13

Maintenance

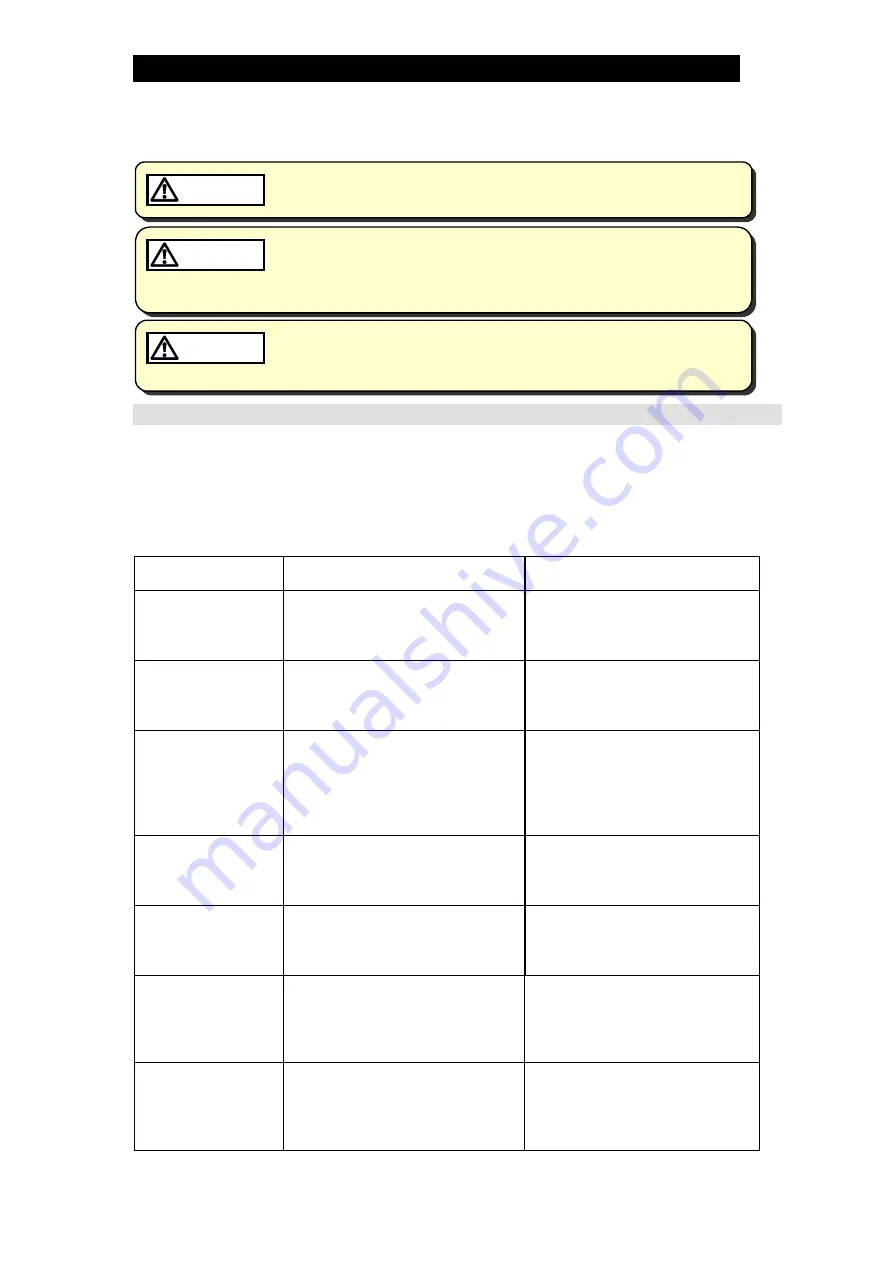

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

An inspection of the following items should be done on a daily basis to determine

whether the product is operating properly or has failed. Periodically (at least

biannually) the operation should also be checked.

In the event of failure (malfunction), also refer to the "Troubleshooting" section for

remedies.

Inspection Item

Inspection Points

Remedy for Failure

(Malfunction)

Leakage from valve

(when the valve is

closed)

Visual inspection or stethoscope

inspection; is the outlet side pressure

or temperature elevated, or is there

the sound of the medium flowing?

Adjust the zero / span; if that

does not solve the problem,

replace with a new valve plug &

stem and valve seat

Leakage from gland

area

Visual inspection; is fluid leaking

from the gap between the gland

and the valve stem, or are there

signs it has leaked previously?

Coat the gland and the valve

stem with grease; if that does

not solve the problem, replace

with new V-rings

Air leakage from

actuator

Visual inspection or stethoscope

Inspection; can the sound of a

large amount of air leaking from

the actuator area or the exhaust

tap during stable actuator

operation always be heard?

Replace with a new actuator unit

Leakage from the

gaskets between

any pressurized

parts

Visual inspection; is fluid leaking

from the gasket areas on

pressurized parts?

Apply additional tightening (refer

to recommended torque) or

replace with new gaskets

Leakage from

pressurized parts

such as body and

valve bonnet

Visual inspection; is fluid leaking

from pressurized parts such as

the body or valve bonnet?

Replace any pressurized parts at

leak locations

Leakage from the

trap area

Visual inspection or stethoscope

inspection; is live steam being

discharged from the trap outlet

piping, or can the sound of a

steam leak be heard?

Clean the sealing surface of the

trap valve seat or replace the

valve seat

Operating conditions Visual inspection; does the actual

valve travel differ from the

designated operation signal value?

Readjust the air pressure

reducing valve and positioner

zero and span; if that does not

solve the problem, refer to the

"Troubleshooting" section

172-65443A-01 (CV-COS) 17 Nov 2014