10

© Titan Tool Inc. All rights reserved.

cleanup

Special cleanup instructions for use with

flammable solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

• If collecting flushed solvents in a one gallon metal

container, place it into an empty five gallon container, then

flush solvents.

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

IMPORTaNT: The sprayer, hose, and gun should be cleaned

thoroughly after daily use. Failure to do so permits material

to build up, seriously affecting the performance of the unit.

always spray at minimum pressure with the gun

nozzle tip removed when using mineral spirits or

any other solvent to clean the sprayer, hose, or

gun. Static electricity buildup may result in a fire

or explosion in the presence of flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

3. Place the foot valve/shovel valve into a container of the

appropriate solvent.

IMPORTaNT: use only compatible solvents when cleaning

out oil based enamels, lacquers, coal tar, and epoxies.

check with the fluid manufacturer for the recommended

solvent.

4. Place the bleed hose into a metal waste container.

5. Set the pressure to minimum by turning the pressure

control knob fully counterclockwise.

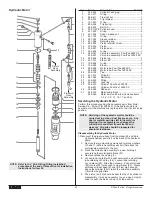

Hydraulic Shut-off

Valve (in open

position)

Pressure Control

Knob

Bleed Valve

6. Open the hydraulic shut-off valve located on the hydraulic

pressure hose. The handle should be in line with the

hose.

7. Open the bleed valve by turning the bleed valve knob fully

counterclockwise.

8. Start the engine or turn on the electric motor.

9. Allow the solvent to circulate through the sprayer and

flush the paint out of the bleed hose into the metal waste

container.

10. Turn off the sprayer.

11. Close the bleed valve by turning the bleed valve knob fully

clockwise.

12. Start the engine or turn on the electric motor.

Ground the gun by holding it

against the edge of the metal

container while flushing. Failure to

do so may lead to a static electric

discharge, which may cause a fire.

13. Trigger the gun into the metal waste container until the

paint is flushed out of the hose and solvent is coming out

of the gun.

14. Continue to trigger the spray gun into the waste container

until the solvent coming out of the gun is clean.

NOTE: For long-term or cold weather storage, pump

mineral sprits through the entire system.

15. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

16. Store the sprayer in a clean, dry area.

IMPORTaNT: Do not store the unit under pressure.

cleaning a clogged Tip

1. Follow the “Pressure Relief Procedure” in the Operation

section of this manual.

2. If the tip clogs, rotate the tip handle 180° until the arrow on

the handle is facing the opposite of the spray direction and

the handle clicks in the reverse position.

3. Trigger the gun once so that the pressure can blow the

clog out. NEVER use the tip in the reverse position for

more than ONE trigger pull at a time. This procedure can

be repeated until the tip is free of clogging.

The flow from the spray tip is at very high pressure.

contact with any body part may be dangerous. Do

not place finger on gun outlet. Do not point the

gun at any person. Never operate the spray gun

without the proper tip guard.

Maintenance

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

additionally, follow all other warnings to reduce

the risk of an injection injury, injury from moving

parts or electric shock. always unplug the sprayer

before servicing!

Daily Maintenance

Two daily procedures are required for routine operator

maintenance on this sprayer:

1. Lubricating the upper packings.

2. Cleaning the rock catcher.

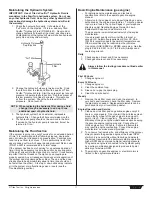

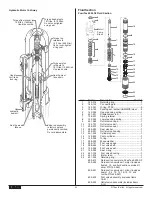

cleaning the Inlet Screen (PowrTex 6900 SF)

Foot Valve

Housing

Inlet

Screen

Retaining

Ring

The inlet screen will clog and must be

cleaned at least once a day.

1. Remove the retaining ring from the

foot valve housing

2. Remove the inlet screen from the

Foot valve housing.

3. Clean thoroughly with the

appropriate solvent.

Lubricating the upper Packings

Packing Oil

Cup

1. Clean out the paint that has seeped

past the upper packings into the

packing oil reservoir above the fluid

section.

2. Fill the packing oil reservoir 1/2 full with

Piston Lube (P/N 314-480) supplied by

the factory. This will extend packing

life.

NOTE: Do not over-fill the reservoir

so that it overflows and drips

into the paint.

Содержание SPEEFLO PowrTex 12000 SV

Страница 35: ...Titan Tool Inc All rights reserved 35 Notes...