© Titan Tool Inc. All rights reserved.

27

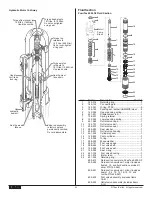

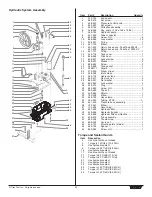

Item Part #

Description

Quantity

1

143-019

Retaining ring ...........................................1

2

143-120

Connecting pin..........................................1

3

145-031

O-ring,

PTFE

............................................2

4

138-153

Packing set, leather/UHMWPE/steel

........2

5

142-004

Upper packing spring................................1

6

144-832

Pump cylinder ...........................................1

7

144-117

Displacement rod......................................1

8

138-001

Spring retainer ..........................................1

9

142-003

Lower packing spring................................1

10

451-085

Outlet valve cage ......................................1

11

138-225

Outlet valve ball ........................................1

12

600-301

Hex screw

.................................................4

13

600-302

Washer .....................................................4

14

600-303

Screw ........................................................1

15

600-304

Pressure plate ..........................................1

16

600-305

Plug plate..................................................1

17

600-306

O-ring ........................................................2

18

600-307

Sealing ring...............................................1

19

600-308

Inlet valve cage.........................................1

20

600-309

Pressure spring ........................................1

21

600-310

Inlet valve ball ...........................................1

22

600-311

Inlet valve seat..........................................1

23

600-312

Grooved pin ..............................................1

24

600-313

Head cap screw ........................................1

25

600-314

O-ring ........................................................1

26

600-315

Plug ..........................................................1

27

600-316

Cap plug ...................................................1

28

600-317

Cleanout adapter ......................................1

29

600-318

O-ring ........................................................1

30

600-320

Outlet valve assembly ..............................1

31

600-321

Cap nut M 6 ..............................................2

32

600-322

Disk spring ................................................4

33

600-323

Rod connector ..........................................1

34

600-324

Hexagon nut M 6

......................................1

35

600-325

Flat screw .................................................1

36

9923504 Disk spring ................................................1

37

600-327

Packing stack ...........................................1

38

600-357

Rod housing assembly .............................1

39

600-328

Retaining ring ...........................................1

40

600-330

O-ring 21 x 2

.............................................1

41

600-331

O-ring 50 x 1.78

........................................1

42

600-332

Groove nut ................................................1

43

600-333

Inlet valve housing ....................................1

44

600-334

O-ring 47 x 2.5

..........................................1

45

600-335

Valve rod ..................................................1

46

600-336

Washer .....................................................1

47

600-337

Shovel valve plate ....................................1

48

600-338

Shovel valve .............................................1

49

600-339

Suction tube..............................................1

600-300

Shovel valve assembly

(includes items 11 – 46)

600-405

Shovel valve service kit, minor

(includes items 1, 3, 4, 10, 11, 17, 18, 21,

36, 37, 41, and and Loctite P/N 426-051)

600-406

Shovel valve service kit, major

(includes items 6, 7, and fluid section

service kit, minor P/N 600-405)

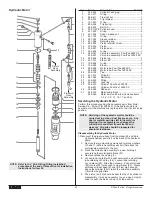

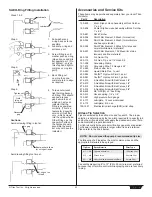

Servicing the PowrTex 6900 SF Fluid Section

IMPORTaNT: use of non-Titan service parts may void

warranty. ask for original parts made by Titan for best

services. This pump should receive a routine servicing

after approximately 1,000 hours of use. Earlier servicing is

required if there is excessive leakage from the top packing

or if pump strokes become faster on one stroke or the other.

The use of Titan Piston Lube (P/N 314-480) is recommended

as an upper packing lubricant. Do not substitute oil, water, or

solvent for an upper packing lubricant.

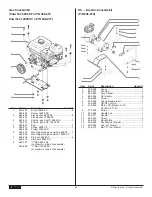

Disassembling the Fluid Section

1. Loosen the shovel valve groove nut (39) by turning it

clockwise using a spanner wrench.

2. Slide the retaining ring (1) up with a small screwdriver,

and push out the connecting pin (2) that connects the

displacement rod (7) to the hydraulic piston rod.

3. Unscrew the shovel valve assembly from the pump

cylinder (6).

4. Pull down the shovel valve assembly and remove the

entire displacement rod assembly (7) with the shovel valve

assembly from the pump cylinder (6).

5. Using two wrenches, remove the outlet valve assembly

(30) from the shovel valve rod connector (33). Set aside

the shovel valve assembly.

6. Using a strap wrench, remove the pump cylinder (6) from

the motor pump block.

7. Remove the

PTFE

o-ring (3), upper packing spring (5),

and upper packing set (4) from the motor/pump block.

8. Hold the displacement rod (7) in a vise by the flats at

the top of the displacement rod. Remove the outlet

valve assembly (30) with a wrench while holding the

displacement rod horizontal with a wooden support, if

necessary. Remove the outlet valve ball (11), outlet valve

cage (10), lower packing set (4), lower packing spring (9),

and spring retainer (8).

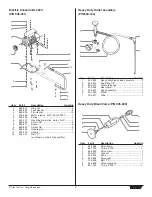

Reassembling the Fluid Section

1. After soaking the new leather packings in oil (preferably

linseed oil), reassemble the lower packing set (4). Place

the set onto the outlet valve assembly (30) with the peak

of the “V” packings pointing down toward the hex on the

outlet valve assembly.

NOTE: all leather packings must be soaked in oil for

15–20 minutes before installation. Soaking the

packings too long will cause the packings to

swell and create difficulty during reassembly.

2. Insert the outlet valve cage (10) and new outlet valve ball

(11) into the displacement rod (7).

3. Clean the threads on the outlet valve assembly (30) and

coat the threads with blue Loctite #242. Make sure the

Loctite is only on the threads.

4. Place the lower packing spring (9) onto the outlet valve

assembly (30) followed by the spring retainer (8).

5. Screw the displacement rod (7) and the outlet valve

assembly (30) together. Tighten in a vise to 900 in./lbs.

(75 ft./lbs.).

6. Insert the

PTFE

o-ring (3) into the upper grove of the

motor/pump block.

7. Insert the upper packing set (4) into the motor/pump block

with the peak of the “V” packings pointing up toward the

motor.

8. Place the upper packing spring (5) into the motor/pump

block with the small tapered end facing up toward the

motor/pump block.

9. Thread the short threads of the pump cylinder (6) into the

motor/pump block and tighten with a strap wrench.

10. Make sure the retaining ring (36) is in the groove above

the threads on the pump cylinder.

11. Locate the shovel valve assembly and thread the outlet

valve housing (30) onto the shovel valve rod connector

(33). Tighten securely using two wrenches.

12. Insert the displacement rod (7) with the shovel valve

assembly up through the pump cylinder and the upper

packings in the motor/pump block.

13. Thread the shovel valve assembly onto the pump cylinder

(6) until it stops and then back off until it reaches the

desired position.

14. Align the holes in the displacement rod (7) and the

hydraulic piston rod and insert the connecting pin (2).

Replace the retaining ring (1) over the connecting pin.

15. Apply a small amount of blue Loctite #242 to the inside

threads of the shovel valve groove nut (39). Tighten the

groove nut securely by turning it counterclockwise using a

spanner wrench.

Содержание SPEEFLO PowrTex 12000 SV

Страница 35: ...Titan Tool Inc All rights reserved 35 Notes...