centerline of F-5 up to the top sheeting and the other

from the centerl ine of F-5 down to the bottom edge of

the fuselage. This completes the sheeting of the

front end of the airplane. If you have taken your time

and fitted these pieces with a minimum amount of

gaps, all that remains is sanding to shape.

21. Use a sanding block to bevel the inside ends of the

spruce fuselage framework at the tailpost—see

plans. Once satisfied, glue these ends accurately

together providing equal bends to each side of the

fuselage. Now accurately cut and glue in place all of

the remaining spruce and balsa cross braces as

shown.

22. Once again, accurately position the wing center sec-

tion in place on the fuselage. Using the trailing edge

as your mark, finish sheeting the top of the fuselage,

cross grain, back to the point where the fuselage

sides end. Remove the center section from the

fuselage.

23. With the exception of final sanding and rounding as

shown on the plans, the fuselage is now complete.

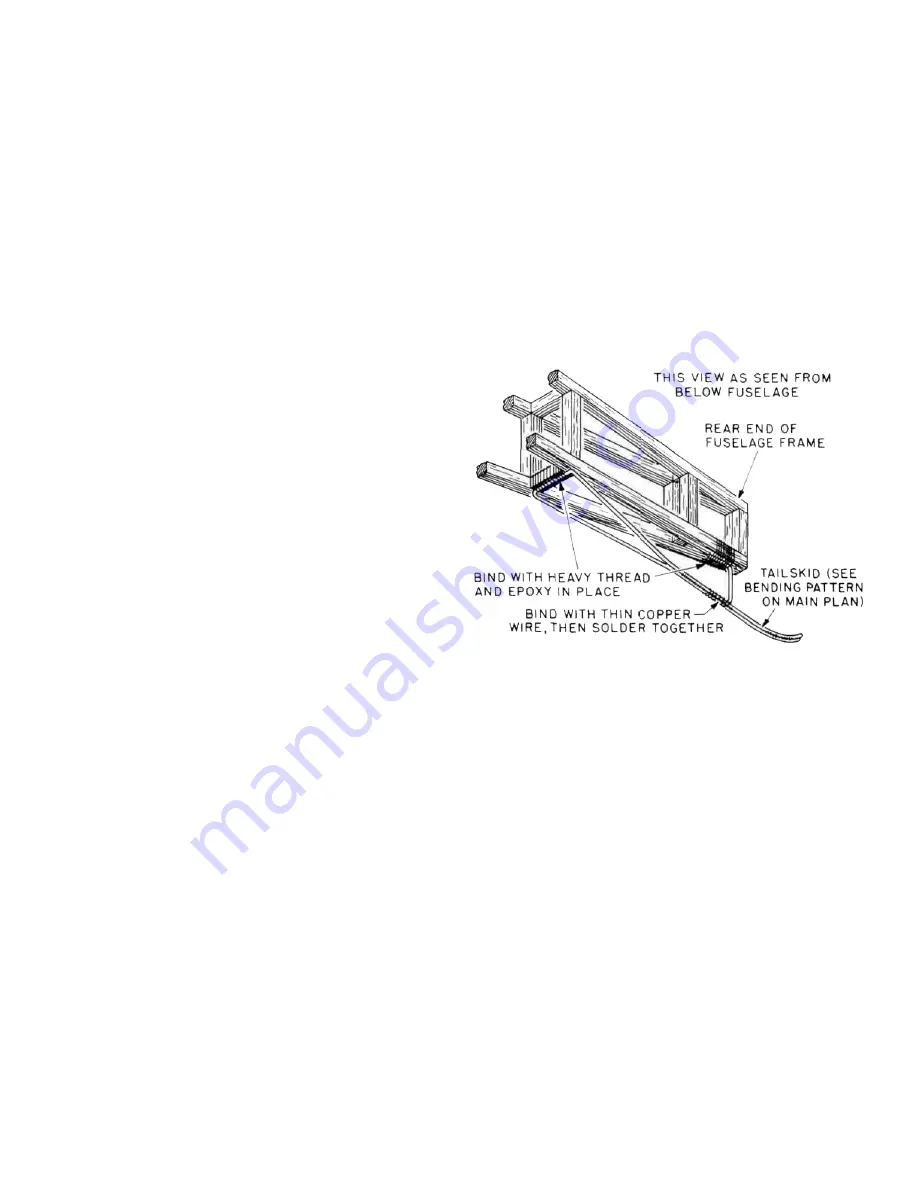

LANDING GEAR AND TAILSKID ASSEMBLY

Note that the front and rear 1/8" dia. M.W. landing gear

forms are supplied to you pre-bent. Note on the plans

that they must be joined together at the bottom, towards

the wheels. We recommend soft copper wire for first

firmly wrapping the two pieces together followed by

soldering the legs together. We would highly recom-

mend the use of HARRIS'S STAY-CLEAN FLUX and their

silver solder for this operation. Although a soldering iron

will work with patience, these joints can be quickly and

permanently made with the use of a small hobby-type

gas torch.

1. Locate the position of the rear "crossed-axle" wire

to the bottom rear ply L/G plate on the fuselage bot-

tom. While holding the wire in place, slip the two

formed metal clips onto the wire. Using a pencil to

mark the hole locations of these clips onto the ply

base, remove the wire and clips. Drill shallow, small

diameter "guide holes" for the clip's screws. Now

attach the landing gear wire to the fuselage with the

clips and the #2 x 3 / 8 " screws provided—there is no

need to overtighten them. Repeat this process with

the forward landing gear wire.

2. Pull the two components together until they touch.

The two short bent "arms" on the forward leg should

line-up with the legs of the rear L/G wire. If needed,

use pliers to adjust these arms until they neatly fit.

3. Use soft copper wire to now neatly wrap the forward

