12

Before Operating

Before operating, check the fuel and oil level, remove

debris from the traction unit, and check the tire pressure.

Also, ensure that the area is clear of people and debris.

You should also know and have marked the locations of

all utility lines.

Adding Fuel

Danger

In certain conditions, fuel is flammable and

explosive. A fire or explosion can burn you and

others and can damage property.

•

Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any fuel that

spills.

•

Do not fill the fuel tank completely full. Add

fuel to the fuel tank until the level is 1/4 to 1/2

in. (6 to 13 mm) below the bottom of the filler

neck. This empty space in the tank allows fuel

to expand.

•

Never smoke when handling fuel, and stay away

from an open flame or where fuel fumes may be

ignited by a spark.

•

Store fuel in an approved container and keep it

out of the reach of children. Never buy more

than a 30-day supply.

The engine runs on clean, fresh diesel fuel with a

minimum cetane rating of 40. Purchase fuel in quantities

that can be used within 30 days to ensure fuel freshness.

Use summer grade diesel fuel (No. 2-D) at temperatures

above 20

°

F (–7

°

C) and winter grade diesel fuel (No. 1-D

or No. 1-D/2-D blend) below 20

°

F (–7

°

C). Use of

winter grade diesel fuel at lower temperatures provides

lower flash point and pour point characteristics, allowing

easier starts and lessening the chances of chemical

separation of the fuel due to lower temperatures.

Use of summer grade diesel fuel above 20

°

F (–7

°

C) will

contribute toward longer life of the fuel pump

components.

Important

Do not use kerosene or gasoline in place of

diesel fuel. Failure to observe this caution will damage

the engine.

1. Park the traction unit on a level surface, lower the

loader arms, and stop the engine.

2. Remove the key and allow the engine to cool.

3. Clean around the fuel tank cap and remove the cap.

4. Use a funnel and add diesel fuel to the fuel tank, until

the level is 1/4 to 1/2 inch (6 mm to 13 mm) below the

bottom of the filler neck.

Note: This space in the tank allows fuel to expand. Do not

fill the fuel tank completely full.

5. Install the fuel tank cap securely. Wipe up any fuel that

may have spilled.

If possible, fill the fuel tank after each use. This will

minimize possible buildup of condensation inside the fuel

tank.

Draining Water from the Fuel

Filter

Drain water or other contaminants from the fuel filter

daily.

1. Stop the engine and remove the key.

2. Open the rear access cover; refer to Opening the Rear

Access Cover, page 23.

3. Turn the drain valve until the water runs out of the

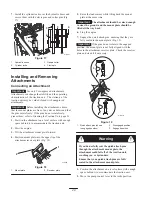

filter (Fig. 6).

Note: The fuel filter is located near the bottom of the fuel

tank.

m–3708

1

2

Figure 6

1.

Fuel filter

2.

Drain valve

4. Close the valve.

5. Close the rear access cover.

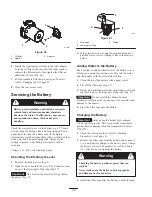

Checking the Oil Level

1. Park the traction unit on a level surface, lower the

loader arms, and stop the engine.

2. Remove the key and allow the engine to cool.

3. Open the rear access cover; refer to Opening the Rear

Access Cover, page 23.

4. Clean around the oil dipstick (Fig. 7).

Содержание 22303

Страница 6: ...6 Slope Chart...

Страница 35: ...35...