12

© Titan Tool Inc. All rights reserved.

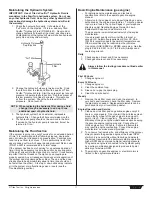

Replacing the Motor Brushes (electric motor)

Perform this procedure using Motor Brush Kit P/N 978-050. The

kit consists of two brushes, two springs, and two clips.

NOTE: Brushes should be replaced when they are worn

to less than 1/2 inch. check and replace both

brushes at the same time.

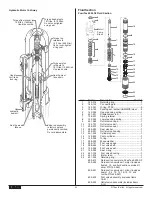

1. Remove both inspection covers on the motor.

Inspection

Cover

2. Push in the spring clip to unhook it, then pull it out.

Terminal Screw

Spring Clip

Brush Lead

3. Loosen the terminal screw. Pull the brush lead away, but

leave the motor lead in place. Remove the brush and

spring.

Commutator

4. Inspect the commutator

for burning, excessive

pitting or gouging. A

black color on the

commutator is normal.

5. Install the new brush

so its lead slides in the

long slot of the brush

holder. Push the terminal

under the terminal screw

washer. Ensure the motor

lead is still connected at

the screw. Tighten the screw.

Brush

Brush

Holder

Terminal

Screw

Spring

Spring Clip

6. Place the spring on the

brush as shown above.

Push in and hook the spring

clip. Repeat this procedure

for the other side.

7. Reinstall both inspection

covers.

If electric motor overloads and stops running,

IMMEDIaTELY turn the motor off and follow the

Pressure Relief Procedure in the cleanup section

of this manual. Wait until the motor cools

(approximately 30 minutes). Then push in the

bubble top, manual reset button, turn the motor on

and pressurize the system.

For cSa approved sprayers only: The ON/OFF switch is

also the RESET!

