21

Instructions to Our Customer / End User

! WARNING: If the burner does not operate properly after depressing the oil

primary reset button, turn off the electrical power to the furnace and close the

manual oil shutoff valve. Immediately contact a qualified heating contractor for

service.

Before leaving a new installation, the installer should show the customer or end user

where the furnace instruction manual is kept. He should also discuss the following points:

1) Describe the general operation of the furnace and, if properly equipped, the

cooling system.

2) Show the location of the furnace air filter(s) and those in the duct system, if

equipped. Demonstrate how to remove, clean, and replace the air filter(s).

3) Demonstrate how to set and adjust the room air temperature using the room

thermostat.

4) Demonstrate how to operate (turn on and off), the heating system and, if properly

equipped, the cooling system and the circulating air blower.

5) Show the location of the oil primary safety control in the furnace. Describe when

and demonstrate how to depress the oil primary reset button.

SERVICE

Control Diagnostics

The control boards are equipped Input Status LEDs. These are intended to provide a

quick view into furnace performance without requiring a voltmeter.

UT Control

Normal Operation Indicators

Thermostat Inputs: Green LEDs indicate 24V signal present at terminal.

Status: Red LED is on solid to indicate valid input signal. In Standby Red

LED is off.

Fault LED Indicator

Limit: Red LED will flash rapidly while 120VAC is missing from the limit

switch.

NRG Max Control

Normal Operation Indicators

Thermostat Inputs: Amber LEDs indicate 24V signal present at terminal

Status: Blue LED pulses at various speeds to indicate operational state

24V Transformer: Green LED indicates that 24V transformer is powered

Blower: Green LED indicates Blower Relay is energized

Burner: Green LED indicates Burner TT Relay is energized

Fault LED Indicator

Limit: Red LED indicates that High Limit is Open

Содержание OD6FA072D48

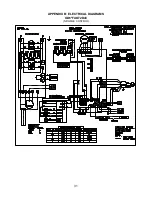

Страница 32: ...31 APPENDIX B ELECTRICAL DIAGRAMS OD6 FAO72D48 NRGMAX CONTROL...

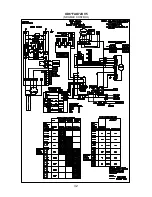

Страница 33: ...32 OD6 FAO72DV5 NRGMAX CONTROL...

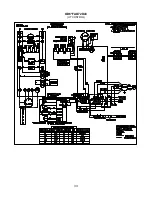

Страница 34: ...33 OD6 FAO72D48 UT CONTROL...

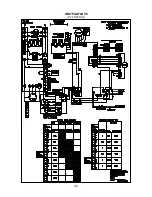

Страница 35: ...34 OD6 FAO72DV5 UT CONTROL...

Страница 37: ...36 APPENDIX D REPLACEMENT PARTS OD6FA072D48 OD6FA072DV4...

Страница 38: ...37...

Страница 39: ...38 OD6RA072D48 OD6RA072DV4...

Страница 40: ...39...

Страница 41: ...40...

Страница 42: ...41...

Страница 43: ...42...