Page 11

Apr-18-2016 DI-60A 320 DS (NZ302)_UL April 2016

Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

Initial Setup Procedures

Initial Setup Procedures

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

TEXMATE

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

MODEL &

SOFTWARE CODE

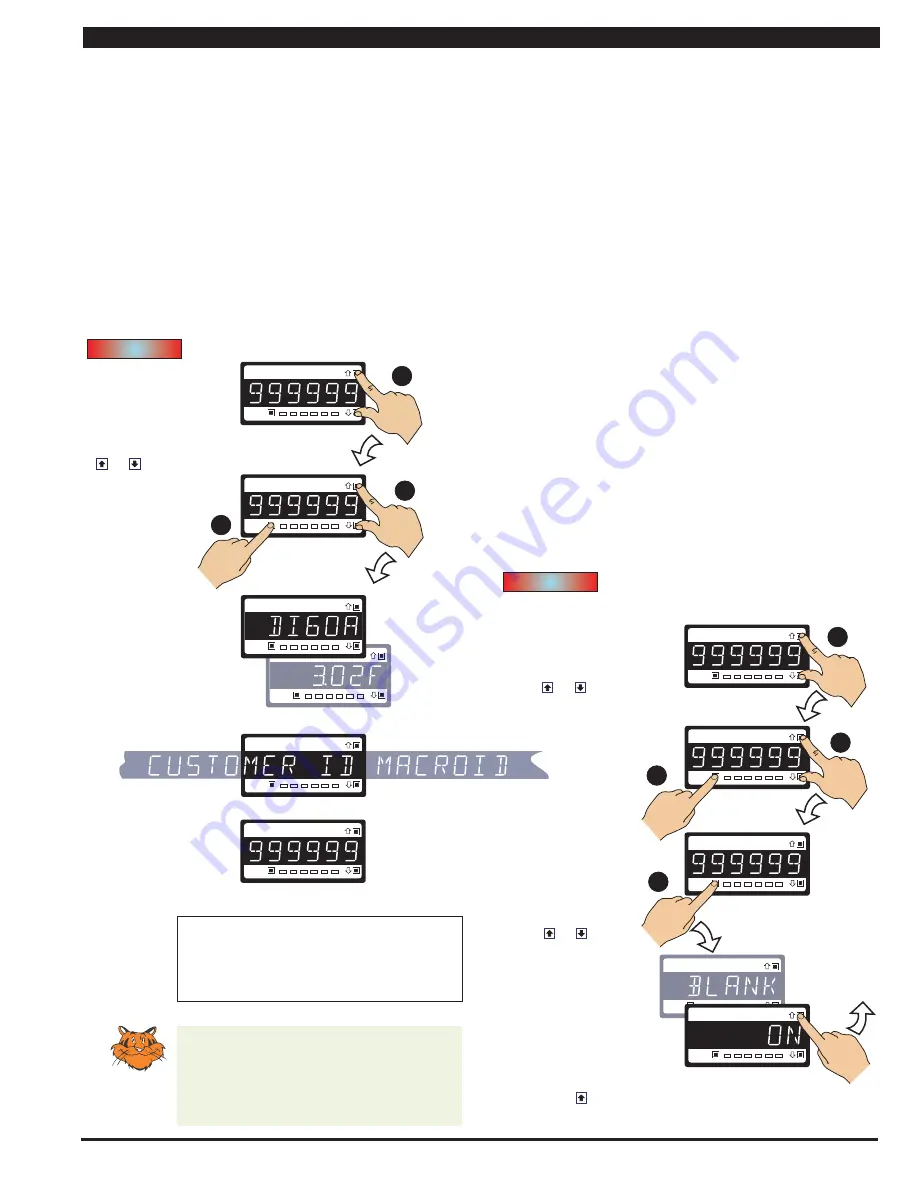

VERSION CHECK

Press

and

hold

Step 1

Step 2

Step 3

The displays toggle three

times. If a macro is installed

and turned on, the customer ID

and the macro ID scroll across the

display before returning

to the operational display.

Operational Display

Operational Display

Example

Release

after

pressing

Prog.

Press

then

once

release

Model

Number

Typical

Software

Version

Number

Press and hold

the and

buttons

While holding both

buttons, press the Prog.

button then release

all three buttons

Programming Tip

The

Model and Software Code Version

check-

ing procedure can be performed at any

time without interfering with other configu-

ration settings.

START HERE

The meter model and software code version number can be

checked at any time while in the operational display using the

following procedure.

Before configuring the meter, carry out the following meter

configuration checks:

• Model and software code version check.

• Code blanking and macro check.

After powering-up the meter, check the model and software

code version number and note this in your user manual.

Code Blanking and Macro Check

Tiger 320 Series meters have the ability to hide (blank out) all or

some programming codes, making them tamper-proof. This can

only be done using the Meter Configuration program.

With code blanking turned ON, all main and setpoint codes that

have been blanked out during factory programming are hidden,

preventing them from being reprogrammed. Any codes that have

not been blanked out are still visible and can be reprogrammed.

Turning code blanking OFF means all meter programming

codes are visible when you enter the programming modes and

can be reprogrammed.

A macro is a set of commands that run automatically when the

meter is powered up. We have a growing library of macros to suit

a wide range of standard customer applications.

Macros can be installed in the meter at the factory during initial

programming or by the customer at some later date. Macros are

written and compiled using the BASIC Compiler program, and

loaded into the meter using either the BASIC Compiler program

or the Meter Configuration program.

Turning the macro OFF means that the meter will not per-

form the automatic commands pre-programmed to run with

the macro.

Unless requested to blank out all or some programming codes

and/or run a macro, we will program the meter in the code blank-

ing OFF and macro OFF (default) setting.

To turn the code blanking and macro settings from ON to OFF:

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Press

and

hold

Step 1

Step 2

While holding both

buttons, press the Prog.

button.

Step 2

Step 3

Operational Display

Example

Release

after

pressing

Prog.

Press

Code

Blanking

CODE BLANKING & MACRO CHECK PROCEDURE

Press and hold

the and

buttons

While holding both

buttons, press the Prog.

button.

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Release the

the and

buttons and hold

the Prog. button

for approx. 1 sec

then release

Release

after 1

sec

Prog.

SP1

SP2

SP4

SP3

SP5

SP6

Step 4

Press the button to switch

code blanking OFF

Press

1

NOTE: Unless otherwise

requested, the factory

default setting is oFF

Code Blanking & Macro

Check Procedure

continued on next page

(Step 5)

START HERE

CODE BLANKING

& MACRO CHECK

PROCEDURE

a

b

c

d

a

b

c

Model No:

.............................................................................

Software Version No:

...................................................

Customer ID:

......................................................................

Macro ID:

..............................................................................

Model and Software Code Version Check