English

English

8

© Titan Tool Inc. All rights reserved.

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

1. Lock the gun by turning the gun trigger lock to the locked

position. If necessary, loosen the gun holder clamp knob and

then engage the spray gun trigger lock. Move the spray gun

to its original position and tighten the clamp knob.

2. Turn the DirectLink pressure control knob fully clockwise to

minimum.

SPRAY

PRIM

E

3. Turn the PRIME/SPRAY knob to the PRIME

position.

4. Turn off the sprayer by pressing and holding

the engine shutoff switch until the motor

shuts off.

5. Unlock the gun by turning the gun trigger lock to the

unlocked position.

6. Fully pull the spray lever on the cart handle to trigger the

spray gun and release any remaining pressure in the hose.

7. Lock the gun by turning the gun trigger lock to the locked

position. If necessary, loosen the gun holder clamp knob and

then engage the spray gun trigger lock. Move the spray gun

to its original position and tighten the clamp knob.

clearing a clogged Tip

If the spray pattern becomes distorted or stops completely while the

trigger is pulled, follow these steps.

1. Place a sheet of cardboard or small

bucket under the spray gun to catch

the paint.

2. Rotate the tip 180º so that the arrow

on the tip handle is pointing opposite

the spray direction.

NOTE: If the tip is difficult to rotate, relieve pressure by 1)

slowly turning the PRImE/SPRAy knob to PRImE, 2)

unlock the spray gun, and 3) squeeze the spray lever.

Release the lever, lock the spray gun, and try rotating

the spray tip again.

3. Make sure the PRIME/SPRAY knob is turned to SPRAY. Unlock

the spray gun.

4. Trigger the gun once so that the pressure can blow the clog

out.

ImPORTANT: Never pull the trigger more than once at time with

the tip in the reverse position.

5. Continue this procedure until the tip is clear of the clog.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument

to clean the tip. The hard tungsten carbide is brittle

and can be chipped.

changing a Spray Tip

Tips can be removed and replaced easily without disassembling the

gun.

Never attempt to change or clean the tip or tip

guard without first performing the “Pressure Relief

Procedure.”

1. Perform the “Pressure Relief Procedure” described in the

sprayer’s Owner’s Manual.

2. Remove the tip from the slot on the tip guard.

3. Insert the new tip into the slot on the tip guard. The arrow on

the tip handle should be pointing in the forward direction for

spraying.

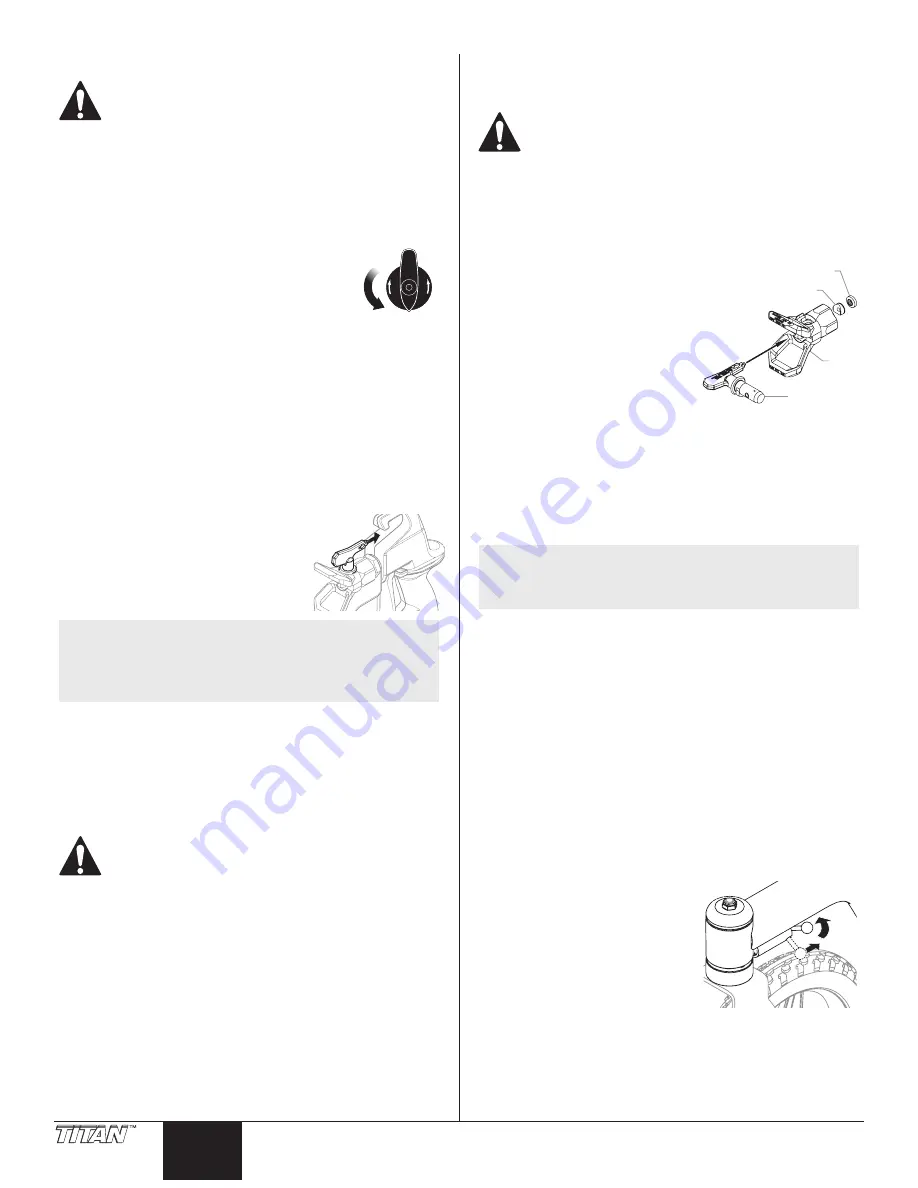

Removing the Seal and Tip Seal

Tip

Guard

Tip

Tip Seal

Retainer

Tip Seal

1. Remove the tip from the tip

guard.

2. Insert the tip handle through

the front of the tip guard.

3. Push the seal and tip seal out

through the back of the tip

guard.

Identifying Tip Sizes

To identify tip sizes, use the following formula. A “1908” tip size will

be used in this example.

The last two digits divided by two represent the size of the spray

pattern when spraying 6” away from the work surface:

08 ÷ 2 = 4” spray pattern

The first two digits represent the diameter of the orifice on the tip:

19 = .019” orifice

NOTE: Worn spray tips will adversely affect the spray

pattern and result in reduced production, poor

finish, and wasted material. Replace worn tips

immediately.

Stenciling

To stencil with this line striper, make multiple spraying passes from

right to left over the stencil with the spray gun connected to the gun

holder. Or, the spray gun can be removed and used independently

from the striper.

To remove the spray gun:

1. Perform the Pressure Relief Procedure in the Operation

section of this manual.

2. Loosen the gun holder block knob on top of the gun holder.

3. Slide the spray gun out of the gun holder.

Operating the Front caster

The front caster on the cart is designed to track the sprayer in either a

straight line or allow free-wheel striping. To adjust the front caster:

1. Pull the handle on the side

of the caster up and back to

release the wheel for free-wheel

striping.

2. To lock the wheel back into

place, pull the handle down.

Once the front wheel is turned

straight again, the wheel will

lock back into place.