3.

Push the castor spindle through the castor arm. Install

the shims (as originally installed) and the remaining

spacers onto the spindle shaft. Install the tensioning

cap to secure the assembly.

4.

Remove the hairpin cotter and clevis pins from the

castor pivot arms (

5.

Rotate tension rod to raise or lower pivot arm until

holes are aligned with selected height-of-cut bracket

holes in the cutting unit frame (

and

6.

Insert the clevis pins and install the hairpin cotters.

7.

Rotate tension rod counterclockwise (finger tight) to

put tension on adjustment.

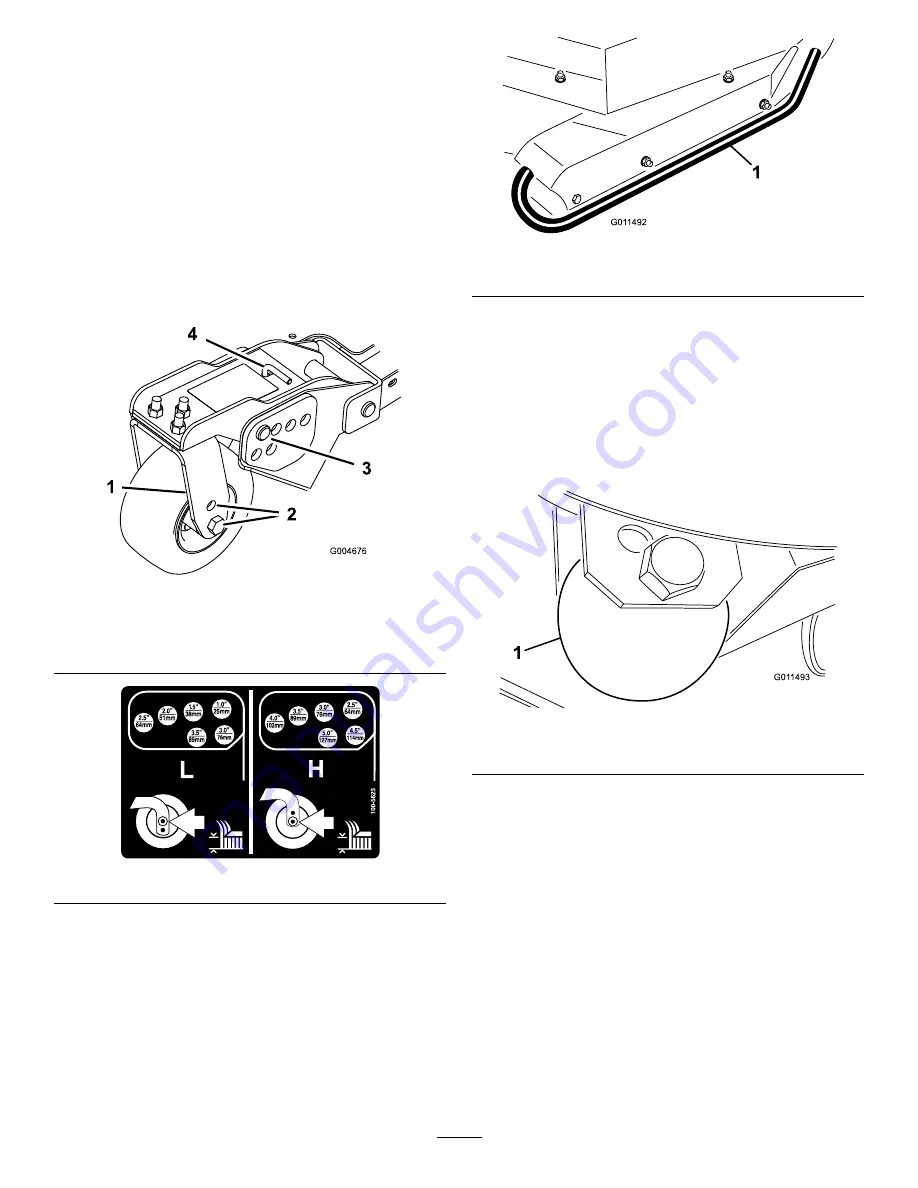

Figure 21

1.

Castor pivot arm

3.

Clevis pin and hair pin

cotter

2.

Axle mounting holes

4.

Tension rod

Figure 22

Adjusting the Skids

The skids should be mounted in the lower position when

operating at heights of cut greater than 64 mm (2-1/2 inches)

and in the higher position when operating at heights of cut

lower than 64 mm (2-1/2 inches).

Adjust the skids by removing the flange bolt and nuts,

positioning them as desired, and installing the fasteners

(Figure 24).

Figure 23

1.

Skid

Adjusting the Cutting Unit Rollers

The cutting unit rollers should be mounted in the lower

position when operating in height of cuts greater than 64 mm

(2-1/2 inches) and in the higher position when operating in

height of cuts lower than 64 mm (2-1/2 inches).

1.

Remove the bolt and nut securing the gage wheel to

the cutting unit brackets (

Figure 24

1.

Gage wheel

2.

Align the roller and spacer with the top holes in the

brackets and secure them with the bolt and nut.

Adjusting the Blade

To ensure proper operation of the cutting unit, there must be

10-16 mm (0.38-0.62 inch) clearance between the tips of the

wing and center cutting unit blades (

).

1.

Raise cutting unit so blades are visible and block center

deck section so it cannot fall accidentally. Wing decks

must be horizontal to center cutting unit.

2.

Rotate a center and adjoining wing blade so there blade

tips are aligned. Measure distance between blade tips,

distance should be approximately 10-16 mm (0.38-0.62

inch) (

29

Содержание 30604

Страница 14: ...130 6042 1 Read the Operator s Manual for maintenance information 14...

Страница 37: ...Service Interval Chart Figure 34 37...

Страница 58: ...Notes 58...