way, when the fuselage is done, your tank can be in-

serted from the wing opening into the nose and

removed, if needed, with assurance that it is

mounted correctly. Now use a 3/16 "drill bit to drill the

two required holes for the fuel tank (one for fuel feed

and filling and the other for the pressure tap and

overflow). Remove the tank.

12. Drill and tap the holes necessary In the motor mount

to attach your engine (we like to use 4-40 Allen-head

bolts for this purpose). Attach the motor mount to

the firewall and the engine to the mount. By viewing

from the front, determine the location of the throttle

tube housing exit hole. This should be lined-up with

the carb's throttle arm. Drill a 3/16" dia. hole through

the firewall for this tube. Rough-up the outer surface

of the outer throttle tube housing and glue it in place

in the firewall—about 3/16" of it should protrude out

from the face of the firewall, the rest of it runs into

the radio compartment. Be sure your tank still fits

nicely.

13. The servos shown on the plans are of average con-

figuration, however yours may be different; taller,

wider, etc... The Elder will accept almost any radio

system, there is plenty of room. Lay the fuselage

frame over the side view of the plans and take one of

the servos that you plan to use and lay it in place,

about where they are shown on the plans.

Remember that these servos will be mounted on the

1/8" ply servo tray. Observe if your servos will fit. Cut,

fit and glue the 1/4" x 1/2" balsa servo tray bearers in

place between the two uprights in the radio (servo)

compartment—note that their outer edges are flush

with the rest of the fuselage frame

14. You can now sheet the bottom of the fuselage from

the nose (between the two landing gear formers)

back to the last bottom 1/4" x 1/2" cross brace—don't

sheet any further back. Note this sheet is applied

cross grain. Use your sanding block to clean the

edges flush with the frame sides. Sand the landing

gear mounts and sheeting to a smooth curve when

viewed from the side.

15. Use the 3/32" x 4" x 24" balsa sheet provided to now

make the primary fuselage sides. Be economical

here, you will need the rest of this sheeting later. Lay

the fuselage frame on the sheet with the forward

edge of it lined-up with the leading edge of the wing.

Use a pencil to trace the fuselage side outline onto

the sheeting. Cut out the fuselage side and glue it in

place, repeat the process for the other side. Use your

sanding block to again true-up edges and generally

tidy the fuselage.

16. Stand the fuselage on its nose, firewall flat to the

work surface. Locate and glue in place the two side

F-4 formers to the firewall sides, flush with its front

face.

17. Locate and glue in place the two side formers, F-5.

Glue balsa former F-7 to ply former F-8 (see plans).

Glue the F-7/F-8 former in place at the top of the

fuselage where the leading edge of the wing will be.

18. Locate and accurately pin in place the wing center

section to the top of the fuselage—take your time

and locate it as accurately as possible. Use a 1/4"

dia. drill to drill through F-7, F-8, the leading edge

and dihedral brace of the center section—back up

the dihedral brace with a piece of scrap wood to

avoid splintering as the drill bit passes through it.

Remove the center section and set aside for now.

Once again stand the fuselage on it's nose, flat on

the work surface and glue the top F-3 former in place

on top of the firewall and flush with it's front face.

19. Measure, cut and glue in place the top 1/4" sq. balsa

cowl longeron from F-7 through F-3 and out past the

firewall as shown on the plans to pick-up F-2. Cut, fit

and glue the two side 1/4" sq. balsa cowl longerons

to the slots in the F-4's. Now fit in place cowl former

F-2, don't glue yet. Observe how this former is fitting

in place, make sure that it is parallel with the firewall

and that when viewed from the side it is also parallel

with the firewall. Once satisfied, glue it to the three

1/4 " sq. balsa longeron ends. Now glue the two F-1

cowl pieces to the front face of F-2, leaving a 3/32"

"shelf" for mounting the cowling sheet.