short arms to the rear L/G wire as shown on the

plans. Apply some STAY-CLEAN flux to the joint and

solder. Repeat the process on the other side. Be neat

and try and be sure that the joint is at once solid

without a lot of excess solder. Once satisfied, com-

pletely clean the solder joints of any flux.

4. As shown, the crossed-axle landing gear system

derives its ability to accept landing loads and shock

from the two (2) independent axle legs. These need

to be joined at two points, each 2-1/2" in from the

wheels. This distance has shown very good shock-

absorbing ability for Elders weighing 3-3-1/2 lbs. Join

these axles by first measuring the 2-1/2" distance re-

quired, wrapping with soft wire (about 3/8") and

soldering. Again, clean the solder joints completely.

5. The same process is now used to make the rear

tailskid assembly. First bend the 1/16" dia. M.W. pro-

vided to the shape shown using pliers. Wrap the tip

of the skid with soft copper wire and solder. Now

tape the main skid wire in place to the bottom'rear of

the fuselage. Locate the pre-bent tailskid support

wire and wrap it in place to the tailskid with soft wire.

Solder it in place to the skid. Remove the assembly

from the fuselage and again, clean the solder joints

completely.

6. Remove the main landing gear from the fuselage.

The landing gear and tailskid are now complete and

can be used as is or painted flat black or aluminum

(we use K&B epoxy paints for this as well as other

painting needs on this airplane). As we did on some

of our prototypes, you may wish to add wood back-

ing to the wires, sand these to airfoil shape and paint

them a wood color—looks great! We used 1/8" x 1/4"

hard balsa with a 1/8" dia. "groove" sanded into one

edge, carefully fitting the piece in place. We glued

the wood to the metal with thick CA adhesive and

sanded the whole affair smooth. Then we used clear,

paintable Monokote to cover the "wooded" parts of

the landing gear to provide a one-piece look and air-

brushed wood-colored epoxy paint on the whole

thing.

FINAL ASSEMBLY

1. Locate one of the 1/4" dia. by 3-1/2" dowels. Insert the

dowel into the hole previously drilled in the leading

edge of the wing center section. As shown on the

plans, it extends all the way back to the main wing

dihedral brace with about 1/4" - 3/8" of it extending

out to connect with the F-7/F-8 formers; trim the

length as needed. Now install the center section to

the wing with the forward dowel in place. Liberally

8