Lubrication

Grease with No. 2 general purpose lithium base or

molybdenum base grease.

1.

Disengage the PTO and set the parking brake.

2.

Stop the engine, remove the key, and wait for all moving

parts to stop before leaving the operating position.

3.

Clean the grease fittings with a rag.

Note:

Make sure to scrape any paint off the front of

the fitting(s).

4.

Connect a grease gun to the fitting.

5.

Pump grease into the fittings until grease begins to

ooze out of the bearings.

6.

Wipe up any excess grease.

Lubricating the Machine

Service Interval:

Every 50 hours—Grease the lift linkage

(more often in dirty or dusty conditions).

Every 50 hours—Grease the mower deck spindles

(more often in dirty or dusty conditions).

Every 800 hours/Yearly (whichever comes

first)—Grease the front wheel bearings (more often in

dirty or dusty conditions).

Every 800 hours/Yearly (whichever comes

first)—Grease the front caster pivots (more often in

dirty or dusty conditions).

Use the following graphics for locating the grease points.

G019356

Figure 38

g026968

Figure 39

g026969

Figure 40

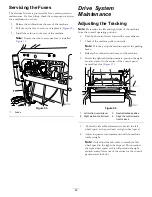

Greasing the Front Caster

Pivots

Service Interval:

Yearly

Lubricate the front caster pivots once a year.

1.

Remove the dust cap and adjust the caster pivots; refer

to

Adjusting the Caster-Pivot Bearing (page 42)

.

Note:

Keep the dust cap off until greasing is done.

2.

Remove the hex plug.

3.

Thread a grease fitting into the hole.

4.

Pump grease into the fitting until it oozes out around

the top bearing.

5.

Remove the grease fitting in the hole. Install the hex

plug and cap.

31

Содержание GrandStand 74574

Страница 65: ...g026979 Electrical Schematic Rev A 65 ...

Страница 66: ...Notes 66 ...

Страница 67: ...Notes 67 ...