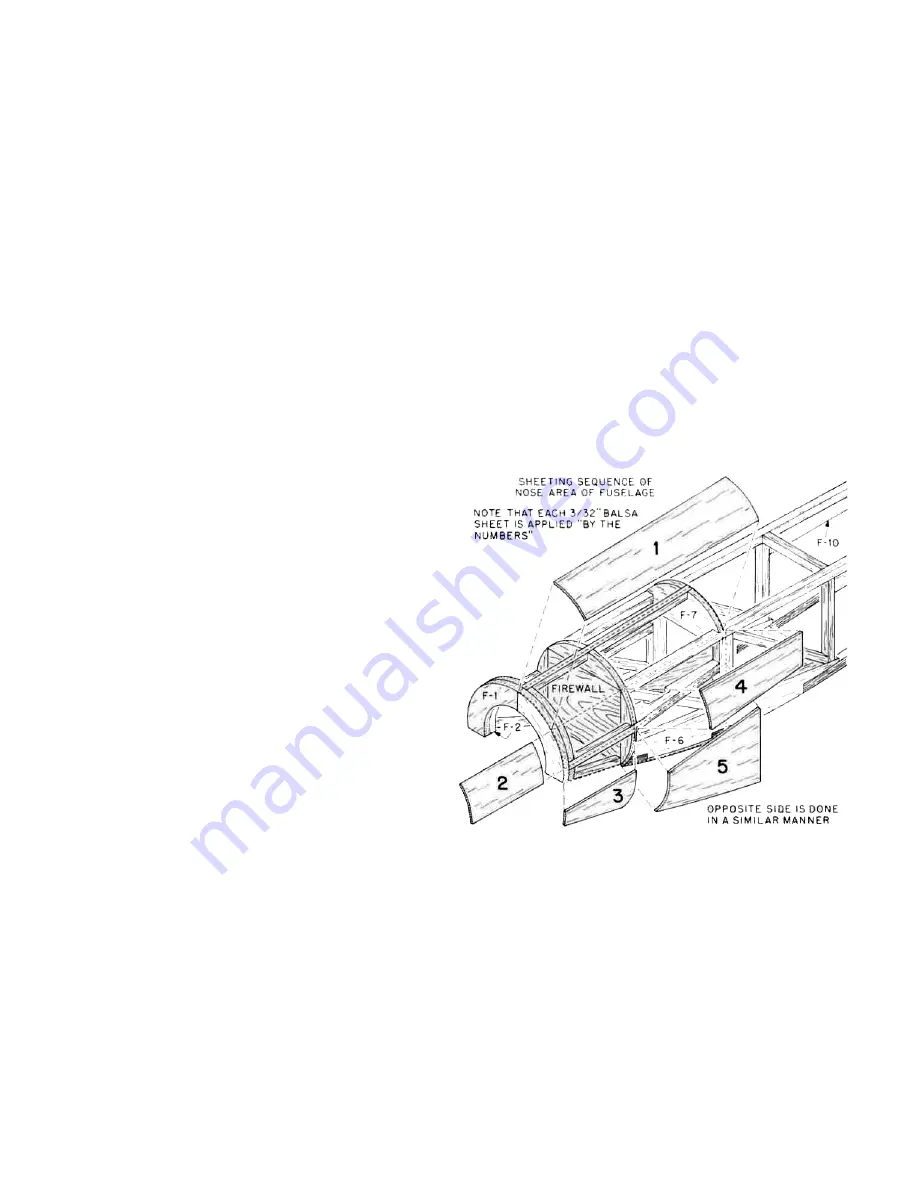

20. You are now going to sheet the nose of the fuselage

as follows: Start by sheeting the top of the fuselage

from F-7 out to F-2. Do this in two pieces with the

seam on the centerline of the top 1/4" sq. balsa

longeron. Wetting the top of the sheet (3/32" balsa

through-out) will help conform it to the formers. Use

thick CA adhesive for this operation; in that way no

pins or tape will be needed. Next, cut and fit a piece

of sheeting that will fit against the edge of the top

sheet, extend down to the centerline of the side 1/4"

sq. balsa cowling longeron and fit between F-1 (on

the top of F-2) and half the thickness of F-4. The next

piece butts up against the edge of the last piece just

installed, down to the bottom of F-1, angling back to

the bottom of F-4. This then leaves only the sides of

the fuselage open at the tank compartment. This

area is done in two pieces also. One from the

7