thermopatch.com

20

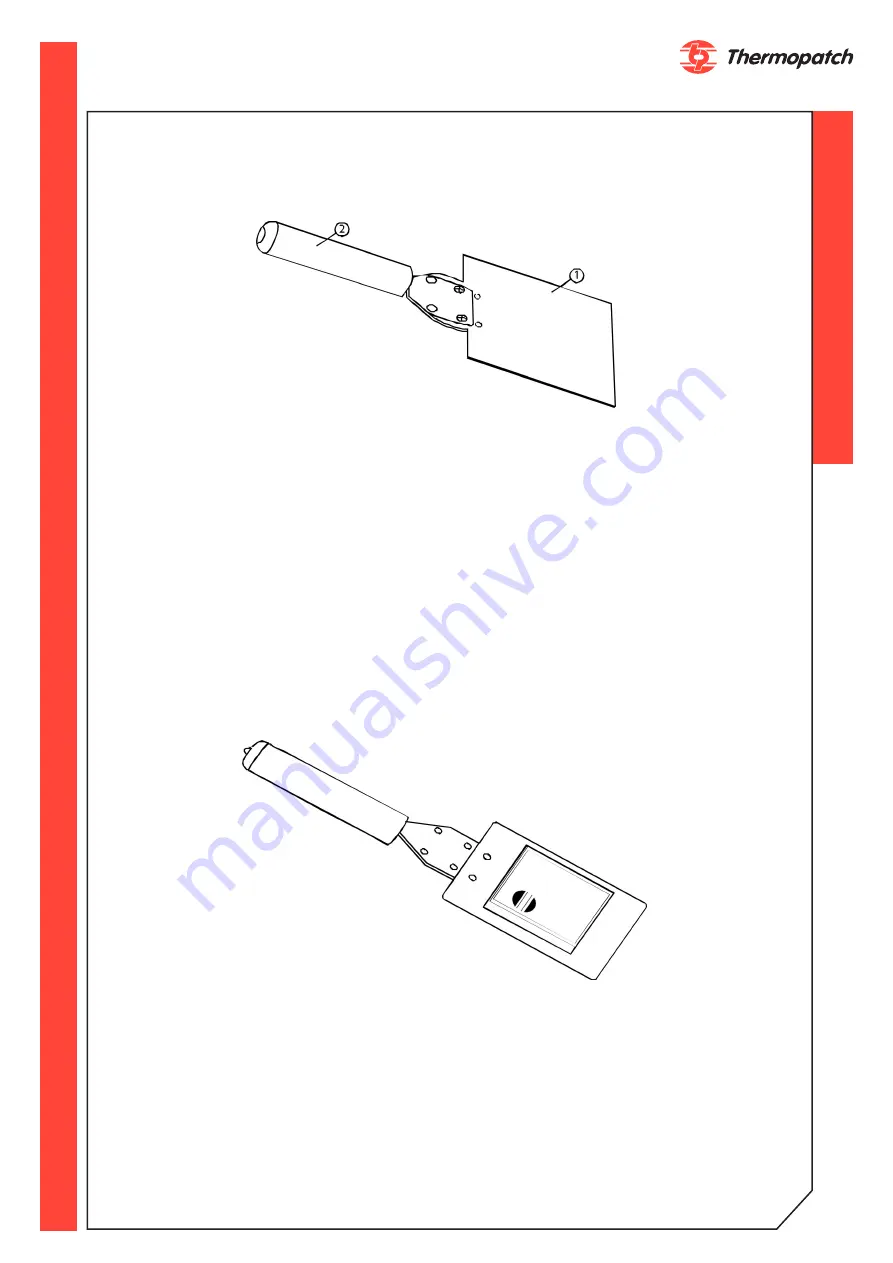

INSERTING THE PRINTING PLATE

The above drawing shows a DP2000T Printing Plate (Item 1) (CUSTOM PART) and a Printing

Plate Holder (Item2) P/N (46007). The Printing Plate Holder is provided for installation and

removal of the Printing Plate.

•

With the artwork facing down on the Printing Plate, apply a downward force just

enough to slide the Printing Plate Holder forward. This locks the Printing Plate into place.

•

Insert the plate into the plate mounting brackets on either side of the iron.

•

Slide the plate in fully.

•

Apply the same downward force and slide the Printing Plate Holder away from the

machine.

To remove the Printing Plate from the machine, just reverse the process. The Printing Plate

is extremely HOT so caution must be taken when removing and placing it on a heat protec-

tive surface. Avoid any side to side motion of the Plate Holder while inserting or withdrawing

Print Plates. This motion tends to bend side guides and loosen heater mounting screws.

Note:

If you bump the touch guard, press the CLEAR button on the controller box to reset.

Choosing The Platen

Be sure to use the proper platen. Use the hard rubber platens for printing, and the soft rub-

ber platen for heat sealing and dry ink transfers. There should be a distance of at least 1/8”

to 1/4” between the printed image and the outer edge of the platen.

Содержание Deco-Print DP2000T

Страница 13: ...thermopatch com 13 Step 5 Refer to below Place flange assemblies Item A on supply and take up shafts Item B...

Страница 14: ...thermopatch com 14...

Страница 15: ...thermopatch com 15...

Страница 41: ...thermopatch com 41 Drawing 15 Electronics Module Drawing 16 Main Electronics Module...

Страница 42: ...thermopatch com 42 Drawing 17 AC Harness...

Страница 43: ...thermopatch com 43 Drawing 18 DC Harness...