19

172-65443A-01 (CV-COS) 17 Nov 2014

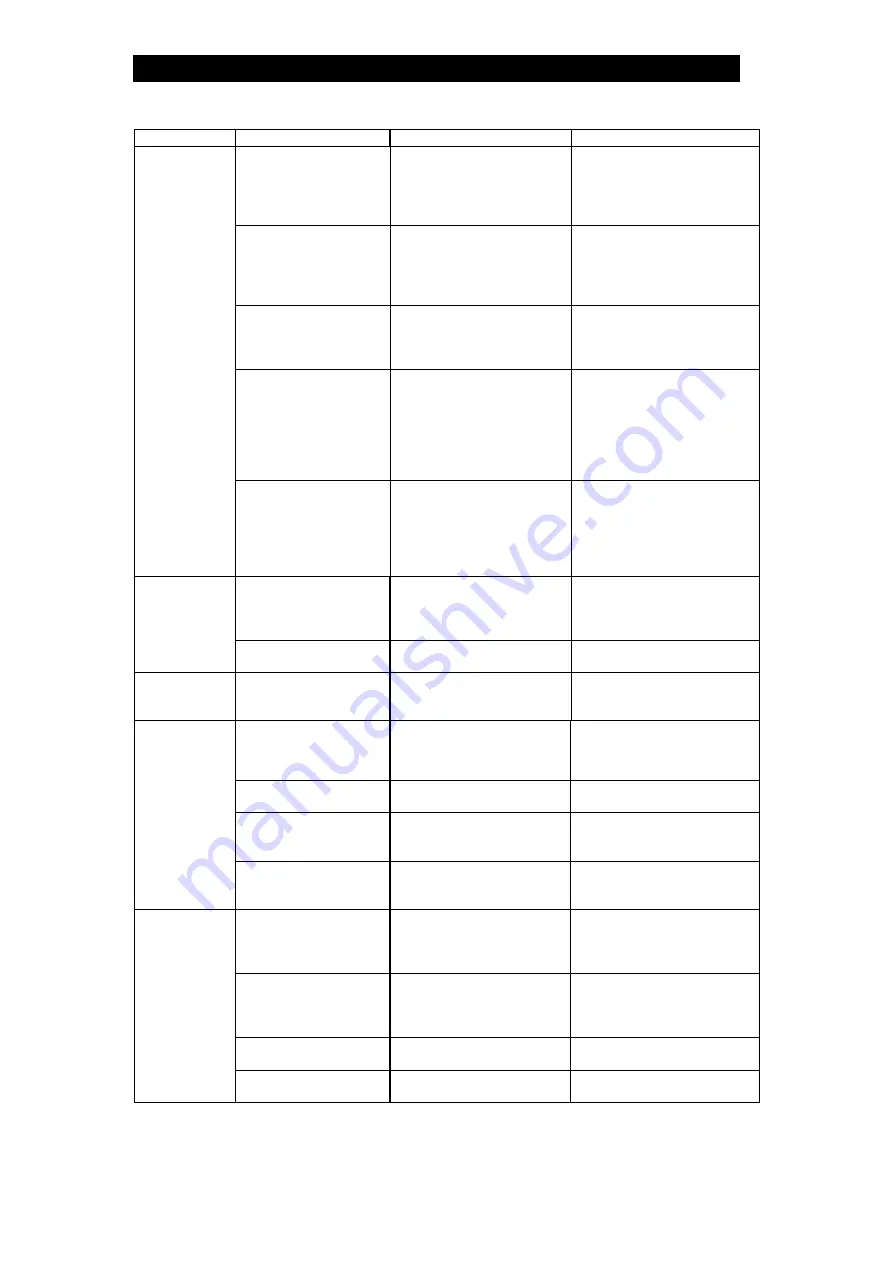

Problem Cause

Diagnosis

Remedy

(Countermeasure)

Air is not being

supplied to the

positioner

Make sure that the

compressor is operating as

it should; make sure that

the regulator connected to

the positioner inlet is set

Initiate the supply of the

designated air supply

pressure to the positioner

(Confirm product

specifications)

The input signal wiring

is incorrectly

connected

Check to make sure the

wiring is connected to the

correct terminals and that

the + and - polarity is not

reversed

Correct the connections

The input signal is not

being input

Check that 4 to 20 mA is

being input by the

positioner connection

terminals

Repair the operation signal

origin or repair the signal

wiring

Positioner’s internal

parts are broken

(the diaphragm is

cracked, etc.)

Check to see if any

unusual noise is coming

from the positioner

Replace with a new

positioner/actuator unit

[Check to make sure that

the valve is not operating

(traveling) too often and

that the ambient

temperature is not too high]

No movement

at all

There is water or oil

inside the positioner

Check to see if there is

water or oil entrained in the

supply air; check to see if

the humidity at the control

valve piping location is too

high

Replace with a new

positioner/actuator unit and

improve the quality of the

air supply

There is water or oil

inside the positioner

Check to see if there is

water or oil entrained in the

air supply

Replace with a new

positioner/actuator unit and

improve the quality of the

air supply

Valve opens

and closes too

slowly

The filter regulator is

clogged

Check the filter

Clean the filter or replace

with a new filter

Valve travel is

unstable

The setting of the

controller is faulty

Check the set value based

on the controller’s PID

parameters

Adjust the controller's

setting values

There is a build-up of

dirt on the trap valve

seat or on the float

Check the trap valve seat

and the float

Clean or replace with a new

trap valve seat or float

The body is installed

tilted

Check the installation

conditions

Correct the installation

The float is deformed

Check the float

Replace with a new float

(Inspect for water hammer

or freezing)

Steam is

blowing

There is vibration in

the piping

Check the piping

conditions

Remove the source of the

vibration or reinforce the

piping supports

The primary pressure

exceeds the trap valve

seat maximum

working pressure

Check the primary

pressure

Change to a suitable

pressure

Water is inside the

float

Check the float

Replace with a new float

(Investigate to see if the

flow medium contains

corrosive substances)

Output piping is

clogged

Check the outlet piping

Clean or modify the piping

No condensate

is discharged

The trap valve seat is

clogged

Check the trap valve seat

Clean or replace with a new

trap valve seat