•

Read all attachment manuals.

•

Ensure that the area is clear of other people before

operating the traction unit. Stop the traction unit

if anyone enters the area.

•

Never leave a running traction unit unattended.

Always lower the loader arms, stop the engine, set

the parking brake, and remove the key before leaving.

•

Do not exceed the rated operating capacity, as the

traction unit may become unstable which may result

in loss of control.

•

Do not carry a load with the arms raised. Always

carry loads close to the ground.

•

Do not over-load the attachment and always keep

the load level when raising the loader arms. Logs,

boards, and other items could roll down the loader

arms, injuring you.

•

Never jerk the controls; use a steady motion.

•

Watch for traffic when operating near or crossing

roadways.

•

Do not touch parts which may be hot from

operation. Allow them to cool before attempting to

maintain, adjust, or service.

•

Check for overhead clearances (i.e. branches,

doorways, electrical wires) before driving under any

objects and do not contact them.

•

Ensure that you operate the traction unit in areas

where there are no obstacles in close proximity to the

operator. Failure to maintain adequate distance from

trees, walls, and other barriers may result in injury

as the traction unit backs up during operation if the

operator is not attentive to the surroundings. Only

operate the unit in areas where there is sufficient

clearance for the operator to safely maneuver the

product.

•

Before digging, have the area marked for

underground utilities, and do not dig in marked areas.

•

Locate the pinch point areas marked on the traction

unit and attachments and keep hands and feet away

from these areas.

•

Before operating the traction unit with an

attachment, ensure that the attachment is properly

installed.

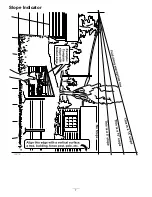

Slope Operation

Slopes are a major factor related to loss-of-control and

tip-over accidents, which can result in severe injury or

death. All slopes require extra caution.

•

Do not operate the traction unit on hillsides or

slopes exceeding the angles recommended in the

Stability Data section in , page , and those in the

attachment

Operator’s Manual

. See also the , page .

•

Operate up and down slopes with the heavy end

of the traction unit uphill.

Weight distribution

changes. An empty bucket will make the rear of

the traction unit the heavy end, and a full bucket

will make the front of the traction unit the heavy

end. Most other attachments will make the front of

traction unit the heavy end.

•

Raising the loader arms on a slope will affect the

stability of the machine. Whenever possible, keep the

loader arms in the lowered position when on slopes.

•

Removing an attachment on a slope will make the

rear of the traction unit heavy. Refer to the Stability

Data section in , page , to determine whether the

attachment can be safely removed on the slope.

•

Remove obstacles such as rocks, tree limbs, etc. from

the work area. Watch for holes, ruts, or bumps, as

uneven terrain could overturn the traction unit. Tall

grass can hide obstacles.

•

Use only Toro-approved attachments. Attachments

can change the stability and the operating

characteristics of the traction unit. Warranty may be

voided if used with unapproved attachments.

•

Keep all movements on slopes slow and gradual. Do

not make sudden changes in speed or direction.

•

Avoid starting or stopping on a slope. If the traction

unit loses traction, proceed slowly, straight down the

slope.

•

Avoid turning on slopes. If you must turn, turn

slowly and keep the heavy end of the traction unit

uphill.

•

Do not operate near drop-offs, ditches, or

embankments. The traction unit could suddenly turn

over if a track goes over the edge of a cliff or ditch,

or if an edge caves in.

•

Do not operate on wet grass. Reduced traction could

cause sliding.

•

Do not park the traction unit on a hillside or slope

without lowering the attachment to the ground,

setting the parking brake, and chocking the tracks.

Maintenance and Storage

•

Disengage the auxiliary hydraulics, lower the

attachment, set the parking brake, stop the engine,

and remove the key. Wait for all movement to stop

before adjusting, cleaning, or repairing.

•

Clean debris from attachments, drives, mufflers, and

engine to help prevent fires. Clean up oil or fuel

spillage.

5

Содержание 22319

Страница 7: ...Slope Indicator 7...

Страница 49: ...Schematics G007388 Electrical Schematic Rev B 49...

Страница 50: ...Hydraulic Schematic Rev A 50...

Страница 51: ...Notes 51...