29

Combustion and Ventilation Air Supply

The furnace and venting system require a generous amount of clean air to operate

safely. Lack of adequate combustion and ventilation air can result in erratic operation of

the burner, noisy and poor combustion, sooting of the combustion chamber, and fuel

odors in the air.

Never block off or restrict the supply of air to the furnace.

Inspection Areas

Burner Compartment:

On the counterflow / horizontal furnace models,

the burner

compartment can be inspected by removing the front door of the furnace. Look for signs

of excessive heat, such as discoloration of components, damage to material from rust or

corrosion, soot or carbon build-up, and evidence of fuel oil leakage.

Exterior of Furnace:

The exterior of the furnace should be inspected for signs of

excessive heat such as discoloration of materials and damage from rust or corrosion.

Confirm the base or frame supporting the furnace in level and in sound condition.

Venting System:

The furnace flue pipe, vent connector, barometric damper, and

chimney should be inspected for:

Signs of excessive rust, corrosion pitting, and holes.

Signs of condensation or moisture leakage.

Evidence of structural damage, and loose or disconnected piping joints.

Presence animal nests.

Free movement of the vane of the barometric damper without binding or

interference.

If any problems are evident, call a qualified heating contractor for assistance.

NOTICE: A qualified heating contractor MUST service the oil burner and inspect

the heat exchanger in this furnace at least once a year.

Содержание OD6FA072D48

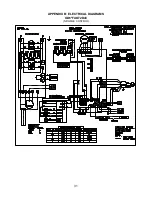

Страница 32: ...31 APPENDIX B ELECTRICAL DIAGRAMS OD6 FAO72D48 NRGMAX CONTROL...

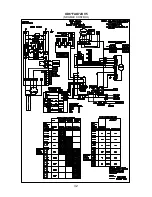

Страница 33: ...32 OD6 FAO72DV5 NRGMAX CONTROL...

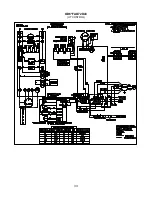

Страница 34: ...33 OD6 FAO72D48 UT CONTROL...

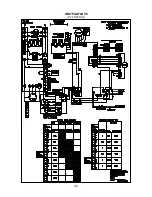

Страница 35: ...34 OD6 FAO72DV5 UT CONTROL...

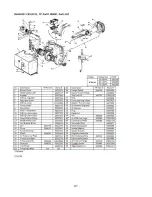

Страница 37: ...36 APPENDIX D REPLACEMENT PARTS OD6FA072D48 OD6FA072DV4...

Страница 38: ...37...

Страница 39: ...38 OD6RA072D48 OD6RA072DV4...

Страница 40: ...39...

Страница 41: ...40...

Страница 42: ...41...

Страница 43: ...42...