3515 Flex-Wing Rotary Cutter

48

Titan Implement, LLC

February 2020

(423) 334-0012

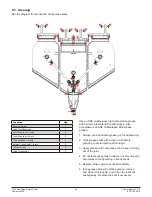

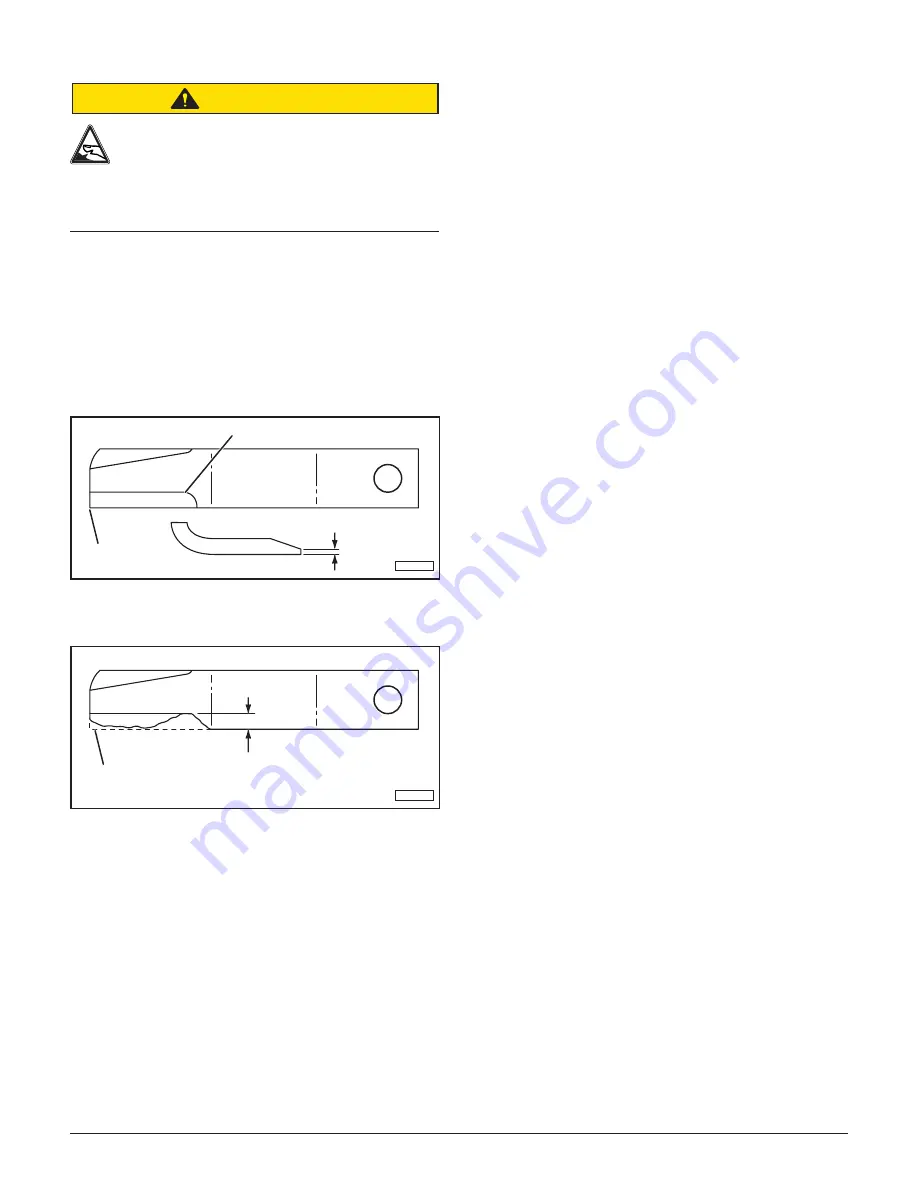

9.6.3 Blade Sharpening

CAUTION

Sharp Object Hazard

The grinder may catch on the blade during

sharpening, propelling it forcefully. To

prevent the possibility of serious injury, make sure

blades are secured against movement while

sharpening.

When sharpening blades, always sharpen both blades

at the same time and grind the same amount on each

blade to maintain balance. Unbalanced blades will

cause excessive vibration, which can damage gearbox

bearings. Vibration may also cause structural cracks

to the rotary cutter. Follow the original sharpening

pattern. Do not sharpen blades to a razor edge; leave

a 1/16” blunt edge. Do not sharpen the back side of

the blade. Do not heat and pound out the edge.

