8. The cursor will move down to the quantity line. Enter how many parts

you want and press

.

Note: In this example I will tell TigerStop that I want 5 parts.

9. You will be taken to line 2. Repeat steps 7 and 8 until you have

entered all the parts you want to process. Press the [Done] soft key to

exit the list.

The parts list has now been saved. Press [Start] to run the list.

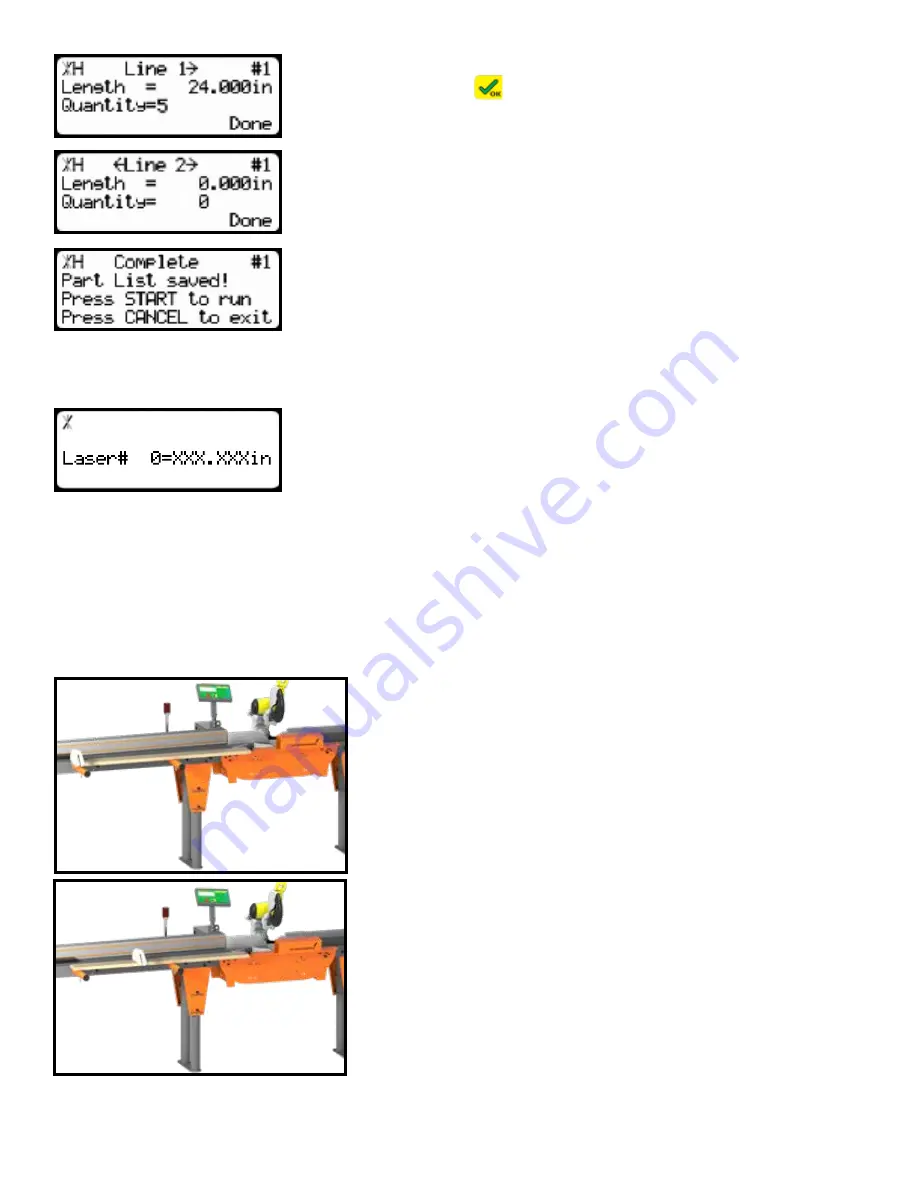

Scan your Stock Material

Once you run the list, the TigerStop screen will display length data from

the defecting laser.

To scan length data, you will use the TigerScan paddle to break the laser beam in certain locaitons.

Place the stock material on the material staging tubes. Butt the material against the bumper.

The TigerScan system uses a series of light tower flashes and beeps to tell the user what the system is

doing.

1. Break the laser beam with the defecting paddle at the end

of the stock material. The light tower will flash and beep one

time.

2. Look down the material length and locate the first defect. If

the material doesnt have any defects, skip to step #. Break

the laser beam slightly before the first defect. The TigerScan

light tower will flash and beep one time.

Содержание TigerScan

Страница 1: ...Made In America 2015 TigerStop LLC Installation Guide Installation Guide TigerScan March 2015 Mk2 ...

Страница 2: ......

Страница 5: ......

Страница 7: ...Attach Material Staging Tubes ...

Страница 16: ......

Страница 17: ......

Страница 18: ......