4

2 February, 2005 Code Sheet V4.01d (NZ1001)

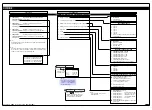

Tiger 380 Series Code Logic Diagram

To enter press the

and

buttons at the same time

Calibration Modes for Inputs and Outputs

Code 1 – Display Configuration

Code 2 – Sampling Rate & CH1 Measurement Task

Code 3 – CH1 Post Processing Functions

Code 4 – CH2 Functions

Code 5 – CH3 Functions

Code 6 – CH4 Functions

Code 7 – Result Processing

Code 8 – Data Logging & Printer Options

Code 9 – Functions for Digital Input Pins

[ CAL ]

[CODE_1]

[CODE_2]

[CODE_3]

[CODE_4]

[CODE_5]

[

CODE_6]

[CODE_7]

[CODE_8]

[CODE_9]

To enter press the

and

buttons at the same time

Setpoint 1

[SP_1]

Setpoint Activation Values Mode

Setpoint 2

[SP_2]

Setpoint 3

[SP_3]

Setpoint 4

[SP_4]

Setpoint 5

[SP_5]

Setpoint 6

[SP_6]

Enter these menus to set setpoint

(SP) activation values

Setpoint 1

[SPC_1]

Setpoint & Relay Control Settings Mode

Setpoint 2

[SPC_2]

Setpoint 3

[SPC_3]

Setpoint 4

[SPC_4]

Setpoint 5

[SPC_5]

Setpoint 6

[SPC_6]

Enter these menus to configure SP control

settings

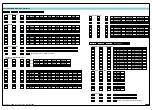

See Pages 5 to 7 for calibration settings to perform the following calibration functions

on input and output signals (The first 5 functions are activated by pressing Prog.):

See Page 8 for code settings to configure:

See Page 9 for code settings to configure the following:

• Analog sampling rate and control output rate for all seven channels.

• CH1 Measurement task (input signal type and range selection for CH1).

See Page 10 for code settings to configure the following CH1 post processing

functions:

• Direct signal, square root, or inverse of CH1.

• Apply selected linearization table to CH1 signal.

See Page 10 for code settings to configure CH2 when using dual input

signal conditioners:

• Direct signal, square root, or inverse of CH2 voltage or current input.

• CH2 Measurement task (input signal type and range selection for CH2).

• Apply selected linearization table to CH2 signal.

See Page 11 for code settings to configure data logging and data print-

ing from the controller.

See Page 11 for code settings to configure the inputs from external

sources through the following digital input pins on the rear of the con-

troller:

• Display test pin.

• Hold pin.

• Lock pin.

The

Setpoint and

Relay Control

Settings

diagram

on Pages 12 to 14

shows the three

digit configuration

settings that are

applied individually

to each setpoint.

Display Brightness

[ BRI ]

Allows you to adjust the display brightness in a range of 8 settings. 0 being dull,

7 being bright.

Main Programming Mode

Setpoint Programming Mode

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

OPERATIONAL DISPLAY

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

OPERATIONAL DISPLAY

Default setting = 18000

Default setting = –18000

Default setting = 5000

Default setting = –5000

Default setting = 10000

Default setting = –10000

• Tare.

• Single point auto calibration.

• 2-point auto calibration.

• Primary input compensation.

• Manual loader.

• Manual calibration.

• 2-point calibration.

• Thermocouple calibration.

• RTD calibration.

• Set up serial output.

• Set up auto zero maintenance settings.

• Set up averaging samples & averaging window.

• Set K factor & cutoff for totalizers.

• Set up four 32-point linearization tables.

• Analog output scaling.

• Tendency indication thru SP1 & SP2 annunciators (shows rising / falling signal).

• Indication of setpoints / relays operation thru dedicated annunciators.

• Selecting the data source for the display and peak / valley 1 to 3.

• Selecting last digit rounding.

• Selecting display units.

• Selecting decimal point position.

• Display manual loader.

• Display with selected update rates (display shows selected register).

See Page 10 for code settings to configure CH3 when using triple input

signal conditioners:

• Direct signal, square root, or inverse of CH3 voltage or current input.

• CH3 Measurement task (input signal type and range selection for CH3).

• Apply selected linearization table to CH3 signal.

See Page 11 for code settings to configure CH4 when using quad input

signal conditioners:

• Direct signal, square root, or inverse of CH4 voltage or current input.

• CH4 Measurement task (input signal type and range selection for CH4).

• Apply selected linearization table to CH4 signal.

See Page 11 for code settings to configure the controller for processing

the result of CH1 and CH2:

• Direct signal, square root, or inverse of Result signal.

• Apply selected linearization table to Result signal.

• Maths functions for Result (CH1and CH2).