1/16”

FOLLOW ORIGINAL PATTERN

MAINTAIN

CORNER

TI-00064

Replace the blades when worn more than 1/2” from the

original edge. Always replace blades in pairs.

ORIGINAL

BLADE EDGE

1/2” MAXIMUM

TI-00063

9.7 Blade Carrier Removal

1. Remove the cotter pin and loosen the castle nut on

the gearbox shaft. Do not remove the nut until the

blade carrier is loosened.

2. Use a suitable two jaw gear puller to pull the carrier

off the tapered gearbox shaft.

3. If a gear puller is not available, insert a bar through

the blade bolt access the hole with the end against

the blade carrier. Strike the opposite end of the bar

sharply. Rotate the blade carrier 180 degrees and

repeat until the carrier breaks loose.

4. Remove the castle nut and the blade carrier.

9.8 Blade Carrier Installation

1. Clean the splines on both the blade carrier and the

output shaft.

2. Position the carrier on the gearbox output shaft and

install the castle nut. Tighten the nut to a minimum

450 ft. lbs.

3. Strike the carrier near the hub several times with

a heavy hammer to seat the hub. Use care not to

strike the nut or the end of the shaft.

4. Retighten the nut to 700 ft. lbs.

5. Install the cotter pin and spread the tangs.

9.9 Slip Clutch Operational Check

The rotary cutter is equipped with three slip clutches,

with one located in front of each spindle gearbox. The

slip clutches serve as overall protection for the tractor,

driveline, and gearboxes. Even though new clutch

assemblies are “run-in” and checked for torque prior

to shipment, readjustment may be advisable if the

clutch has been exposed to weather for an extended

period of time. The clutch facing and plates should be

inspected for rust and/or corrosion. After the rotary

cutter has been stored for thirty days or more, perform

the following check:

1. Make a trial run in the heaviest operating conditions

expected. If any clutch slips noticeably, tighten the

eight adjusting bolts no more than 1/2 turn between

trial runs until the clutch slippage is reduced.

2. Scribe a mark across the clutch facing of each

slip clutch. When subjected to shock loads, a

separation of the marks will assure that the clutch

setting is correct.

Note:

Check the clutches periodically during the first

hour of operation for excessive heat build-up

due to unexpected slippage.

If a clutch is being rebuilt (new facing and/or plates),

it is necessary to “run-in” these parts prior to final

adjustment. The plates should be thoroughly cleaned

and free of foreign material, as well as being checked

for warping with a straight edge. Warped plates cannot

be adjusted properly and will not hold. To accomplish

the “run-in” after assembly, follow this procedure:

1. Tighten all the adjusting bolts evenly until the clutch

cannot be slipped by hand.

2. With the blade carrier locked in a stationary position,

operate with the PTO at idling speed (approximately

100 RPM), until evidence of heating is noted.

Do

not allow the clutch to overheat.

Содержание 3515

Страница 1: ......

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 55: ...Titan Implement LLC 55 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Страница 59: ...Titan Implement LLC 59 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Страница 61: ...Titan Implement LLC 61 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Страница 63: ...Titan Implement LLC 63 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Страница 64: ...3515 Flex Wing Rotary Cutter 64 Titan Implement LLC February 2020 423 334 0012 12 4 Wheel Lift ...

Страница 65: ...Titan Implement LLC 65 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Страница 67: ...Titan Implement LLC 67 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 12 6 Driveline Shield ...

Страница 70: ...3515 Flex Wing Rotary Cutter 70 Titan Implement LLC February 2020 423 334 0012 12 9 Outboard Gearbox ...

Страница 71: ...Titan Implement LLC 71 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 12 10 1 540 RPM Driveline ...

Страница 72: ...3515 Flex Wing Rotary Cutter 72 Titan Implement LLC February 2020 423 334 0012 12 10 2 1000 RPM Driveline ...

Страница 73: ...Titan Implement LLC 73 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 12 10 3 Center Deck Driveline ...

Страница 74: ...3515 Flex Wing Rotary Cutter 74 Titan Implement LLC February 2020 423 334 0012 12 10 4 Wing Deck Driveline ...

Страница 75: ...Titan Implement LLC 75 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 12 11 Wing Deck Driveline ...

Страница 76: ...3515 Flex Wing Rotary Cutter 76 Titan Implement LLC February 2020 423 334 0012 ...

Страница 77: ...Titan Implement LLC 77 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Страница 78: ...Form No 3515M Printed in USA 09 2016 ...