ECO ULTRA Electric Boiler

Installation, Use and Care Manual

(Revision June 2017)

, Page

12.

3.6 SYSTEM SETUP

Figures 2 to 8 indentify and show location of the

different components. They also provide typical

heating system installation. External components

location may vary in order to accommodate

specific installation and local codes and

regulation.

3.6.1 Connecting the boiler

The boiler heating supply and return connections

are located on the left or right side and are

1”

NPTM for Model 50 and 1-

¼’’ NPTM for model

70. The connections at the left or right can be

used. The important thing is that the fluid

circulation must be made from the bottom to the

top (see figure 1)

Unions are recommended on the inlet and outlet

pipes to disconnect the water heater easily for

servicing if necessary.

Dielectric (insulating) unions should be used if

copper-steel connections are made.

Insulate all pipes containing hot water, especially

in unheated areas.

3.6.2 Flow-check valve

If the heating system uses a single or multiple

circulators without motorized zone valves,

a flow-

check valve must be installed

to avoid all

possibility of gravity flow and heat loss during

non-draw periods. Modern circulators are

typically provided with spring loaded check valves

that will provide adequate protection.

If the heating system uses motorized zone

valves, these will provide adequate protection.

3.6.3 Pressure relief valve

The boiler is delivered with a factory installed tank

pressure relief valve set at 207 kPa (30 psi).

NEVER

replace the pressure relief valve by a

higher set pressure one.

Connect the outlet of the relief valve downward

toward a safe location.

Relief valve outlet pipe diameter must not be of

smaller diameter than the relief valve outlet. The

oulet pipe end must be visible in order to observe

any relief incident and be protected from freezing.

NEVER cap or plug a pressure relief valve

outlet. The pressure relief valve is a safety

apparatus and preventing its proper operation

may cause death, injury or property damage.

3.6.4 Expansion tank

When operating the ECO ULTRA and the heating

system, pressure will vary between 83 kPa and

193 kPa (12 psi to 28 psi). The operating

pressure is affected by the type of heating system

and the size of the expansion tank installed.

The expansion tank is used to absorb the

increase of water volume from the boiler and the

system when it is working.

The model selection should be based on the

maximum working temperature and the water

volume of the total system. For example, a

system with radiators contains much more water

volume than a baseboards system. Likewise, the

ECO ULTRA also contains an important volume

of water that has to be added :

ECO ULTRA 50 : 48 usgal

ECO ULTRA 70 : 71 usgal

With this information, the installator or distributor

should be able to make an appropriate selection

for an expansion tank.

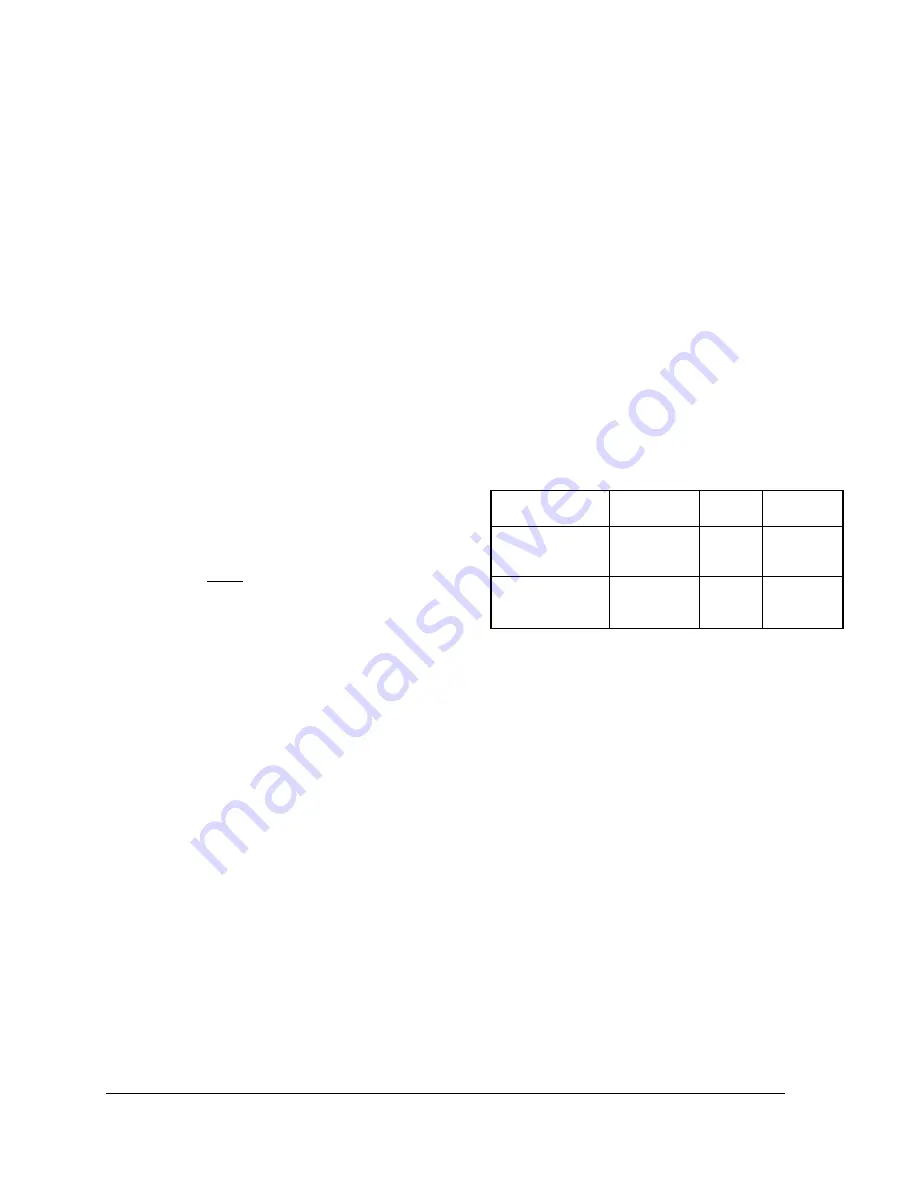

Here are some minimal recommendations for

different types of heating systems.

ECO ULTRA

Baseboards

Radiant

floor

Cast-iron

radiators

ECO ULTRA 50

#30

#30

#60

ECO ULTRA 70

#60

#60

#90

The expansion tank is generally installed on the

wall or ceiling. It also has to be well supported.

3.6.5 Water pressure regulator

The boiler should be installed in such a way that

it can automatically be fed with water in the event

of a pressure drop.

The minimum pressure obtained when the

system is cold is generally 12 psi (83 kPa).

This accessory shall be equipped with one or

more check valves to avoid all possibilities of the

boiler water returning to the potable water supply

network (local regulation should be applied)

3.6.6 Automatic Air Vent

The ECO ULTRA has a factory installed tank

automatic air vent. This air vent function is to vent

any air present in the tank.

For proper operation, do not cap or block the air

bleeder outlet.

For proper operation of the heating system, it may

be necessary to add air bleeders to the heating

system circuits.