20 GTH-4016SR • GTH-4018SR Part No. 57.4400.9203

March 2010

Section 3 • Scheduled Maintenance Procedures

REV A

A-4

Machine Greasing

NOTICE

Genie specifications require that

this procedure be performed every

8 hours or daily, whichever comes

first.

Greasing the specified locations is essential for

good machine performance and service life.

Operating the machine with little or no grease

may cause the machine to perform poorly and

continued use may cause component damage.

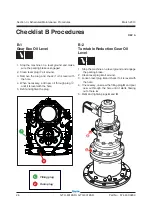

1 Fully extend the boom. Raise the boom as

needed.

2 Locate the grease fittings at both sides of all

boom tubes except the innermost tube. Refer

to the illustration.

3 Pump grease into the fittings until the inner

boom rollers are thoroughly lubricated.

4 Lubricate the top boom tube wear pads.

NOTICE

Do not lubricate the side wear

pads at the boom rollers, if

equipped.

5 Return the boom to the stowed position.

6 Locate a grease fitting at one of the locations

shown in the illustration.

7 Pump grease into the fitting until the joint is

thoroughly lubricated.

8 Repeat this procedure, beginning with step 6,

for each remaining grease fitting shown in the

illustration.

9 Locate the grease fittings on the stabilizer

frame at the front of the machine.

10 Pump grease into each fitting until the joints are

thoroughly lubricated.

11 Locate the grease fittings on the outriggers at

the front of the machine.

12 Pump grease into each fitting until the joints are

thoroughly lubricated.

Grease Speci

fi

cation

PTFE INTERFLON FIN GREASE LS 2

CHECKLIST A PROCEDURES

Содержание Genie GTH4016 SR

Страница 4: ...iv GTH 4016SR GTH 4018SR Part No 57 4400 9203 March 2010 Intentionally blank page ...

Страница 12: ...xii GTH 4016SR GTH 4018SR Part No 57 4400 9203 March 2010 Intentionally blank page ...

Страница 92: ...80 GTH 4016SR GTH 4018SR Part No 57 4400 9203 March 2010 Section 5 Settings REV A Intentionally blank page ...

Страница 124: ......