Page 28

Heating connections

The relevant laws, regulations and standards for machi-

ne room piping and for heat pump systems must also be

observed.

It is essential that a dirt trap is fitted in the heating

•

return pipe.

Safety devices and expansion devices for closed hea-

•

ting systems according to EN 12828 must be fitted.

Pipe dimensions must conform to the required flow

•

volumes (see section 2.5, Technical data, page 5).

Connection hoses supplied for the heat pump intake

•

and return lines must always be installed. The connec-

tion hoses can be cut to the required length, but not

shorter than 60 cm. In addition, the connection hoses

must not be bent.

Venting options should be fitted at the highest points of

•

the connection lines, and draining options at the lowest

points.

To avoid heat loss connection lines should be insulated

•

using suitable material.

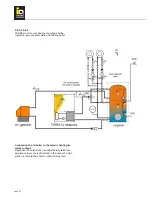

Oxygen diffusion

With plastic pipe underfloor heating or open heating sys

-

tems which are not diffusion-tight, corrosion may occur

on steel parts when using steel pipes, steel radiators or

storage tanks due to oxygen diffusion.

Corrosion products can be deposited in the condenser

and may cause heating losses to the heat pump or high-

pressure faults.

For this reason, open heating systems or steel pipe

installations in combination with plastic pipe underfloor

heating which is not diffusion-tight should be avoided.

Heating water quality

Depending on the quality of the heating water, limescale

may occur (adherent coating primarily consisting of calci-

um carbonate) on heat exchanger surfaces in particular,

i.e. with a high proportion of calcium hydrogen carbonate

there is a risk of limescale forming.

For this reason in systems with a water hardness of over

14°dH or with a calcium hydrogen carbonate concentrati-

on of more than 2.5 mol/m³, the heating water should be

treated accordingly (softened/demineralised).

Information on the calcium hydrogen carbonate con-

centration c(Ca(HCO3)2) of your heating water can be

obtained from your water supply company.

The pH value should also be checked; this should be

between 8 and 9.5.

EN 12828

ÖNORM H 5195

VDT Directive no. 2034-1

Incorrect flow volumes due to incorrect

pipework, incorrect fittings or incorrect

pump operation may cause damage.