Figure 8

1.

Eccentric notch

•

Tighten the bolt and nut for this eccentric to 149 N-m

(110 ft-lb).

•

Adjust the forward eccentric until it just makes contact

with the inner slot surface of the winglet pivot brackets.

•

Tighten the bolt and nut for this eccentric to 149 N-m

(110 ft-lb).

•

Repeat the procedure on the opposite winglet. Refer to

Adjusting the Cutting Unit Pitch procedure in Mower

Maintenance.

5

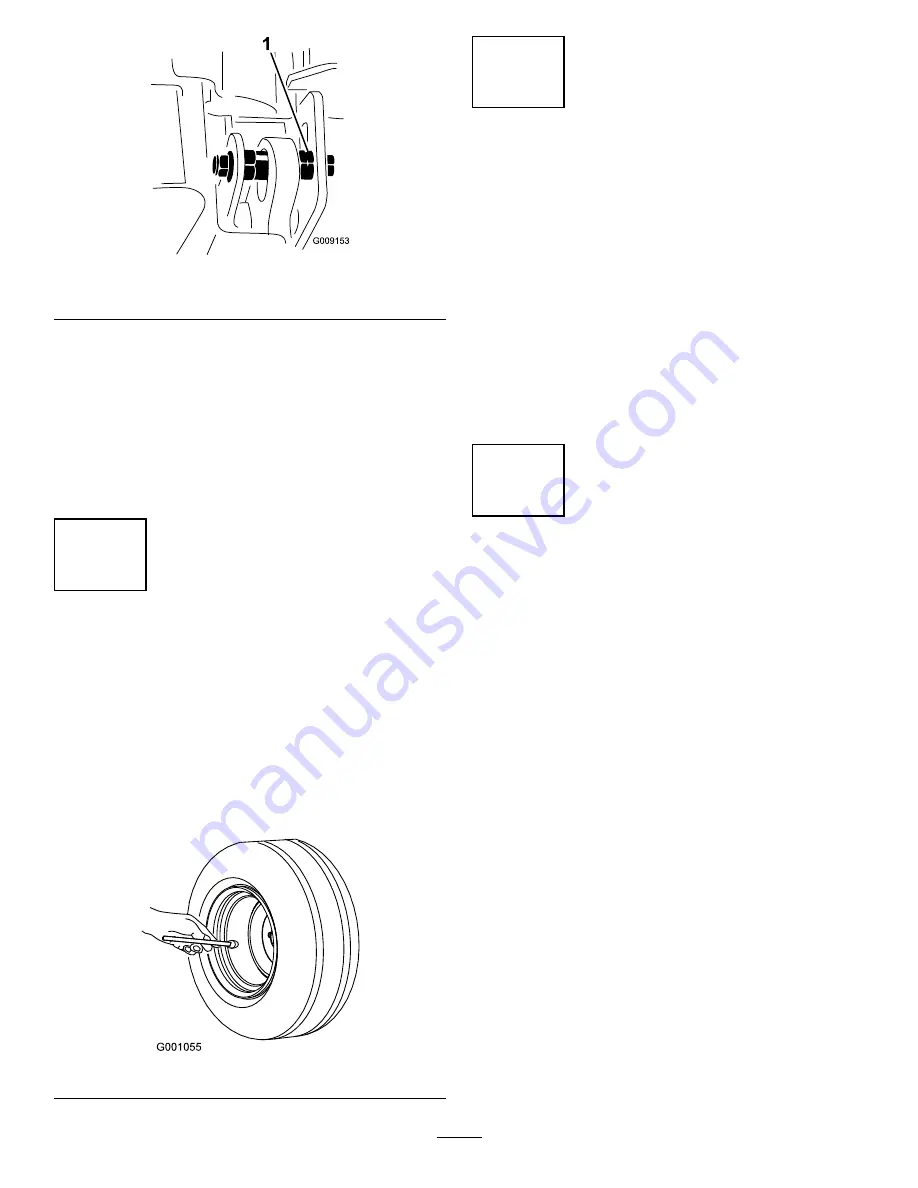

Checking the Tire Pressure

No Parts Required

Procedure

Check the air pressure in all the tires before operating the

machine. The correct air pressure in the front tires is 345 kPa

(50 psi) and the rear tires is 207 kPa (30 psi) (

).

Important:

Maintain pressure in all tires to ensure a

good quality-of-cut and proper machine performance.

Do not under-inflate.

Figure 9

6

Checking the Fluid Levels

No Parts Required

Procedure

1.

Check the engine oil level before starting the engine,

refer to Checking the Engine Oil Level in Engine

Maintenance.

2.

Check the hydraulic fluid level before starting the

engine, refer to Checking the Hydraulic Fluid Level in

Hydraulic System Maintenance.

3.

Check the cooling system before starting the engine;

refer to Checking the Cooling System in Cooling

System Maintenance.

7

Greasing the Machine

No Parts Required

Procedure

Before the machine is operated, it must be greased to

ensure proper lubricating characteristics; refer to Greasing

the Bearings and Bushings procedure in Lubrication in the

Maintenance Section. Failure to properly grease the machine

will result in premature failure of critical parts.

18