W W W . T M G I N D U S T R I A L . C O M

P 0 8 / 4 1

T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9

INSTALLATION AND

ASSEMBLY

Do not

lift or move unit without appropriately rated

equipment. Be sure the unit is securely attached to lifting

device used.

Do not

lift unit by holding onto arms, carriage or other

non-approved lifting areas.

Never

use the wood shipping skid for mounting the unit.

Choose a safe location that is in compliance with current

work place safety regulations. Failure to properly install

the machine can lead to improper and unsafe operation.

Machine size is approximately:

75” w x 60” l x 28” h

(1905mm w x 1524mm l x 711mm h)

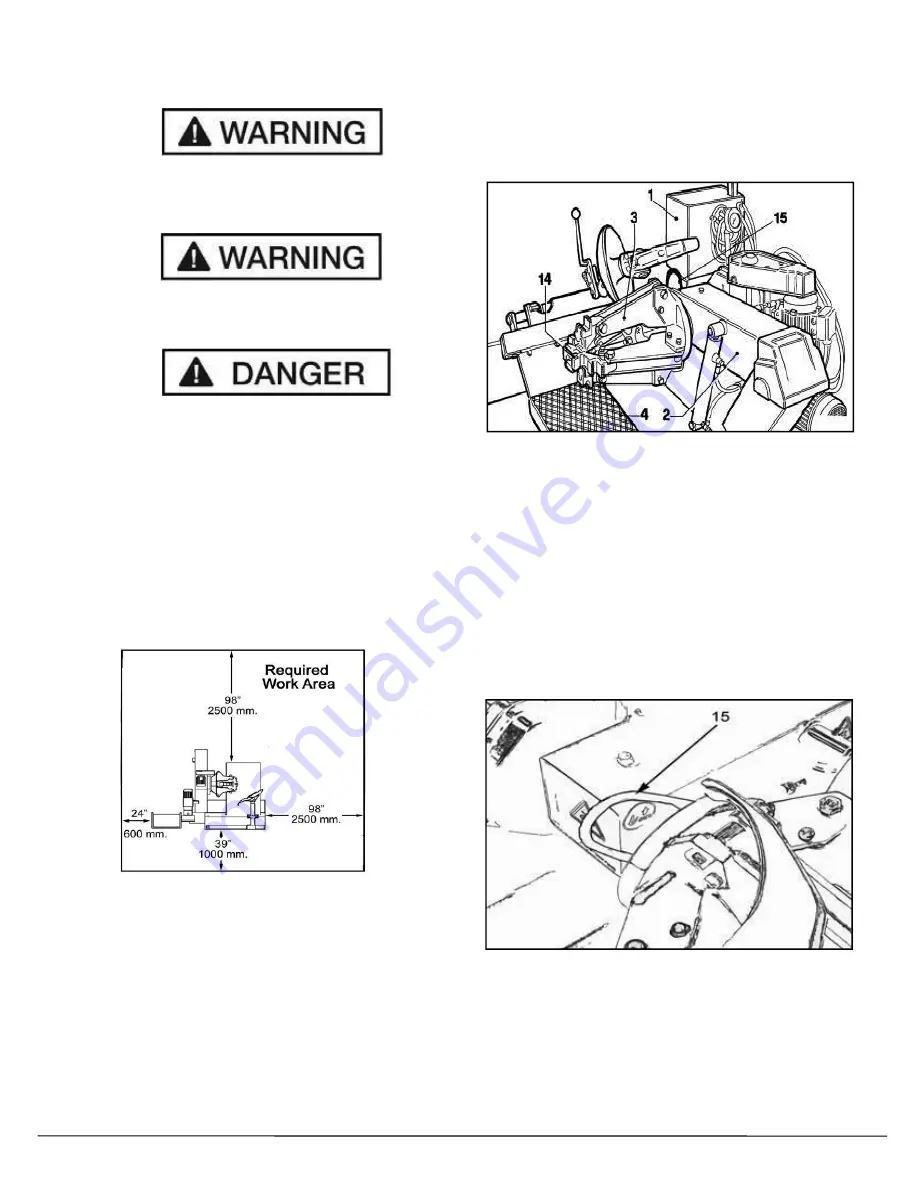

Recommended minimum work area distance from walls

as shown in the diagram.

These measurements are the tire changers working range.

Persons other than specially trained and authorized

operators are expressly forbidden to enter this area.

Transporting / Moving

The tire changer has a lifting ring which has been

positioned specifically for moving the machine.

Before attempting to transport the machine, follow

these instructions:

1) Make sure the horizontal chuck arm (

2

) is completely

lowered.

2) Make sure the chuck jaws (

3

) are closed.

3) Bring the sliding table (

4

) all the way left towards the

horizontal chuck arm.

4) Insert a lifting hook and cable with a minimum lifting

capacity of 1500-pounds (680 kgs.) around the liftingring

(

15

). Make sure the cable is of sufficient length to

properly clear the tire changer when handling.

5) Take precaution to keep track of the cable connecting

the Control Pod while moving the Tire Changer.

6) Lift only with an approved capacity lifting truck or

approved devise that is capable of safely handling the

load.