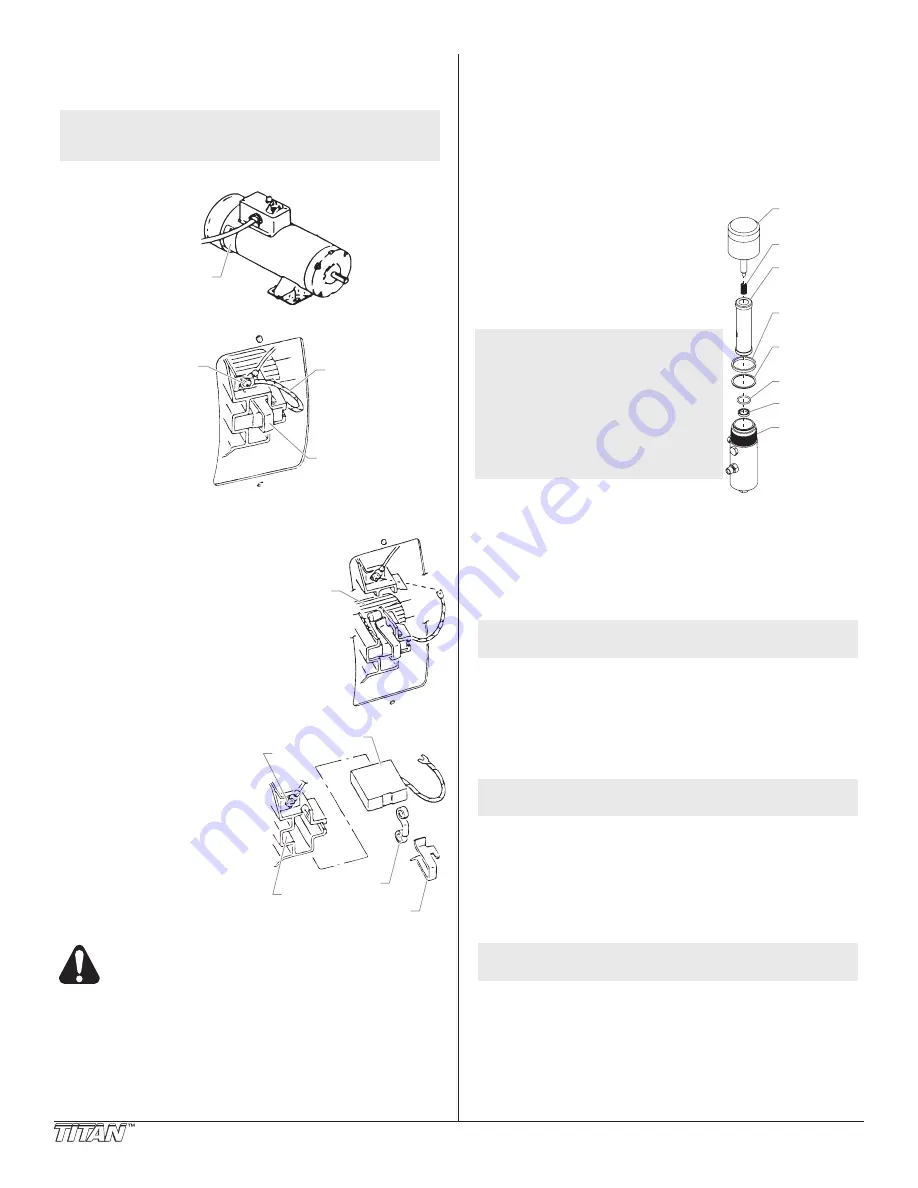

Maintaining the Filter assembly (optional

accessory)

Clean the filter regularly. Dirty or clogged filters can greatly

reduce filtering ability and cause a number of system problems

including poor spray patterns, clogged spray tips, etc.

cleaning

To clean the filter, perform the following procedure.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

Filter Cap

Assembly

Filter

Element

w/Ball

PTFE

Gasket

(thick)

PTFE

Gasket

(thin)

PTFE

O-ring

Carbide Seat

Filter Body

Spring

2. Remove the filter cap assembly

and spring.

3. Pull the filter element with ball

straight out of the filter body.

4. Clean inside the filter body, filter

element with ball, and filter cap

assembly using the appropriate

solvent.

NOTE: use care in handling parts

as dirt, debris, scratches, or

nicks may prevent o-rings or

gaskets from sealing.

This filter element filters

from the inside out. Be sure

to clean the filter element

thoroughly on the inside.

Soak in solvent to loosen

hardened paint or replace.

Inspection

Inspect all parts of the filter assembly before reassembly.

1. Inspect the ball inside the filter element. If the ball has

pressure cuts or scratches, replace the filter element.

a. If the ball is cut, remove the

PTFE

o-ring using an o-ring

pick and remove the carbide seat.

b. Check the seat for nicks or grooves. If the seat is

damaged, replace.

NOTE: Removal of the

PTFE

o-ring will damage the

o-ring and require replacement.

2. Remove the spring from the spring guide on the filter cap.

a. Measure the length of the spring uncompressed. If it

measures less the 3/4” from end to end, replace.

b. Push the spring back onto the spring guide until it

“snaps” back into position.

3. Inspect the two

PTFE

gaskets and the

PTFE

o-ring for

deformity, nicks, or cuts. Replace, if needed.

NOTE: The

PTFE

gaskets,

PTFE

o-ring, and spring are

packaged in Filter Service Kit P/N 930-050.

Reassembly

After cleaning and inspecting all parts, reassemble the filter.

1. Place the carbide seat into the filter body. Make sure the

beveled side of the seat is facing up.

2. Place the

PTFE

o-ring into the groove on the outer

diameter of the carbide seat.

3. Place the filter element with ball into the filter body.

NOTE: The top and bottom of the filter element with ball

are identical.

4. Push the spring back onto the spring guide of the filter cap

until it “snaps” back into position, if not already done.

5. Place the thin

PTFE

gasket onto the step at the top of the

filter body.

6. Place the thick

PTFE

gasket onto the top of the thin

gasket.

7. Tighten the filter cap assembly onto the filter body.

Содержание SPEEFLO PowrTex 12000 SV

Страница 35: ...Titan Tool Inc All rights reserved 35 Notes...