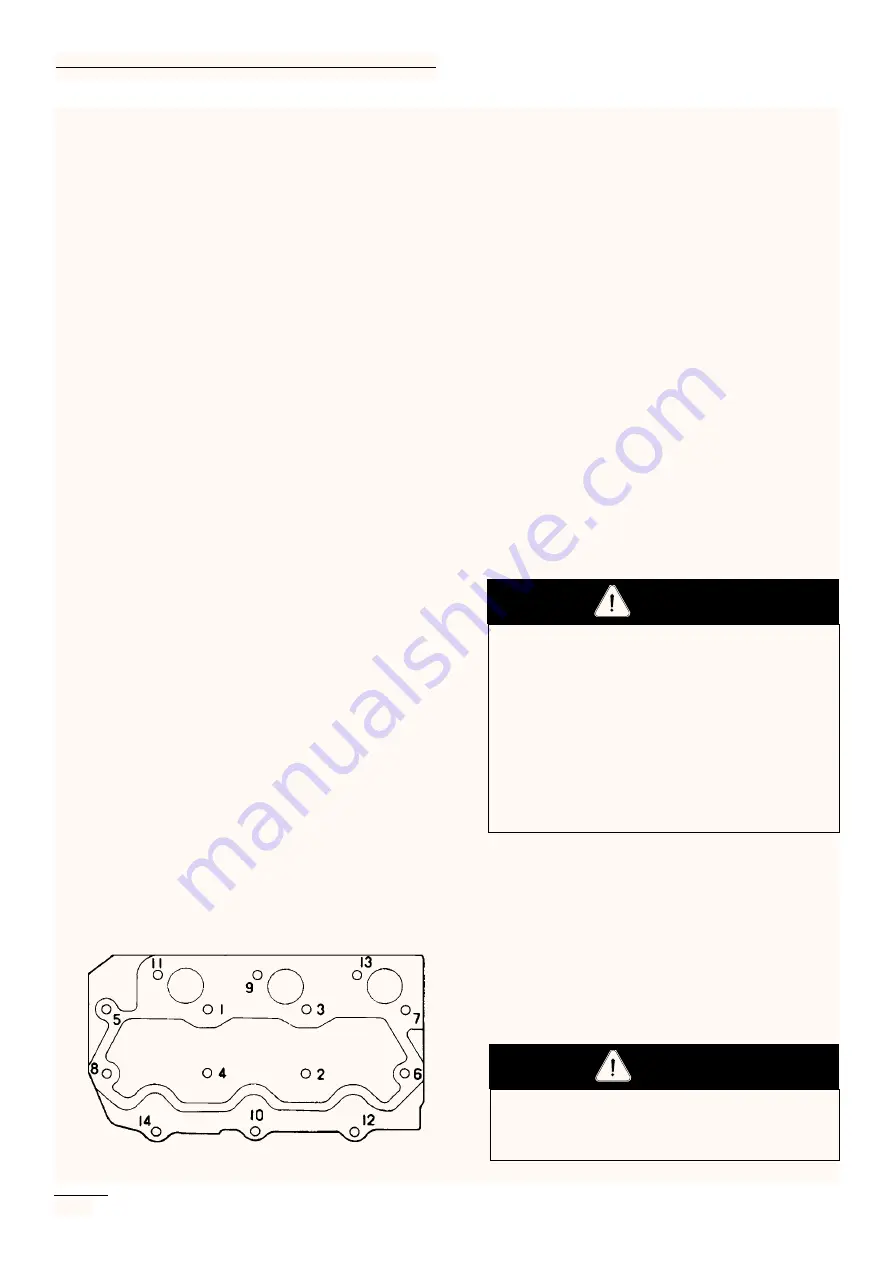

Figure 28

2.

Using the sequence in Figure 28, torque the head

bolts to 48 to 51 Nm.

3.

Install the cylinder head cover and gasket. Torque

the cover screws to 9–12 Nm. Install the breather

hose.

BATTERY CARE

1.

Battery electrolyte level must be properly

maintained and the top of the battery kept clean. if

the machine is stored in a location where

temperatures are extremely high, the battery will

run down more rapidly than if the machine is stored

in a location where temperatures are cool.

2.

Check the electrolyte level every 50 operating hours

or, if the machine is in storage, every 30 days.

3.

Maintain cell level with distilled or demineralized

water. Do not fill cells above the bottom of the split

ring inside each cell. Install the filler caps with

vents pointing to the rear (toward the fuel tank).

4.

Keep the top of battery clean by washing

periodically with a brush dipped in ammonia or

bicarbonate of soda solution. Flush the top surface

with water after cleaning. Do not remove the fill

caps while cleaning.

5.

Battery cables must be tight on the terminals to

provide good electrical contact.

28

Maintenance

Wear safety goggles and rubber gloves when

working with electrolyte. Charge the battery in a

well ventilated place so gases produced while

charging can dissipate. Since the gases are

explosive, keep open flames and electrical spark

away from the battery; do not smoke. Nausea

may result if the gases are inhaled. Unplug the

charger from the electrical outlet before

connecting to or disconnecting charger leads from

battery posts.

CAUTION

Connecting cables to the wrong post could result

in personal injury and/or damage to the electrical

system.

WARNING