29

Maintenance

Checking Compressor Oil Level

The oil level should be visible in the sight glass while

the compressor is running. If adding oil, use only

approved Polyol Ester oil, or Solest 170.

Cleaning the Operator Interface

Use of abrasive cleaners or solvents may damage the

window. Do not scrub or use brushes. To clean the

display window:

1.

Disconnect power from the terminal at the

power source.

2.

Using a clean sponge or a soft cloth, clean the

display with a mild soap or detergent. If paint or

grease splash is present, remove before drying

by rubbing lightly with isopropyl alcohol.

Afterward, provide a final wash using a mild

soap or detergent solution. Rinse with clean

water.

3.

Dry the display with a chamois or moist cellulose

sponge to avoid water spots.

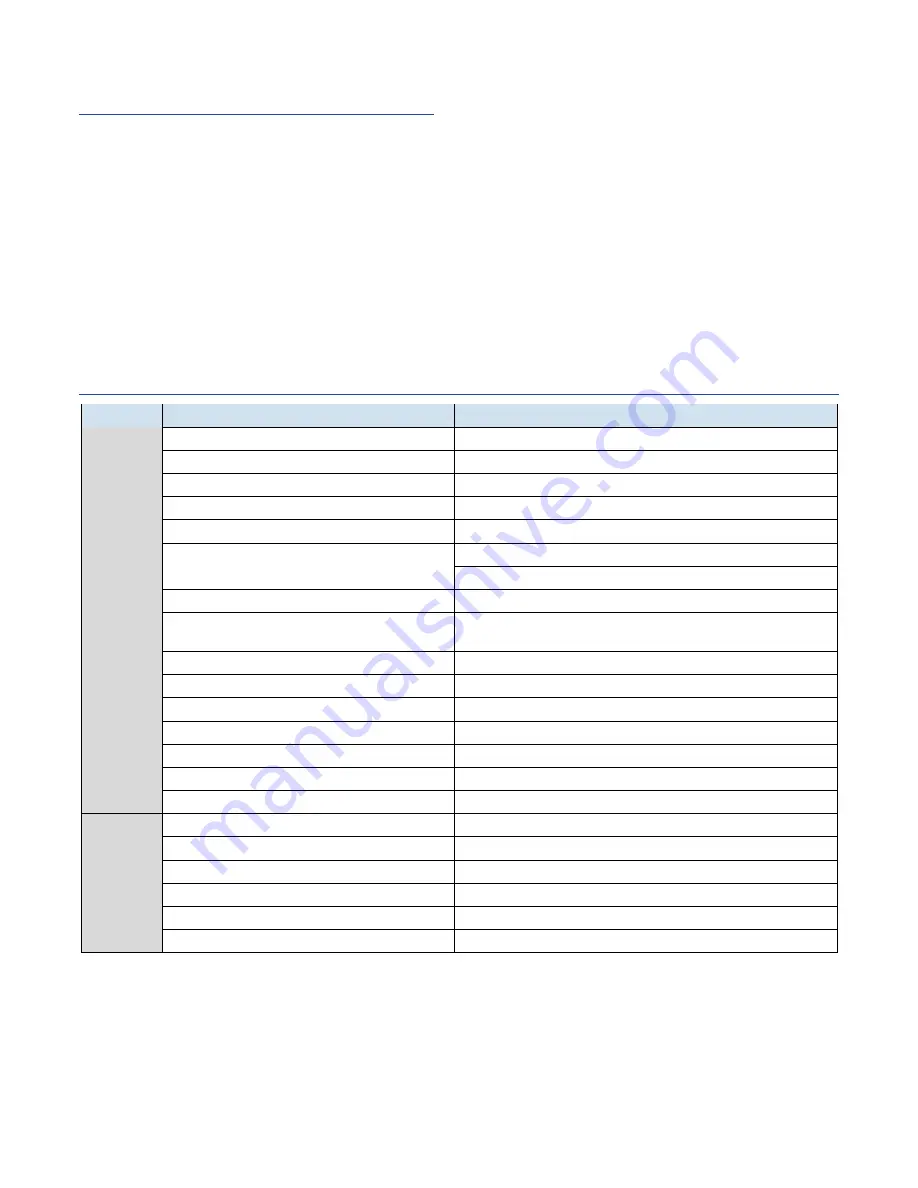

General Troubleshooting

Problem

Possible Cause

Remedy

Compressor

will not start

Compressor Motor Protection Module

Reset module, cycle power for five seconds

Incorrect three-phase rotation

Correct phasing of incoming power

Loss of phase

Check incoming power

High motor temperature

Check oil level, superheat, liquid injection

High oil / discharge temperature

Check oil level, superheat, liquid injection

Low compressor oil level

Add oil as required

Replace oil level switch if faulty

Three-phase power monitor tripped

Correct phasing of incoming power

Compressor overload

Check supply voltage, amperage, contactor, wiring, and overload set

point

Compressor contactor

Replace if faulty

Microprocessor output relay

Replace if faulty

Compressor failure

Contact Customer Service Department for assistance

No flow

Low flow through evaporator

Adjust flow to proper level

Clogged Y-Strainer

Clean Y-Strainer

Clogged evaporator

Back flush / clean evaporator

Flow Switch

Replace if faulty

Freezestat

Low flow through evaporator

Adjust flow to proper level

Clogged Y-strainer

Clean Y-Strainer

Clogged evaporator

Back flush / clean evaporator

Freezestat setting

Check for proper setting

Sensor

Replace if faulty

Microprocessor sensor input

Replace if faulty